Abstract

In this paper, the corner spring-in angles of AS4/8552 L-shaped composite profiles with different thicknesses are predicted using path-dependent constitutive law with the consideration of material properties variation due to phase change during curing. The prediction accuracy mainly depends on the properties in the rubbery and glassy states obtained by homogenization method rather than experimental measurements. Both analytical and finite element (FE) homogenization methods are applied to predict the overall properties of AS4/8552 composite. The effect of fiber volume fraction on the properties is investigated for both rubbery and glassy states using both methods. And the predicted results are compared with experimental measurements for the glassy state. Good agreement is achieved between the predicted results and available experimental data, showing the reliability of the homogenization method. Furthermore, the corner spring-in angles of L-shaped composite profiles are measured experimentally and the reliability of path-dependent constitutive law is validated as well as the properties prediction by FE homogenization method.

Similar content being viewed by others

References

Joven, R., Tavakol, B., Rodriguez, A., Guzman, M., Minaie, B.: Characterization of shear stress at the tool-part interface during autoclave processing of prepreg composites. J. Appl. Polym. Sci. 129(4), 2017–2028 (2013)

Roozbehjavan, P., Tavakol, B., Ahmed, A., Koushyar, H., Das, R., Joven, R., Minaie, B.: Experimental and numerical study of distortion in flat, L-shaped, and U-shaped carbon fiber–epoxy composite parts. J. Appl. Polym. Sci. 131(13), n/a-n/a (2014)

Mezeix, L., Seman, A., Nasir, M.N.M., Aminanda, Y., Rivai, A., Castanié, B., Olivier, P., Ali, K.M.: Spring-back simulation of unidirectional carbon/epoxy flat laminate composite manufactured through autoclave process. Compos. Struct. 124, 196–205 (2015)

Kappel, E., Stefaniak, D., Fernlund, G.: Predicting process-induced distortions in composite manufacturing – a pheno-numerical simulation strategy. Compos. Struct. 120, 98–106 (2015)

Bapanapalli, S.K., Smith, L.V.: A linear finite element model to predict processing-induced distortion in FRP laminates. Compos. A: Appl. Sci. Manuf. 36(12), 1666–1674 (2005)

Radford, D.W., Rennick, T.S.: Separating sources of manufacturing distortion in laminated composites. J. Reinf. Plast. Compos. 19(8), 621–641 (2000)

Arafath, A.R.A., Vaziri, R., Poursartip, A.: Closed-form solution for process-induced stresses and deformation of a composite part cured on a solid tool: part I – flat geometries. Compos. A: Appl. Sci. Manuf. 39(7), 1106–1117 (2008)

Arafath, A.R.A., Vaziri, R., Poursartip, A.: Closed-form solution for process-induced stresses and deformation of a composite part cured on a solid tool: part II – curved geometries. Compos. A: Appl. Sci. Manuf. 40(10), 1545–1557 (2009)

Kappel, E., Stefaniak, D., Holzhüter, D., Hühne, C., Sinapius, M.: Manufacturing distortions of a CFRP box-structure – a semi-numerical prediction approach. Compos. A: Appl. Sci. Manuf. 51, 89–98 (2013)

Bogetti, T.A., Gillespie, J.W.: Process-induced stress and deformation in thick-section thermoset composite laminates. J. Compos. Mater. 26(5), 626–660 (1992)

Kim, Y.K., White, S.R.: Process-induced stress relaxation analysis of AS4/3501-6 laminate. J. Reinf. Plast. Compos. 16(1), 2–16 (1997)

Johnston, A. A.: An integrated model of the development of process-induced deformation in autoclave processing of composite structures. Ph.D., The University of British Columbia (Canada) (1998)

Baran, I., Tutum, C.C., Nielsen, M.W., Hattel, J.H.: Process induced residual stresses and distortions in pultrusion. Compos. Part B 51, 148–161 (2013)

Magnus Svanberg, J., Anders Holmberg, J.: Prediction of shape distortions part I. FE-implementation of a path dependent constitutive model. Compos. A: Appl. Sci. Manuf. 35(6), 711–721 (2004)

Baran, I., Akkerman, R., Hattel, J.H.: Modelling the pultrusion process of an industrial L-shaped composite profile. Compos. Struct. 118, 37–48 (2014)

Baran, I., Hattel, J.H., Akkerman, R.: Investigation of process induced warpage for pultrusion of a rectangular hollow profile. Compos. Part B 68, 365–374 (2015)

Ding, A., Li, S., Wang, J., Zu, L.: A three-dimensional thermo-viscoelastic analysis of process-induced residual stress in composite laminates. Compos. Struct. 129, 60–69 (2015)

Baran, I., Hattel, J., Akkerman, R., Tutum, C.: Mechanical modelling of pultrusion process: 2D and 3D numerical approaches. Appl. Compos. Mater. 22(1), 99–118 (2015)

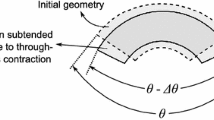

Ersoy, N., Garstka, T., Potter, K., Wisnom, M.R., Porter, D., Stringer, G.: Modelling of the spring-in phenomenon in curved parts made of a thermosetting composite. Compos. A: Appl. Sci. Manuf. 41(3), 410–418 (2010)

Çınar, K., Öztürk, U.E., Ersoy, N., Wisnom, M.R.: Modelling manufacturing deformations in corner sections made of composite materials. J. Compos. Mater. 48(7), 799–813 (2014)

Svanberg, J., Altkvist, C., Nyman, T.: Prediction of shape distortions for a curved composite C-spar. J. Reinf. Plast. Compos. 24(3), 323–339 (2005)

Hubert, P.: Aspects of flow and compaction of laminated composite shapes during cure. Text, (1996)

Sorrentino, L., Bellini, C.: Compaction influence on spring-in of thin composite parts: experimental and numerical results. J. Compos. Mater. 49(17), 2149–2158 (2015)

Chen, J., Hallett, S., Wisnom, M.R.: Modelling complex geometry using solid finite element meshes with correct composite material orientations. Comput. Struct. 88(9–10), 602–609 (2010)

Darrow, D.A., Smith, L.V.: Isolating components of processing induced warpage in laminated composites. J. Compos. Mater. 36(21), 2407–2419 (2002)

Johnston, A., Vaziri, R., Poursartip, A.: A plane strain model for process-induced deformation of laminated composite structures. J. Compos. Mater. 35(16), 1435–1469 (2001)

Garstka, T., Ersoy, N., Potter, K.D., Wisnom, M.R.: In situ measurements of through-the-thickness strains during processing of AS4/8552 composite. Compos. A: Appl. Sci. Manuf. 38(12), 2517–2526 (2007)

Ersoy, N., Garstka, T., Potter, K., Wisnom, M.R., Porter, D., Clegg, M., Stringer, G.: Development of the properties of a carbon fibre reinforced thermosetting composite through cure. Compos. A: Appl. Sci. Manuf. 41(3), 401–409 (2010)

Ersoy, N., Potter, K., Wisnom, M.R., Clegg, M.J.: An experimental method to study the frictional processes during composites manufacturing. Compos. A: Appl. Sci. Manuf. 36(11), 1536–1544 (2005)

Ersoy, N., Potter, K., Wisnom, M.R., Clegg, M.J.: Development of spring-in angle during cure of a thermosetting composite. Compos. A: Appl. Sci. Manuf. 36(12), 1700–1706 (2005)

Luciano, R., Barbero, E.J.: Formulas for the stiffness of composites with periodic microstructure. Int. J. Solids Struct. 31(21), 2933–2944 (1994)

Ramm, E., Rank, E., Rannacher, R., Schweizerhof, K., Stein, E., Wendland, W., Wittum, G., Wriggers, P., Wunderlich, W.: Error-controlled adaptive finite elements in solid mechanics. John Wiley & Sons (2003)

Barbero, E. J.: Finite element analysis of composite materials using AbaqusTM. CRC press (2013)

Fernlund, G., Rahman, N., Courdji, R., Bresslauer, M., Poursartip, A., Willden, K., Nelson, K.: Experimental and numerical study of the effect of cure cycle, tool surface, geometry, and lay-up on the dimensional fidelity of autoclave-processed composite parts. Compos. A: Appl. Sci. Manuf. 33(3), 341–351 (2002)

Kappel, E., Stefaniak, D., Hühne, C.: Process distortions in prepreg manufacturing – an experimental study on CFRP L-profiles. Compos. Struct. 106, 615–625 (2013)

Sorrentino, L., Polini, W., Bellini, C.: To design the cure process of thick composite parts: experimental and numerical results. Adv. Compos. Mater. 23(3), 225–238 (2014)

Sorrentino, L., Bellini, C.: In-process monitoring of cure degree by coplanar plate sensors. Int. J. Adv. Manuf. Technol. 1–9 (2016)

Kappel, E.: Forced-interaction and spring-in – relevant initiators of process-induced distortions in composite manufacturing. Compos. Struct. 140, 217–229 (2016)

Abdelal, G., Robotham, A., Cantwell, W.: Autoclave cure simulation of composite structures applying implicit and explicit FE techniques. Int. J. Mech. Mater. Des. 9(1), 55–63 (2013)

Zhu, Q., Geubelle, P.H., Li, M., Tucker, C.L.: Dimensional accuracy of thermoset composites: simulation of process-induced residual stresses. J. Compos. Mater. 35(24), 2171–2205 (2001)

Twigg, G., Poursartip, A., Fernlund, G.: Tool–part interaction in composites processing. Part I: experimental investigation and analytical model. Compos. A: Appl. Sci. Manuf. 35(1), 121–133 (2004)

Acknowledgments

This work reported here was part of the Fundamental Research Funds for the Central Universities supported by Wuhan University of Technology.

Author information

Authors and Affiliations

Corresponding authors

Appendix

Appendix

The AS4 fiber mechanical properties are assumed to be transversely in the SCM. Thus five independent elastic constants for fiber are present, including Young’s modulus and the Poisson’s ratio in the transverse direction (E 22f and ν 23f ), Young’s modulus and the Poisson’s ratio in the longitudinal direction (E 11f and ν 12f ) and the shear modulus in the longitudinal direction (G 12f ). The SCM proposed by Bogetti and Gillesoie [10] are given as follows:

where k f k r and k T are the isotropic plane strain bulk modulus for fiber, resin and composite materials, respectively. They can be defined by:

Rights and permissions

About this article

Cite this article

Ding, A., Li, S., Wang, J. et al. Prediction of Process-Induced Distortions in L-Shaped Composite Profiles Using Path-Dependent Constitutive Law. Appl Compos Mater 23, 1027–1045 (2016). https://doi.org/10.1007/s10443-016-9501-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-016-9501-8