Abstract

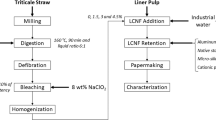

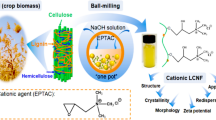

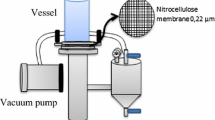

The processing of recycled paper into packaging materials is becoming one of the most important activities of paper mills. However, the use of recycled paper as a raw material causes an important increase of dissolved colloidal substances in industrial waters, known as anionic trash, which greatly increases water conductivity and cationic demand disturbing the function of commonly used retention agents (cationic starch, cationic polyacrylamides). On the other hand, several investigators showed that lignocellulosic nanofibers (LCNF) can be used as reinforcement in papermaking, but their retention can be affected by anionic trash. This work aims to study the technical viability of the application of triticale straw lignocellulose nanofibers in recycled fiber suspensions at industrial scale. For this purpose, a complex retention system of LCNF was proposed to improve the reinforcement efficiency of LCNF. Results show that, with the addition of only 1.5% (w/w) of LCNF, it is possible to fulfill the physical–mechanical requirements of the commercial test liner, and the addition of 4.5% of LCNF would allow the reduction of basis weight and additives or the development of applications with higher mechanical requirements.

Similar content being viewed by others

References

Afra E, Yousefi H, Hadilam MM, Nishino T (2013) Comparative effect of mechanical beating and nanofibrillation of cellulose on paper properties made from bagasse and softwood pulps. Carbohydr Polym 97(2):725–730. https://doi.org/10.1016/j.carbpol.2013.05.032

Bledzki AK, Gassan J (1996) Important properties of colloidal silica in microparticulate systems. Nord Pulp Pap Res J 11(1):15–21

Boufi S, Gandini A (2015) Triticale crop residue: a cheap material for high performance nanofibrillated cellulose. RSC Adv 5(5):3141–3151. https://doi.org/10.1039/C4RA12918K

Boufi S, González I, Delgado-aguilar M, Tarrés Q, Pèlach MÀ, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process : A review. Carbohydr Polym 154:151–166

Carrasco F, Mutje P, Pelach MA (1998) Control of retention in paper-making by colloid titration and zeta potential techniques. Wood Sci Technol 32(2):145–155

Delgado-Aguilar M, González I, Pèlach MA, De La Fuente E, Negro C, Mutjé P (2015a) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22(1):789–802. https://doi.org/10.1007/s10570-014-0473-2

Delgado-aguilar M, González I, Tarrés Q, Alcalà M, Pèlach MÀ (2015b) Approaching a low-cost production of cellulose nanofibers for papermaking applications. BioResourses 10(3):5345–5355

Delgado-Aguilar M, Tarrés Q, Puig J, Boufi S, Blanco A, Mutjé P (2015c) Enzymatic refining and cellulose nanofiber addition in papermaking processes from recycled and deinked slurries. BioResources 10(3):5730–5743

Delgado-Aguilar M, González I, Tarrés Q, Pèlach MA, Alcalà M, Mutjé P (2016) The key role of lignin in the production of low-cost lignocellulosic nanofibers for papermaking applications. Ind Crops Prod 86:295–300. https://doi.org/10.1016/j.indcrop.2016.04.010

Desharnais L, Chabot B, Daneault C, Montplaisir D, Croteau L (2002) Thermomechanical pulp washing effect of retention and drainage. Pulp Pap Can 103(4):44–48

Dunham AJ, Sherman LM, Alfano JC (2002) Effect of dissolved and colloidal substances on drainage properties of mechanical pulp suspensions. J Pulp Pap Sci 28(9):298–304

Espinosa E, Tarrés Q, Delgado-Aguilar M, González I, Mutjé P, Rodríguez A (2016) Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibres and their application to papermaking slurries. Cellulose. https://doi.org/10.1007/s10570-015-0807-8

Fernandes Diniz J, Gil MH, Castro JAAM (2004) Hornification—its origin and interpretation in wood pulps. Wood Sci Technol 37:489–494. https://doi.org/10.1007/s00226-003-0216-2

Garver TM, Xie T, Boegh KH (1997) Variation of white water composition in a TMP and DIP newsprint paper machine. Tappi J 80(8):163–173

Gill RIS (1996) Chemical control of deposits: scopes and limitations. Pap Technol 37(6):23–31

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7(4):5167–5180

Hietala M, Ämmälä A, Silvennoinen J, Liimatainen H (2015) Fluting medium strengthened by periodate–chlorite oxidized nanofibrillated celluloses. Cellul. https://doi.org/10.1007/s10570-015-0801-1

Hubbe MA (2014) Prospects for maintaining strength of paper and paperboard products while using less forest resources: A review. BioResources 9(1):1634–1763

Hubbe MA, Venditti RA, Rojas OJ (2007) What happens to cellulosic fibers during papermaking and recycling? A Review. BioResourse 2:739–788

Hubbe MA, Sundberg A, Mocchiutti P, Ni Y, Pelton R (2012) Dissolved and colloidal substances (dcs) and the charge demand of papermaking process waters and suspensions: a review. BioResources 7(4):6109–6193

Hurter RW (2002a) Nonwood fiber content papers-Part1: Corrugating medium physical properties. HurterConsult

Hurter RW (2002b) Nonwood fiber content papers-Part2: Unbleached papers physical properties. HurterConsult

ISO (1990) ISO 187:1990: Paper, board and pulps—Standard atmosphere for conditioning and testing and procedure for monitoring the atmosphere and conditioning of samples

ISO (1999) ISO 5267-1:1999: Pulps—Determination of drainability—Part 1: Schopper-riegler method

ISO. (2008a). ISO 1924-2:2008: Paper and board—Determination of tensile properties—Part 2: constant rate of elongation method (20 mm/min)

ISO (2008b) ISO 5269-2:2004 Pulps—Preparation of laboratory sheets for physical testing—Part 2: Rapid-Köthen method

ISO. (2011). ISO 534:2011: Paper and board—Determination of thickness, density and specific volume

ISO. (2012). ISO 1974:2012: Paper—Determination tearing resistance—Elmendorf method

ISO. (2013). ISO 5636-5:2013: Paper and board—Determination of air permeance (medium range)—Part 5: Gurley method

ISO. (2014). ISO 2758:2014: Paper—Determination of bursting strength

Korhonen MH, Laine J (2014) Flocculation and retention of fillers with nanoceluloses. Nord Pulp Pap Res J 29(1):119–128

Lourenço AF, Gamelas JAF, Nunes T, Amaral J, Mutjé P, Ferreira PJ (2017) Influence of TEMPO-oxidised cellulose nanofibrils on the properties of filler-containing papers. Cellulose 24(1):349–362. https://doi.org/10.1007/s10570-016-1121-9

Miao Q, Huang L, Chen L (2013) Advances in the control of dissolved and colloidal substances present in papermaking processes: a brief review. BioResources 8(1):1431–1455

Neimo L (1999) Papermaking Chemistry. In: Gullichsen J, Paulapuro H (eds). Jyväskylä: Fapet Oy

Pöyry (2011) Average papermaking fibre furnish the world 1990–2025. Pulp and RP Consumption 1995–2025, World Fibre Outlook, Pöyry LLC

Rouger J, Mutje P (1984) Correlation between the cellulose fibres beating and the fixation of a soluble cationic polymer. Br Polym J 16(2):83–86

Salmi J (2009) Surface interactions in polyelectrolyte-cellulose systems and their implications for flocculation mechanisms. Helsinki University of Technology, TKK

Sehaqui H, Zhou Q, Berglund LA (2013) Nanofibrillated cellulose for enhancement of strength in high-density paper structures. Nord Pulp Pap Res J 28(2):182–189. https://doi.org/10.3183/NPPRJ-2013-28-

Shetty CS, Greer CS, Laubach GD (1994) A likely mechanism for pitch deposition control. Tappi J 77(10):91–96

Swerin A, Ödberg L (1996) Flocculation of cellulosic fibre suspensions by a microparticulate retention aid system consisting of cationic polyacrylamide and anionic montmotillonite. Nord Pulp Pap Res J 11(1):22–27

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17(5):1005–1020. https://doi.org/10.1007/s10570-010-9431-9

TAPPI (2014) T569 om-14: internal bond strength (Scott type)

Tarrés Q, Saguer E, Pèlach MA, Alcalà M, Delgado-Aguilar M, Mutjé P (2016) The feasibility of incorporating cellulose micro/nanofibers in papermaking processes: the relevance of enzymatic hydrolysis. Cellulose. https://doi.org/10.1007/s10570-016-0889-y

Tarrés Q, Ehman NV, Evangelina M, Area MC, Delgado-aguilar M, Mutjé P (2017) Lignocellulosic nanofibers from triticale straw: the influence of hemicelluloses and lignin in their production and properties. Carbohyd Polym 163:20–27. https://doi.org/10.1016/j.carbpol.2017.01.017

Wang Y, Ni J, Chen C, Peng J, Liu H (2014) Anionic trash control in high-yield pulp (HYP) containing furnish by using a poly-DADMAC based commercial formulation. J Ind Eng Chem 20(6):4452–4456. https://doi.org/10.1016/j.jiec.2014.02.016

Whipple WL, Maltesh C (2002) Adsorption of cationic flocculants to paper slurries. J Colloid Interface Sci 256(1):33–40. https://doi.org/10.1006/jcis.2001.7867

Zhang X, Beatson RP, Cai YJ, Saddler JN (1999) Accumulation of specific dissolved and colloidal substances during white water recycling affects paper properties. J Pulp Pap Sci 25(6):206–210

Acknowledgments

The authors wish to acknowledge the financial support of the Economy and Competitiveness Ministry of the Spanish Government by the project CTQ2013–48090–C2–2–R.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tarrés, Q., Area, M.C., Vallejos, M.E. et al. Key role of anionic trash catching system on the efficiency of lignocellulose nanofibers in industrial recycled slurries. Cellulose 25, 357–366 (2018). https://doi.org/10.1007/s10570-017-1589-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1589-y