Abstract

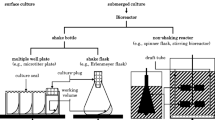

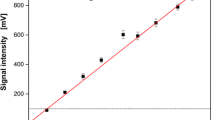

Dissolved oxygen plays an essential role in aerobic cultivation especially due to its low solubility. Under unfavorable conditions of mixing and vessel geometry it can become limiting. This, however, is difficult to predict and thus the right choice for an optimal experimental set-up is challenging. To overcome this, we developed a method which allows a robust prediction of the dissolved oxygen concentration during aerobic growth. This integrates newly established mathematical correlations for the determination of the volumetric gas–liquid mass transfer coefficient (kLa) in disposable shake-flasks from the filling volume, the vessel size and the agitation speed. Tested for the industrial production organism Corynebacterium glutamicum, this enabled a reliable design of culture conditions and allowed to predict the maximum possible cell concentration without oxygen limitation.

Similar content being viewed by others

Abbreviations

- µ:

-

Specific growth rate (h−1)

- c:

-

Oxygen concentration (mmol l−1; %)

- c* :

-

Saturated oxygen concentration (c* = 0.232 mmol l−1 at 30 °C; c* = 0.212 mmol l−1 at 37 °C For relative expression, c* was set to 100 %) (mmol l−1; %)

- kLa:

-

Gas–liquid mass transfer coefficient (h−1)

- n:

-

Shaking frequency (h−1)

- OTR:

-

Oxygen transfer rate (mmol h−1)

- OUR:

-

Oxygen uptake rate (mmol h−1)

- \( {\text{q}}_{{{\text{O}}_{2} }} \) :

-

Specific oxygen uptake rate (mmol g−1CDW h−1)

- Vmax :

-

Maximum flask volume (ml)

- X:

-

Biomass concentration (g l−1)

- Gaussian fitting:

-

a, b, c, x0, y0

- Parabolic fitting:

-

a, b, c, d, y0

References

Becker J, Wittmann C (2012) Bio-based production of chemicals, materials and fuels—Corynebacterium glutamicum as versatile cell factory. Curr Opin Biotechnol 23:631–640

Becker J, Klopprogge C, Schröder H, Wittmann C (2009) Metabolic engineering of the tricarboxylic acid cycle for improved lysine production by Corynebacterium glutamicum. Appl Microbiol Biotechnol 75:7866–7869

Becker J, Buschke N, Bücker R, Wittmann C (2010) Systems level engineering of Corynebacterium glutamicum—reprogramming translational efficiency for superior production. Eng Life Sci 10:430–438

Büchs J (2001) Introduction to advantages and problems of shaken cultures. Biochem Eng J 7:91–98

Eduardo GSC, Aurora MT, Guillermo AO (2012) Oxygen transfer coefficient and the kinetic parameters of exo-polygalacturonase production by Aspergillus flavipes FP-500 in shake-flasks and bioreactor. Lett Appl Microbiol. doi:10.1111/j.1472-765X.2012.03313.x

Eibl R, Kaiser S, Lombriser R, Eibl D (2010) Disposable bioreactors: the current state-of-the-art and recommended applications in biotechnology. Appl Microbiol Biotechnol 86:41–49

Garcia-Ochoa F, Gomez E, Santos VE, Merchuk JC (2010) Oxygen uptake rate in microbial processes: an overview. Biochem Eng J 49:289–307

Ge X, Rao G (2012) Real-time monitoring of shake-flask fermentation and off gas using triple disposable noninvasive optical sensors. Biotechnol Prog 28:872–877

Hermann R, Walther N, Maier U, Büchs J (2001) Optical method for the determination of the oxygen-transfer capacity of small bioreactors based on sulfite oxidation. Biotechnol Bioeng 74:355–363

John GT, Klimant I, Wittmann C, Heinzle E (2003) Integrated optical sensing of dissolved oxygen in microtiter plates: a novel tool for microbial cultivation. Biotechnol Bioeng 81:829–836

López JLC, Rodríguez Porcel EM, Oller Alberola I, Ballesteros Martin MM, Sánchez Pérez JA, Fernández Sevilla JM, Chisti Y (2006) Simultaneous determination of oxygen consumption rate and volumetric oxygen transfer coefficient in pneumatically agitated bioreactors. Ind Eng Chem Res 45(3):1167–1171

Nicolas P, Mäder U, Dervyn E, Rochat T, Leduc A, Pigeonneau N et al (2012) Condition-dependent transcriptome reveals high-level regulatory architecture in Bacillus subtilis. Science 335:1103–1106

Ries C, John G, John C, Eibl R, Eibl D (2010) A shaken disposable bioreactor system for controlled insect cell cultivations at milliliter-scale. Eng Life Sci 10:75–79

Schneider K, Schütz V, John GT, Heinzle E (2010) Optical device for parallel online measurement of dissolved oxygen and pH in shake-flask cultures. Bioprocess Biosyst Eng 33:541–547

Seletzky JM, Noak U, Fricke J, Welk E, Eberhard W, Knocke C, Büchs J (2007) Scale-up from shake-flasks to fermenters in batch and continuous mode with Corynebacterium glutamicum on lactic acid based on oxygen transfer and pH. Biotechnol Bioeng 98:800–811

Thongchuang M, Pongsawasdi P, Chisti Y, Packdibamrung K (2012) Design of a recombinant Escherichia coli for producing l-phenylalanine from glycerol. World J Microbiol Biotechnol 28:2937–2943

Tsai W-L, Autsen JL, Ma J, Hudson T, Luo J (2012) Noninvasive optical sensor technology in shake-flasks. Bioprocess Int 1:50–56

Tunac JB (1989) High-aeration capacity shake-flask system. J Ferment Bioeng 68:157–159

Veglio F, Beolchinia F, Ubaldinib S (1998) Empirical models for oxygen mass transfer: a comparison between shake-flask and lab-scale fermentor and application to manganiferous ore bioleaching. Process Biochem 33:367–376

Vickers CE, Klein-Marcuschamer D, Krömer JO (2012) Examining the feasibility of bulk commodity production in Escherichia coli. Biotechnol Lett 34:585–596

Wittmann C, Kim HM, John G, Heinzle E (2003) Characterization and application of an optical sensor for quantification of dissolved O2 in shake-flasks. Biotechnol Lett 25:377–380

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Schiefelbein, S., Fröhlich, A., John, G.T. et al. Oxygen supply in disposable shake-flasks: prediction of oxygen transfer rate, oxygen saturation and maximum cell concentration during aerobic growth. Biotechnol Lett 35, 1223–1230 (2013). https://doi.org/10.1007/s10529-013-1203-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-013-1203-9