Abstract

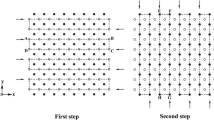

In this paper, a new multi-unit cell model of three dimensionally braided composites is presented on the basis of the microstructure analysis of 3D braided preforms produced by four-step 1 × 1 method. According to a new unit cell partition scheme, the multi-unit cell model possesses five kinds of unit cells, namely interior, exterior surface, interior surface, exterior corner and interior corner unit cells. Each type of the representative volume cell has unique microstructure and volume fraction in braided composites. On the basis of these five unit cell models, the structural geometry parameters of the preforms are analyzed and the relationship between the structural parameters and the braiding parameters in different regions are derived in detail, such as the braiding angles, fiber volume fraction, yarn packing factor, braiding pitch and so on. Finally, by using the multi-unit cell model, the main structural parameters of braided composites specimens are calculated to validate the effectiveness of the model. The results are in good agreement with the available experimental data. In addition, the effect of braiding angle on the squeezing condition of braiding yarn is analyzed. The variations of the volume proportion of five unit cells to the whole specimen with rows and columns are discussed, respectively. The presented multi-unit cell model can be adopted to design 3D braided composites and predict their mechanical properties.

Similar content being viewed by others

References

Ko F.K.: Three-dimensional fabrics for composites: An introduction to the magnaweave structure. In: Proceedings of the 4th International Conference on Composite Material (ICCM-4), Tokyo/Japan, p. 1609-1678 (1982)

Yang, J.M., Ma, C.L., Chou, T.W.: Fiber inclination model of three dimensional textile structural composites. J. Compos. Mater. 20(5), 472–484 (1986)

Li, W., Hammad, M., El-Shiekh, A.: Structure analysis of 3-D braided preforms for composites. J. Text. Inst. 81(4), 491–514 (1990)

Lei, C., Cai, Y.J., Ko, F.K.: Finite element analysis of 3-D braided composite. Adv. Eng. Softw. 14(3), 187–194 (1992)

Kostar, T.D., Chou, T.W.: Design and automated fabrication of 3D braided preforms for advanced structural composites. In: computer aided design in composite material technology III, pp. 63–78. Elsevier, Amsterdam (1992)

Wang, Y.Q., Wang, A.S.D.: Microstructure/property relationships in three-dimensionally braided fiber composites. Compos. Sci. Technol. 53(2), 213–232 (1995)

Byun, J.H., Chou, T.W.: Process-microstructure relationships of 2-step and 4-step braided composites. Compos. Sci. Technol. 56(3), 235–251 (1996)

Chen, L., Tao, X.M., Choy, C.L.: On the microstructure of three-dimensional braided performs. Compos. Sci. Technol. 59(3), 391–404 (1999)

Sun, X.K., Sun, C.J.: Mechanical properties of three-dimensional braided composites. Compos. Struct. 65(3–4), 485–492 (2004)

Chen, L., Tao, X.M., Choy, C.L.: Mechanical analysis of 3-D braided composites by the finite multiphase element method. Compos. Sci. Technol. 59(16), 2383–2391 (1999)

Tang, Z.X., Postle, R.: Mechanics of three-dimensional braided structures for composite materials- partII: prediction of the elastic moduli. Compos. Struct. 51(4), 451–457 (2001)

Yu, X.G., Cui, J.Z.: The prediction on mechanical properties of 4-step braided composites via two-scale method. Compos. Sci. Technol. 67(3–4), 471–480 (2007)

Fang, G.D., Lang, J., Wang, Y., Wang, B.L., Fang, G.D., Lang, J., Wang, Y., Wang, B.L.: The effect of yarn distortion on the mechanical properties of 3D four-directional braided composites. Compos. Part A 40(4), 343–350 (2009)

Li, D.S., Fang, D.N., Lu, Z.X., et al.: Finite element analysis of mechanical properties of 3D four directional rectangular braided composites, Part1: microgeometry and 3D finite element model. Appl. Compos. Mater. 17(4), 389–404 (2010)

Shokrieh, M., Mazloomi, M.: A new analytical model for calculation of stiffness of three-dimensional four directional braided composites. Compos. Struct. 94(3), 1005–1015 (2012)

Vanaerschot, A., Cox, B.N., Lomov, S.V., et al.: Stochastic multi-scale modelling of textile composites based on internal geometry variability. Comput. Struct. 122, 55–64 (2013)

Blacklock, M., Bale, H., Begley, M., Cox, B.: Generating virtual textile composite specimens using statistical data from micro-computed tomography: 1D tow representations for the Binary Model. J. Mech. Phys. Solids. 60, 451–470 (2012)

Rinaldi, R., Blacklock, M., Bale, H., et al.: Generating virtual textile composite specimens using statistical data from micro-computed tomography: 3D tow representations. J. Mech. Phys. Solids. 60, 1561–1581 (2012)

Chen, L., Li, J.L., Li, X.M., et al.: Yarn architecture of 3D rectangular braided preforms. Acta. Mater. Compos. Sin. 17(3), 1–5 (2000)

Acknowledgments

The author wish to acknowledge the support received from the National Natural Science Foundation of China (Grant No. 11302045) and the Fundamental Research Funds for the Central Universities (Grant No. ZYGX2011J122).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, K., Qian, X. Microstructure Analysis and Multi-Unit Cell Model of Three Dimensionally Four-Directional Braided Composites. Appl Compos Mater 22, 29–50 (2015). https://doi.org/10.1007/s10443-014-9396-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-014-9396-1