Abstract

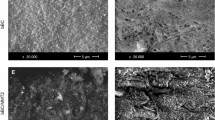

This work aims at the development and characterisation of bio-based active bi-layer films by solvent casting and electrospinning in order to be used for setting up active packaging solutions. Ethyl cellulose was used as the main material for the production of a layer on microfibrillated cellulose (MFC) films. This layer was formed with and without the incorporation of cinnamaldehyde (CNMA) which was used as antimicrobial compound. The MFC structures were obtained with a combination of different fibre dimensions and degree of fibrillation resulting in 16 different structures with porosities varying from 33 to 63%. A computational 3D simulation study of the porous structures was performed providing information about thickness, porosity and pore size uniformity and based on that a Picea abies-based MFC structure was selected. Structure characterization was evaluated using scanning electron microscopy, and pore dimensions were quantified using an image analysis tool. The bi-layer films chemical properties were studied using Fourier transform infrared spectroscopy and X-ray diffraction. Regarding barrier properties the bi-layer films produced by solvent casting were the ones showing a better barrier capacity. Both solvent casting and electrospinning processing showed to be useful to obtain a more hydrophobic surface (evaluated through contact angle measurements), being the higher values obtained for bi-layer films produced by electrospinning. Regarding colour parameters, the bi-layer films showed to be highly influenced by the production method and by the incorporation of CNMA. Regarding the antimicrobial activity, the bi-layer films with the incorporation of CNMA showed high antimicrobial activity against Listeria monocytogenes and Salmonella Typhimurium when the solvent casting method was used. Overall results showed that MFC-based films can be functionalised through the casting or electrospinning of ethyl cellulose solutions, aiming an antimicrobial and hydrophobic bi-layer film based on cellulose.

Graphical abstract

Similar content being viewed by others

References

Antunes MD, Dannenberg GS, Fiorentini ÂM et al (2017) Antimicrobial electrospun ultrafine fibers from zein containing eucalyptus essential oil/cyclodextrin inclusion complex. Int J Biol Macromol 104:874–882. https://doi.org/10.1016/j.ijbiomac.2017.06.095

Arfa AB, Preziosi-Belloy L, Chalier P, Gontard N (2007) Antimicrobial paper based on a soy protein isolate or modified starch coating including carvacrol and cinnamaldehyde. J Agric Food Chem 55:2155–2162. https://doi.org/10.1021/jf0626009

Armentano I, Del Gaudio C, Bianco A et al (2009) Processing and properties of poly (ε-caprolactone)/carbon nanofibre composite mats and films obtained by electrospinning and solvent casting. J Mater Sci 44:4789–4795. https://doi.org/10.1007/s10853-009-3721-3

ASTM E96/E96M-10 (2010) Standard test methods for water vapor transmission of materials, ASTM International, West Conshohocken. www.astm.org

Carneiro-da-Cunha MG, Cerqueira MA, Souza BWS et al (2010) Physical and thermal properties of a chitosan/alginate nanolayered PET film. Carbohydr Polym 82:153–159. https://doi.org/10.1016/j.carbpol.2010.04.043

Cerqueira MA, Fabra MJ, Castro-Mayorga JL et al (2016) Use of electrospinning to develop antimicrobial biodegradable multilayer systems: encapsulation of cinnamaldehyde and their physicochemical characterization. Food Bioprocess Technol 9:1874–1884. https://doi.org/10.1007/s11947-016-1772-4

Ciolacu D, Ciolacu F, Popa VI (2011) Amorphous cellulose—structure and characterization. Cellul Chem Technol 45:13–21. https://doi.org/10.1163/156856198X00740

Costa MJ, Ramos PE, Fuciños P, Teixeira JA, Pastrana LM, Cerqueira MA (2018) Development of bio-based nanostructured systems by electrohydrodynamic processes. In: Rai VR, Bai JA (eds) Nanotechnology applications in the food industry. CRC Press, Boca Raton, pp 3–20

Crabbe-Mann M, Tsaoulidis D, Parhizkar M, Edirisinghe M (2018) Ethyl cellulose, cellulose acetate and carboxymethyl cellulose microstructures prepared using electrohydrodynamics and green solvents. Cellulose 25:1687–1703. https://doi.org/10.1007/s10570-018-1673-y

Curto JMR, Conceição ELT, Portugal ATG, Simões RMS (2011) Three dimensional modelling of fibrous materials and experimental validation. Materwiss Werksttech 42:370–374. https://doi.org/10.1002/mawe.201100790

Démuth B, Farkas A, Pataki H et al (2016) Detailed stability investigation of amorphous solid dispersions prepared by single-needle and high speed electrospinning. Int J Pharm 498:234–244. https://doi.org/10.1016/j.ijpharm.2015.12.029

Erben J, Pilarova K, Sanetrnik F et al (2015) The combination of meltblown and electrospinning for bone tissue engineering. Mater Lett 143:172–176. https://doi.org/10.1016/j.matlet.2014.12.100

Erbil HY, Demirel AL, AVci Y, Mert O (2003) Transformation of a simple plastic into a superhydrophobic surface. Science 299:1377–1380. https://doi.org/10.1126/science.1078365

Fabra MJ, López-Rubio A, Lagaron JM (2016) Use of the electrohydrodynamic process to develop active/bioactive bi-layer films for food packaging applications. Food Hydrocoll 55:11–18. https://doi.org/10.1016/j.foodhyd.2015.10.026

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Guo A, Liu J, Wang Y, Xu H (2012) Preparation of porous lamellar mullite ceramics with whisker skeletons by electrospinning and pressure molding. Mater Lett 74:107–110. https://doi.org/10.1016/j.matlet.2012.01.080

Han J, Salmieri S, Le Tien C, Lacroix M (2010) Improvement of water barrier property of paperboard by coating application with biodegradable polymers. J Agric Food Chem 58:3125–3131. https://doi.org/10.1021/jf904443n

Hong X, Mahalingam S, Edirisinghe M (2017) Simultaneous application of pressure-infusion-gyration to generate polymeric nanofibers. Macromol Mater Eng 302:1–16. https://doi.org/10.1002/mame.201600564

Huang F, Wei Q, Cai Y, Wu N (2008) Surface structures and contact angles of electrospun poly(vinylidene fluoride) nanofiber membranes. Int J Polym Anal Charact 13:292–301. https://doi.org/10.1080/10236660802190963

Jiang L, Zhao Y, Zhai J (2004) A lotus-leaf-like superhydrophobic surface: a porous microsphere/nanofiber composite film prepared by electrohydrodynamics. Angew Chemie Int Ed 43:4338–4341. https://doi.org/10.1002/anie.200460333

Kasaai MR, Moosavi A (2017) Treatment of Kraft paper with citrus wastes for food packaging applications: water and oxygen barrier properties improvement. Food Packag Shelf Life 12:59–65. https://doi.org/10.1016/j.fpsl.2017.02.006

Khwaldia K, Arab-Tehrany E, Desobry S (2010) Biopolymer coatings on paper packaging materials. Compr Rev Food Sci Food Saf 9:82–91. https://doi.org/10.1111/j.1541-4337.2009.00095.x

Lavoine N, Guillard V, Desloges I et al (2016) Active bio-based food-packaging: diffusion and release of active substances through and from cellulose nanofiber coating toward food-packaging design. Carbohydr Polym 149:40–50. https://doi.org/10.1016/j.carbpol.2016.04.048

Li XY, Zheng ZB, Yu DG et al (2017) Electrosprayed sperical ethylcellulose nanoparticles for an improved sustained-release profile of anticancer drug. Cellulose 24:5551–5564. https://doi.org/10.1007/s10570-017-1498-0

Liakos IL, Holban AM, Carzino R et al (2017) Electrospun fiber pads of cellulose acetate and essential oils with antimicrobial activity. Nanomaterials 7:84. https://doi.org/10.3390/nano7040084

Ma M, Mao Y, Gupta M et al (2005) Superhydrophobic fibers produced by electrospinning and chemical vapor deposition. Macromolecules 38:9742–9748. https://doi.org/10.1021/ma0511189

Marsh K, Bugusu B (2007) Food packaging—roles, materials, and environmental issues: scientific status summary. J Food Sci 72(3):R39–R55. https://doi.org/10.1111/j.1750-3841.2007.00301.x

Matharu RK, Porwal H, Ciric L, Edirisinghe M (2018a) The effect of graphene–poly(methyl methacrylate) fibres on microbial growth. Interface Focus 8:20170058. https://doi.org/10.1098/rsfs.2017.0058

Matharu RK, Charani Z, Ciric L et al (2018b) Antimicrobial activity of tellurium-loaded polymeric fiber meshes. J Appl Polym Sci 135:46368. https://doi.org/10.1002/app.46368

Miyauchi Y, Ding B, Shiratori S (2006) Fabrication of a silver-ragwort-leaf-like super-hydrophobic micro/nanoporous fibrous mat surface by electrospinning. Nanotechnology 17:5151–5156. https://doi.org/10.1088/0957-4484/17/20/019

Nagy ZK, Balogh A, Démuth B et al (2015) High speed electrospinning for scaled-up production of amorphous solid dispersion of itraconazole. Int J Pharm 480:137–142. https://doi.org/10.1016/j.ijpharm.2015.01.025

Parris N, Vergano PJ, Dickey LC et al (1998) Enzymatic hydrolysis of zein—wax-coated paper. J Agric Food Chem 46:4056–4059. https://doi.org/10.1021/jf980406j

PlasticsEurope (2015) Plastics—the facts 2014/2015: an analysis of European plastics production, demand and waste data. PlasticsEurope. https://doi.org/10.1016/j.marpolbul.2013.01.015

Poletto M, Ornaghi Júnior HL, Zattera AJ (2014) Native cellulose: structure, characterization and thermal properties. Materials (Basel) 7:6105–6119. https://doi.org/10.3390/ma7096105

Rhim JW, Lee JH, Hong SI (2007) Increase in water resistance of paperboard by coating with poly(lactide). Packag Technol Sci 20:393–402. https://doi.org/10.1002/pts.767

Robertson GL (2013) Paper and Paper-Based Packaging Materials. In: Robertson GL (ed) Food packaging: principles and practice, 3rd edn. CRC Press, Boca Raton, pp 167–187

Sanla-Ead N, Jangchud A, Chonhenchob V, Suppakul P (2012) Antimicrobial activity of cinnamaldehyde and eugenol and their activity after incorporation into cellulose-based packaging films. Packag Technol Sci 25:7–17. https://doi.org/10.1002/pts.952

Shang HM, Wang Y, Takahashi K et al (2005) Nanostructured superhydrophobic surfaces. J Mater Sci 40:3587–3591. https://doi.org/10.1007/s10853-005-2892-9

Vogler EA (1998) Structure and reactivity of water at biomaterial surfaces. Adv Colloid Interface Sci 74:69–117. https://doi.org/10.1016/S0001-8686(97)00040-7

Wang Q, Yu DG, Zhang LL et al (2017) Electrospun hypromellose-based hydrophilic composites for rapid dissolution of poorly water-soluble drug. Carbohydr Polym 174:617–625. https://doi.org/10.1016/j.carbpol.2017.06.075

WHO (2015) WHO estimates of the global burden of foodborne diseases. WHO. https://doi.org/10.1016/j.fm.2014.07.009

Xu Y, Li JJ, Yu DG et al (2017) Influence of the drug distribution in electrospun gliadin fibers on drug-release behavior. Eur J Pharm Sci 106:422–430. https://doi.org/10.1016/j.ejps.2017.06.017

Yu DG, Li XY, Wang X et al (2015) Nanofibers fabricated using triaxial electrospinning as zero order drug delivery systems. ACS Appl Mater Interfaces 7:18891–18897. https://doi.org/10.1021/acsami.5b06007

Zhang X, Shi F, Niu J et al (2008) Superhydrophobic surfaces: from structural control to functional application. J Mater Chem 18:621–633. https://doi.org/10.1039/B711226B

Zhou Y, Sun T, Chan M et al (2005) Scalable encapsulation of hepatocytes by electrostatic spraying. J Biotechnol 117:99–109. https://doi.org/10.1016/j.jbiotec.2004.11.004

Acknowledgments

This work was supported by Norte Regional Operational Program 2014–2020 (Norte2020) through the European Regional Development Fund (ERDF) Nanotechnology based functional solutions (NORTE-01-0145-FEDER-000019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martins, V.D.F., Cerqueira, M.A., Fuciños, P. et al. Active bi-layer cellulose-based films: development and characterization. Cellulose 25, 6361–6375 (2018). https://doi.org/10.1007/s10570-018-2021-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2021-y