Abstract

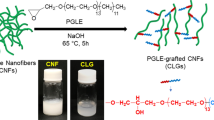

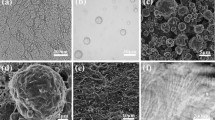

Poor water solubility of cellulose acetate is a key factor limiting its application in leather finishing field. Herein, a self-emulsifying aqueous emulsion was synthesized by using cellulose diacetate (CDA) as the substrate, dimethylolbutyric acid (DMBA) as the hydrophilic agent, and hexamethylene diisocyanate (HDI) as the bridging agent. Because the flexible carbon chain of HDI has the advantages of easy bending and deformation, the problem of large steric hindrance and low reactivity of -OH during water-based CDA can be solved by using the method of converting reactive functional groups and transferring reactive sites. At the same time, the flexible molecule 1,4-butanediol (BDO) and propylene glycol polyether (N210) are used as chain extenders to increase the molecular stretch and curl ability by adjusting the ratio of molecular soft and hard segments, and improve emulsion stability and coating flexibility. And through the reaction of -NH2 and -NCO on the surface of nano SiO2 modified by KH550, the nano SiO2 is evenly distributed in the CDA water-based polymer to improve the comprehensive performance of the emulsion coating. Thus the nano-SiO2 modified cellulose acetate water-based polymer emulsion (SiO2/WCDA) is obtained for leather finishing. The emulsion particles show an oil-in-water (O/W) core–shell structure, and the average particle size and dispersion coefficient (PDI) of the particles are 88.79 nm and 0.150, respectively. The surface of the coating film is compact, flat, and hydrophobic, with the contact angle is 104.3 °. In addition, the coating film has good adhesion, water resistance, heat resistance, yellowing resistance, chemical resistance, flexibility and mechanical properties.

Similar content being viewed by others

References

Aguirresarobe RH, Martin L, Aramburu N, Irusta L, Fernandez-Berridi MJ (2016) Coumarin based light responsive healable waterborne polyurethanes. Prog Org Coat 99:314–321

Bao Y, Shi C, Yang Y, Ma J, Sha R (2015) Effect of hollow silica spheres on water vapor permeability of polyacrylate film. RSC Adv 5(15):11485–11493

Bolden AL, Kwiatkowski CF, Colborn T (2015) New look at BTEX: are ambient le-vels a problem. Environ Sci Technol 49(9):5261–5276

Candido RG, Goncalves AR (2016) Synthesis of cellulose acetate and carboxymethylcell-ulose from sugarcane straw. Carbohyd Polym 152:679–686

Chen J, Xu J, Wang K, Cao X, Sun R (2016) Cellulose acetate fibers prepared from diff-erent raw materials with rapid synthesis method. Carbohyd Polym 137:685–692

Elsayed H, Attia R, Mohamed O, Haroun A, El-Sayed N (2018) Preparation of polyureth-ane silicon oxide nanomaterials as a binder in leather finishing. Fibers Polym 19:832–842

Etemadi H, Yegani R, Babaeipour V (2016) Study on the reinforcing effect of nanodia-mond particles on the mechanical, thermal and antibacterial properties of cellulose a-cetate membranes. Diam Relat Mater 69:166–176

Fallah F, Khorasani M, Ebrahimi M (2017) Improving the mechanical properties of water-borne nitrocellulose coating using nano-silica particles. Prog Org Coat 109:110–116

Fan Y, Du Z, Chen W, Wang X (2009) The development and prospect of leather finishing. Leather Chem 06:9–21

Han Y, Hu J, Xin Z (2019) Facile preparation of high solid content waterborne polyureth-ane and its application in leather surface finishing. Prog Org Coat 130:8–16

Hu J, Ma J, Deng W (2008) Properties of acrylic resin/nano-SiO2 leather finishing agent prepared via emulsifier-free emulsion polymerization. Mater Letter 62(17–18):2931–2934

Hu J, Peng K, Guo J, Shan D, Kim GB, Li Q, Gerhard E, Zhu L, Tu W, Lv W, Hick-ner MA, Yang J (2016) Click crosslinking improved waterborne polymers for environment-friendly coatings and adhesives. ACS Appl Mater Interfaces 8(27):17499–17510

Jing H, Ma J, Deng W (2008) Properties of acrylic resin/nano-SiO2 leather finishing agent prepared via emulsifier-free emulsion polymerization. Mater Lett 62(17–18):2931–2934

Jogunola O, Eta V, Hedenstrm M, Sundman O, Mikkola J-P (2016) Ionic liquid mediated technology for synthesis of cellulose acetates using different cosolvents. Carbohyd P-Olym 135:341–434

Kang J (2012) Waterborne polyacrylate leather finishing agent. China Patent CN 102807798A

Kothandam R, Pandurangan M, Jayavel R, Gupta S (2016) A novel nano-finish formulat-ions for enhancing performance properties in leather finishing applications. J Clust Sci 27:1263–1272

Lee H, Nishino M, Sohn D, Lee JS, Kim IS (2018) Control of the morphology of cell-ulose acetate nanofibers via electrospinning. Cellulose 25:2829–2837

Liu J, Ma J, Bao Y, Zhu Z, Zhang J, Ma Y (2011) Effect of long-chainacrylate on theproperties of polyacrylate/Nano-SiO2 composite leather finishing agent. Polym-plastTechnol 50(15):1546–1551

Liu J, Ma J, Bao Y, Wang J, Tang H, Zhang L (2014) Polyacrylate/surface-modified ZnO nanocomposite as film-forming agent for leather finishing. Int J Polym Mater Po 63(16):809–814

Ma J, Hu J, Yang Z (2007) Preparation of acrylic resin/nano-SiO2 for leather finishing agent. Mater Manuf Process 22(6):782–786

Puls J, Wilson SA, Hölter D (2011) Degradation of Cellulose Acetate-Based Materials: AReview. J Polym Environ 19(1):152–165

Su X, Chen Z, Zhang Y (2017a) Preparation and characterization of waterborne cellulose e-mulsion ased on nitrocellulose modified with acrylic copolymer. Chem Pap 7:2145–2152

Su X, Zhang Y, Zhao D, Chen Z (2017b) Synthesis and characterization of carboxylate wa-terborne cellulose emulsion based on cellulose acetate. Cellulose 24(5):1–9

Tamilselvia A, Jayakumarb GC, Charanc KS, Sahub B, Deepad PR, Kantha SV, Kan-agaraje J (2019) Extraction of cellulose from renewable resources and its application-in leather finishing. J Clean Prod 230:694–699

Wang X, Lu X, Qiang T, Ren L (2010) Preparation and application properties analysis of hyperbranched polyurethane leather finishing agent. Adv Mater Res 129–131:251–255

Wang C, Ma C, Mu C, Lin W (2017) Tailor-made zwitterionic polyurethane coatings: mic-rostructure, mechanical property and their antimicrobial performance. Rsc Adv 7(44):27522–27529

Wang W, Liang T, Bai H, Dong W, Liu X (2018) All cellulose composites based on cell-ulose diacetate and nanofibrillated cellulose prepared by alkali treatment. Carbohyd Polym 179:297–304

Yang Z, Zang H, Wu G (2019) Study of solvent-free sulfonated waterborne polyurethan-e as an advanced leather finishing material. J Polym Res 26:213

Yu Y, Liao B, Li G, Jiang S, Sun F (2014) Synthesis and properties of photosensiti-ve silicone-containing polyurethane acrylate for leather finishing agent. Ind Eng Chem Res 53(2):564–571

Zhao X, Wang H (2015) Research status of water-based nitrocellulose emulsion. Leather and Chemicals 32(04):12–16

Zhou H, Wang H, Niu H, Zhao Y, Xu Z, Lin T (2017) A waterborne coating system for preparing robust, self-healing, superamphiphobic surfaces. Adv Funct Mater 27(14):1604261.1-1604261.8

Acknowledgments

This work was supported by the National Natural Science Foundation of China (21878181), Youth Talent Support Program of Science and Technology Association of Shaanxi University (20200611), Natural Science Basic Research Project of Shaanxi Provincial Department of Science and Technology (2021JQ-826) and Scientific Research Program Project of Weinan Normal University (20RC+9).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Bao, Y., Guo, M. et al. Preparation and properties of nano SiO2 modified cellulose acetate aqueous polymer emulsion for leather finishing. Cellulose 28, 7213–7225 (2021). https://doi.org/10.1007/s10570-021-03901-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03901-y