Abstract

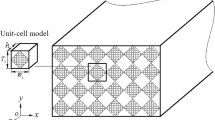

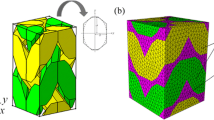

A study is conducted with the aim of developing multi-scale analytical method for designing the composite helicopter arm with three-dimensional (3D) five-directional braided structure. Based on the analysis of 3D braided microstructure, the multi-scale finite element modeling is developed. Finite element analysis on the load capacity of 3D five-directional braided composites helicopter arm is carried out using the software ABAQUS/Standard. The influences of the braiding angle and loading condition on the stress and strain distribution of the helicopter arm are simulated. The results show that the proposed multi-scale method is capable of accurately predicting the mechanical properties of 3D braided composites, validated by the comparison the stress-strain curves of meso-scale RVCs. Furthermore, it is found that the braiding angle is an important factor affecting the mechanical properties of 3D five-directional braided composite helicopter arm. Based on the optimized structure parameters, the nearly net-shaped composite helicopter arm is fabricated using a novel resin transfer mould (RTM) process.

Similar content being viewed by others

References

Ko, F.K., Pastore, C.M.: Structure and properties of an integrated three dimensional fabric for structural composites. In: Vinson JR and Taya M (eds) Recent advances in composites in the United States and Japan, ASTM STP 864. Philadelphia, PA:ASTM, p. 428–439 (1985)

Chen, L., Tao, X.M., Choy, C.L.: Mechanical analysis of 3-D braided composites by the finite multiphase element method. Compos. Sci. Technol. 59(16), 2383–2391 (1999)

Mouritz, A.P., Bannister, M.K., Falzon, P.J., Leong, K.H.: Review of applications for advanced three-dimensional fibre textile composites. Compos. Part. A-App. S. 30(12), 1445–1461 (1999)

Bassam, E.S., Dmitry, I., Andrew, C.L., Stephen, R.H.: Multi-scale modelling of strongly heterogenerous 3D composite structures using spatial Voronoi tessellation. J. Mech. Phy. Solids. 88, 50–71 (2016)

Vanaershot, A., Cox, B.N., Lomov, S.V., Vandepitte, D.: Stochastic multi-scale modelling of textile composites based on internal geometry variability. Comput. Struct. 122, 55–64 (2013)

Chamis, C.C.: Mechanics of composite mateirals: past, present and future. J. Comp. Technol. Res. 11, 3–14 (1989)

Christensen, R.M., Lo, K.H.: Solutions for effective shear properties in three phase shere and cylinder models. J. Mech. Phys. Solids. 27, 315–330 (1979)

Fang, G.D., Liang, J., Lu, Q., Wang, B.L., Wang, Y.: Investigation on the compressive properties of the three dimensional four-directional braided composites. Compos. Struct. 93, 392–405 (2011)

Fang, G.D., Liang, J., Wang, Y., Wang, B.L.: The effect of yarn distortion on the mechanical properties of 3D four-directional braided composites. Compos. Part. A-App. S. 40, 343–350 (2009)

Lu, Z.X., Wang, C.Y., Xia, B., Yang, Z.Y.: Effect of interfacial properties on the uniaxial tensile behavior of three-dimensional braided composites. Comp. Mater. Sci. 79, 547–557 (2013)

Caner, F.C., Bazant, Z.P., Hoover, C.G., Waas, A.M., Shahwan, K.W.: Microplane Model for Fracturing Damage of Triaxially Braided Fiber-Polymer Composites. J. Eng Mater-T. Asme. 13(2), (2011)

Zhang, Y., Jiang, L.L., Sun, B., Gu, B.H.: Transverse impact behaviors of four-step 3-D rectangular braided composites from unit-cell approach. J. Reinf. Plast. Comp. 31(4), 233–246 (2012)

Wu, L.W., Sun, B.X., Gu, B.H.: Numerical analyses of bending fatigue of four-step three-dimensional rectangular-braided composite materials from unit cell approach. J Text I. 106(1), 67–79 (2015)

Zhang, D.T., Sun, Y., Wang, X.M., Chen, L.: Prediction of macro-mechanical properties of 3D braided composites based on fiber embedded matrix method. Compos. Struct. 134, 393–408 (2015)

Zhang, C., Binienda, W.K.: A meso-scale finite element model for simulating free-edge effect of carbon/epoxy textile composite. Mech. Mater. 76, 1–19 (2014)

Li, J.C., Chen, L., Zhang, Y.F., Ning, P.: Microstructure and finite element analysis of 3D five-directional braided composites. J. Reinf. Plast. Comp. 31, 107–115 (2012)

Wang, X.Y., Tang, Y.Z.: Mechanical analysis and designing of composite materials. National defense science and technology univesity press, Changsha, (1999, In Chinese)

Budiansky, B., Fleck, N.: Compressive failure of fiber composites. J. Mech. Phy. Solids. 41, 183–211 (1993)

Lomov, S., Ivanov, D., Verpoest, I., Zako, M., Kurashiki, T., Nakai, H., Hirosawa, S.: Meso-FE modeling of textile composites: road map, data flow and algorithms. Compos. Sci. Technol. 67(9), 1870–1891 (2007)

Stover, E., Mark, W., Marfowitz, I., Mueller, W.: Preparation of an omniweave reinforced carbon-carbon cylinder as a candidate for evaluation in the adavaced head shield screening program. USA: AFML-TR-70-283 (1971)

Florenitine, R.: Apparatus for weaving a three-dimensional article. US Patent 4312261 (1982)

Li, J.C., Zhang, Y.F., Sun, F., Chen, L.: Mechanics analysis of three-dimensional five-directional braided composites I: microstructural model. Acta. Mater. Compos. Sinica. 26(1), 150–155 (2009)

Reifsnider, K.: Some fundamental aspects of the fatigue and fracture response of composite mateirals. In: Proceedings of the 14th Annual Meeting, USA, 373–384 (1977)

Hashin, Z.: Failure criteria for unidirectional fiber composite. J. Appl. Mech. 47, 329–334 (1980)

Cordebois, J., Sidoroff, F.: Anisotropic damage in elasticity and plasticity. Journal. de. mecanique. theorique. et. appliquee. 45–59 (1980)

Segurado, J., Llorca, J.: A numerical approximation to the elastic properties of sphere-reinforced composites. Journal. Mech. Phys. Solids. 50, 2107–2121 (2002)

Zhang, C., Xu, X.: Application of three unit-cells models on mechanical analysis of 3D five-directional and full five-directional braided composites. Appl. Compos. Mater. 20(5), 803–825 (2013)

Kalidindi, S.R., Abusafieh, A.: Longitudinal and transverse moduli and strengths of low angle 3-D braided composites. J. Compos. Mater. 30(8), 885–905 (1996)

Acknowledgments

This work was supported by the National Key Research and Development Program of China (No. 2016YFC-0304301) and Scientific and Technological Transformative Project of Jiangsu Province (No.BA2016170).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Chen, L., Sun, Y. et al. Multi-Scale Modeling of an Integrated 3D Braided Composite with Applications to Helicopter Arm. Appl Compos Mater 24, 1233–1250 (2017). https://doi.org/10.1007/s10443-017-9584-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9584-x