Abstract

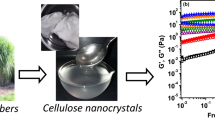

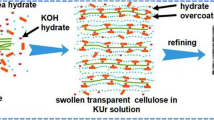

Cellulose nanofibrils (CNFs) are normally available and used as aqueous suspensions. Total understanding of the rheological characteristics of CNF suspensions, however, remains a tremendous challenge. The main objective of this study is to investigate the structure-morphology-rheology relationships for CNFs as a function of phosphorylation duration. For that purpose, phosphorylated CNFs have been produced from jute fibers (Corchorus olitorius) with controlled curing times of the source materials and reported for the first time. The resulting fibers have a width in the range of 21–42 nm. It was observed that the morphological structure, crystallinity, surface charge, surface chemistry, and rheological property of the extracted CNFs were greatly influenced by the phosphorylation. The obtained CNF systems displayed a viscoelastic gel-like behavior because of the formation of highly entangled fibers structure. Results show that all CNF suspensions exhibit shear-thinning behavior. Both steady-state and dynamic rheology revealed that the characteristics of aqueous suspensions strongly changed depending on the phosphorylation. Finally, schematic modeling was proposed to demonstrate the transformation of the gel structure with curing time applied to the CNFs.

Similar content being viewed by others

References

Agoda-Tandjawa G, Durand S, Berot S, Blassel C, Gaillard C, Garnier C, Doublier J-L (2010) Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohyd Polym 80:677–686

Benhamou K, Dufresne A, Magnin A, Mortha G, Kaddami H (2014) Control of size and viscoelastic properties of nanofibrillated cellulose from palm tree by varying the TEMPO-mediated oxidation time. Carbohydr Polym 99:74–83

Blanco A, Monte MC, Campano C, Balea A, Merayo N and Negro C (2018) Nanocellulose for industrial use: cellulose nanofibers (CNF), cellulose nanocrystals (CNC), and bacterial cellulose (BC). In: Handbook of nanomaterials for industrial applications pp 74–126, Elsevier.

Charani PR, Dehghani-Firouzabadi M, Afra E, Shakeri A (2013) Rheological characterization of high concentrated MFC gel from kenaf unbleached pulp. Cellulose 20:727–740

Daicho K, Saito T, Fujisawa S, Isogai A (2018) The crystallinity of nanocellulose: dispersion-induced disordering of the grain boundary in biologically structured cellulose. ACS Appl Nano Mater 1:5774–5785

Fernandes Diniz JMB, Gil MH, Castro JAAM (2004) Hornification—its origin and interpretation in wood pulps. Wood Sci Technol 37:489–494

Fiss BG, Hatherly L, Stein RS, Friščić, Moores A (2019) Mechanochemical phosphorylation of polymers and synthesis of flame-retardant cellulose nanocrystals. ACS Sustain Chem Eng 7:7951–7959

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

French AD (2020) Correction to: increment in evolution of cellulose crystallinity analysis. Cellulose 27:9135–9136

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20:583–588

Ghanadpour M, Carosio F, Larsson PT, Wågberg L (2015) Phosphorylated cellulose nanofibrils: a renewable nanomaterial for the preparation of intrinsically flame-retardant materials. Biomacromol 16:3399–3410

Granja P, Pouysegu L, Petraud M, De Jeso B, Baquey C, Barbosa M (2001a) Cellulose phosphates as biomaterials. I. Synthesis and characterization of highly phosphorylated cellulose gels. J Appl Polym Sci 82:3341–3353

Granja PL, Pouységu L, Deffieux D, Daudé G, De Jéso B, Labrugère C, Baquey C, Barbosa MA (2001b) Cellulose phosphates as biomaterials. II. Surface chemical modification of regenerated cellulose hydrogels. J Appl Polym Sci 82:3354–3365

Han J, Zhou C, Wu Y, Liu F, Wu Q (2013) Self-assembling behavior of cellulose nanoparticles during freeze-drying: effect of suspension concentration, particle size, crystal structure, and surface charge. Biomacromol 14:1529–1540

Hubbe MA, Tayeb P, Joyce M, Tyagi P, Kehoe M, Dimic-Misic K, Pal L (2017) Rheology of nanocellulose-rich aqueous suspensions: a review. BioResources 12(4):9556–9661

Illy N, Fache M, Menard R, Negrell C, Caillol S, David G (2015) Phosphorylation of bio-based compounds: the state of the art. Polym Chem 6:6257–6291

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19:137–145

Jia C, Bian H, Gao T, Jiang F, Kierzewski IM, Wang Y, Yao Y, Chen L, Shao Z, Zhu J (2017) Thermally stable cellulose nanocrystals toward high-performance 2D and 3D nanostructures. ACS Appl Mater Interfaces 9:28922–28929

Kalia S, Boufi S, Celli A, Kango S (2014) Nanofibrillated cellulose: surface modification and potential applications. Colloid Polym Sci 292:5–31

Klemm D, Cranston ED, Fischer D, Gama M, Kedzior SA, Kralisch D, Kramer F, Kondo T, Lindström T, Nietzsche S (2018) Nanocellulose as a natural source for groundbreaking applications in materials science: today’s state. Mater Today 21:720–748

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose-its barrier properties and applications in cellulosic materials: a review. Carbohyd Polym 90:735–764

Li M-C, Wu Q, Song K, Lee S, Qing Y, Wu Y (2015) Cellulose nanoparticles: structure–morphology–rheology relationships. ACS Sustain Chem Eng 3:821–832

Ling Z, Wang T, Makarem M, Santiago Cintrón M, Cheng HN, Kang X, Bacher M, Potthast A, Rosenau T, King H, Delhom CD, Nam S, Vincent Edwards J, Kim SH, Xu F, French AD (2019) Effects of ball milling on the structure of cotton cellulose. Cellulose 26:305–328

Luneva N, Ezovitova T (2014) Cellulose phosphorylation with a mixture of orthophosphoric acid and ammonium polyphosphate in urea medium. Russ J Appl Chem 87:1558–1565

Mishra RK, Sabu A, Tiwari SK (2018) Materials chemistry and the futurist eco-friendly applications of nanocellulose: status and prospect. J Saudi Chem Soc 22:949–978

Naderi A, Lindström T, Sundström J (2014) Carboxymethylated nanofibrillated cellulose: rheological studies. Cellulose 21:1561–1571

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromol 17:2311–2320

Noguchi Y, Homma I, Matsubara Y (2017) Complete nanofibrillation of cellulose prepared by phosphorylation. Cellulose 24:1295–1305

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8:1934–1941

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8:1934–1941

Rezayati Charani P, Dehghani-Firouzabadi M, Afra E, Shakeri A (2013) Rheological characterization of high concentrated MFC gel from kenaf unbleached pulp. Cellulose 20:727–740

Rol F, Belgacem MN, Gandini A, Bras J (2019) Recent advances in surface-modified cellulose nanofibrils. Prog Polym Sci 88:241–264

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Von Helmholtz H (1879) Studies of electric boundary layers. Wied Ann 7:337–382

Wanrosli W, Rohaizu R, Ghazali A (2011) Synthesis and characterization of cellulose phosphate from oil palm empty fruit bunches microcrystalline cellulose. Carbohyd Polym 84:262–267

Yang X, Han F, Xu C, Jiang S, Huang L, Liu L, Xia Z (2017) Effects of preparation methods on the morphology and properties of nanocellulose (NC) extracted from corn husk. Ind Crops Prod 109:241–247

Acknowledgments

The authors are grateful to the National Key R&D Program of China (Project No. 2018YFC2000900) and the Fundamental Research Funds for the Central Universities (Project No. 2232018A3-04).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patoary, M.K., Farooq, A., Zaarour, B. et al. Phosphorylated cellulose nanofibrils: structure-morphology-rheology relationships. Cellulose 28, 4105–4117 (2021). https://doi.org/10.1007/s10570-021-03786-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03786-x