Abstract

3D-printing technologies such as electron beam melting (EBM) have allowed for patient-specific orthopaedic implants, however differences generated from the fabrication process may alter the corrosion properties of Ti6Al4V implants. This study evaluated the corrosion characteristics of EBM-fabricated Ti6Al4V, alongside any linked microstructural and surface changes. EBM-fabricated Ti6Al4V and wrought Ti6Al4V specimens (n = 10 per group) underwent microstructural and surface characterisation before and after corrosion testing. Cyclic potentiodynamic polarisation of specimens was conducted in accordance with ASTM Standard F2129-17. The degree of corrosion damage was subsequently assessed via qualitative and quantitative measures. EBM-fabricated Ti6Al4V demonstrated a higher proportion of β phases and greater surface roughness, compared to wrought Ti6Al4V. Significant differences were observed for all corrosion parameters between the two groups. The lower breakdown potentials (Eb) for EBM-fabricated Ti6Al4V (2.035 V), compared to wrought Ti6Al4V (3.667 V), indicate a lower resistance to pitting corrosion. A greater resultant spread, and severity of corrosion damage was noted on wrought Ti6Al4V. An inferior in vitro corrosion resistance was observed for EBM-fabricated Ti6Al4V. Without post-processing, the rougher surface and differences in microstructure are likely to contribute to this. This suggests potential clinical implications upon in vivo implantation, although corrosion measures remain above recommended minimums.

Similar content being viewed by others

References

Abdeen, D. H., and B. R. Palmer. Corrosion evaluation of Ti-6Al-4V parts produced with electron beam melting machine. Rapid Prototyp. J. 22(2):322–329, 2016.

Abdeen, D. H., and B. R. Palmer. Effect of processing parameters of electron beam melting machine on properties of Ti-6Al-4V parts. Rapid Prototyp. J. 22(3):609–620, 2016.

Aksakal, B., Ö. Yildirim, and H. Gul. Metallurgical failure analysis of various implant materials used in orthopedic applications. J. Fail. Anal. Prev. 4(3):17–23, 2004.

Al-Bermani, S. S., M. L. Blackmore, W. Zhang, and I. Todd. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. 41A(13):3422–3434, 2010.

Arcam. In: Ti6Al4V: Titanium Alloy, edited by Arcam. Sweden: Mölndal.

Arcam. In: Arcam A1: The future in implant manufacturing, edited by Arcam. Sweden: Mölndal.

ASTM. G15-07: Standard Terminology Relating to Corrosion and Corrosion Testing. West Conshohocken: ASTM International, 2007.

ASTM. F1472-14: Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications. West Conshohocken: ASTM International, 2014.

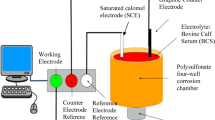

ASTM. F2129-17: Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptibility of Small Implant Devices. West Conshohocken: ASTM International, 2017.

Atwood, S. A., E. W. Patten, K. J. Bozic, L. A. Pruitt, and M. D. Ries. Corrosion-induced fracture of a double-modular hip prosthesis: a case report. J. Bone Joint Surg. Am. 92(6):1522–1525, 2010.

Atwood, S. A., E. W. Patten, K. J. Bozic, L. A. Pruitt, and M. D. Ries. Corrosion-induced fracture of a double-modular hip prosthesis: a case report. JBJS 92(6):1522–1525, 2010.

Bai, Y., X. Gai, S. Li, L.-C. Zhang, Y. Liu, Y. Hao, et al. Improved corrosion behaviour of electron beam melted Ti-6Al-4V alloy in phosphate buffered saline. Corros. Sci. 123:289–296, 2017.

Brooks, E. K., R. P. Brooks, and M. T. Ehrensberger. Effects of simulated inflammation on the corrosion of 316L stainless steel. Mater. Sci. Eng. C. 71(Supplement C):200–205, 2017.

Chen, J.-R., and W.-T. Tsai. In situ corrosion monitoring of Ti–6Al–4V alloy in H2SO4/HCl mixed solution using electrochemical AFM. Electrochim. Acta 56(4):1746–1751, 2011.

Dai, N., L.-C. Zhang, J. Zhang, Q. Chen, and M. Wu. Corrosion behavior of selective laser melted Ti-6Al-4V alloy in NaCl solution. Corros. Sci. 102:484–489, 2016.

de Damborenea, J. J., M. A. Arenas, M. A. Larosa, A. L. Jardini, C. A. de Carvalho Zavaglia, and A. Conde. Corrosion of Ti6Al4V pins produced by direct metal laser sintering. Appl. Surf. Sci. 393:340–347, 2017.

Devika, D., S. S. Dass, and S. K. Chaudhary. Characterization and corrosion behaviour study on biocompatible Ti-6Al-4V component fabricated by Electron Beam Melting. J. Biomim. Biomater. Biomed. Eng. 22:63–75, 2015.

Dimitriou, D., M. H. L. Liow, T.-Y. Tsai, W. A. Leone, G. Li, and Y.-M. Kwon. Early outcomes of revision surgery for taper corrosion of dual taper total hip arthroplasty in 187 patients. J. Arthroplasty 31(7):1549–1554, 2016.

Gammon, L. M., R. D. Briggs, J. M. Packard, K. W. Batson, R. Boyer, and C. W. Domby. Metallography and Microstructures of Titanium and Its Alloys. Materials Park: ASM International, pp. 899–917, 2004.

Goldberg, J. R., J. L. Gilbert, J. J. Jacobs, T. W. Bauer, W. Paprosky, and S. Leurgans. A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin. Orthop. Relat. Res. 401:149–161, 2002.

Gurappa, I. Characterization of different materials for corrosion resistance under simulated body fluid conditions. Mater. Charact. 49(1):73–79, 2002.

Hiemenz, J. Electron beam melting. Adv. Mater. Process. 165(3):45–46, 2007.

Hoang, D., D. Perrault, M. Stevanovic, and A. Ghiassi. Surgical applications of three-dimensional printing: a review of the current literature & how to get started. Ann. Transl. Med. 4(23):456, 2016.

Hsu, A. R., J. D. Kim, D. Fabi, and B. R. Levine. Adverse reactions in metal-on-metal total hip arthroplasty: two cases presenting as pseudoseptic acetabular component loosening. Am. J. Orthop. 40(10):509, 2011.

Iebba, M., A. Astarita, D. Mistretta, I. Colonna, M. Liberini, F. Scherillo, et al. Influence of powder characteristics on formation of porosity in additive manufacturing of Ti-6Al-4V components. J. Mater. Eng. Perform. 26(8):4138–4147, 2017.

ISO. Biological Evaluation of Medical Devices. Part 15: Identification and Quantification of Degradation Products from Metals and Alloys. Geneva: International Organization for Standardization, 2000.

Kherrouba, N., M. Bouabdallah, R. Badji, D. Carron, and M. Amir. Beta to alpha transformation kinetics and microstructure of Ti-6Al-4V alloy during continuous cooling. Mater. Chem. Phys. 181(Supplement C):462–469, 2016.

Koike, M., K. Martinez, L. Guo, G. Chahine, R. Kovacevic, and T. Okabe. Evaluation of titanium alloy fabricated using electron beam melting system for dental applications. J. Mater. Process. Technol. 211(8):1400–1408, 2011.

Loeber, L., S. Biamino, U. Ackelid, S. Sabbadini, P. Epicoco, and P. Fino, et al., editors. Comparison of selective laser and electron beam melted titanium aluminides. Proceedings of the Solid Freeform Fabrication Symposium, Austin, 2011

Lonn, M. K., J. M. Metcalf, and B. D. Choules. In vivo and in vitro nitinol corrosion properties. Shape Mem. Superelast. 1(3):328–338, 2015.

Moayed, M. H., N. J. Laycock, and R. C. Newman. Dependence of the critical pitting temperature on surface roughness. Corros. Sci. 45(6):1203–1216, 2003.

Mok, S. W., R. Nizak, S. C. Fu, K. W. K. Ho, L. Qin, D. B. F. Saris, et al. From the printer: potential of three-dimensional printing for orthopaedic applications. J. Orthop. Transl. 6:42–49, 2016.

Munir, S., and W. R. Walsh. The quantification of corrosion damage for pre-stressed conditions: a model using stainless steel. J. Bio- Tribo-Corros. 2(1):4, 2016.

Murr, L. E., E. V. Esquivel, S. A. Quinones, S. M. Gaytan, M. I. Lopez, E. Y. Martinez, et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti–6Al–4V biomedical prototypes compared to wrought Ti–6Al–4V. Mater. Charact. 60(2):96–105, 2009.

Murr, L. E., S. M. Gaytan, E. Martinez, F. Medina, and R. B. Wicker. Next generation orthopaedic implants by additive manufacturing using electron beam melting. Int. J. Biomater. 2012:14, 2012.

Nava-Dino, C., C. López-Meléndez, R. Bautista-Margulis, M. Neri-Flores, J. Chacón-Nava, S. de la Torre, et al. Corrosion behavior of Ti-6Al-4V alloys. Int. J. Electrochem. Sci. 7:2389–2402, 2012.

Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 243(1):231–236, 1998.

Parthasarathy, J., B. Starly, S. Raman, and A. Christensen. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 3(3):249–259, 2010.

Puebla, K., L. E. Murr, S. M. Gaytan, E. Martinez, F. Medina, and R. B. Wicker. Effect of melt scan rate on microstructure and macrostructure for electron beam melting of Ti-6Al-4V. Mater. Sci. Appl. 3(5):6, 2012.

Puleo, D. A., and A. Nanci. Understanding and controlling the bone–implant interface. Biomaterials 20(23):2311–2321, 1999.

Rosenbloom, S. N., and R. A. Corbett. An assessment of ASTM F 2129 electrochemical testing of small medical implants—lessons learned. CORROSION, 2007.

Safdar, A., H. Z. He, L. Y. Wei, A. Snis, and L. E. Chavez De Paz. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 18(5):401–408, 2012.

Safdar, A., L. Y. Wei, A. Snis, and Z. Lai. Evaluation of microstructural development in electron beam melted Ti-6Al-4V. Mater. Charact. 65(Supplement C):8–15, 2012.

Skendzel, J. G., J. D. Blaha, and A. G. Urquhart. Total hip arthroplasty modular neck failure. J. Arthroplasty 26(2):338.e1–338.e4, 2011.

Sullivan, S. J. L., D. Madamba, S. Sivan, K. Miyashiro, M. L. Dreher, C. Trépanier, et al. The effects of surface processing on in vivo corrosion of Nitinol stents in a porcine model. Acta Biomater. 62:385–396, 2017.

Textor, M., C. Sittig, V. Frauchiger, S. Tosatti, and D. M. Brunette. Properties and Biological Significance of Natural Oxide Films on Titanium and Its Alloys. Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications. Berlin: Springer, pp. 171–230, 2001.

Tower, S. S. Arthroprosthetic cobaltism: neurological and cardiac manifestations in two patients with metal-on-metal arthroplasty: a case report. J. Bone Joint Surg. Am. 92(17):2847–2851, 2010.

Urban, R. M., M. J. Tomlinson, D. J. Hall, and J. J. Jacobs. Accumulation in liver and spleen of metal particles generated at nonbearing surfaces in hip arthroplasty. J. Arthroplasty 19(8):94–101, 2004.

Vrancken, B., L. Thijs, J.-P. Kruth, and J. Van Humbeeck. Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties. J. Alloys Compd. 541(Supplement C):177–185, 2012.

Vu, N. B., N. H. Truong, L. T. Dang, L. T. Phi, N. T.-T. Ho, T. N. Pham, et al. In vitro and in vivo biocompatibility of Ti-6Al-4V titanium alloy and UHMWPE polymer for total hip replacement. Biomed. Res. Therapy. 3(3):567–577, 2016.

Watters, T. S., W. C. Eward, R. K. Hallows, L. G. Dodd, S. S. Wellman, and M. P. Bolognesi. Pseudotumor with superimposed periprosthetic infection following metal-on-metal total hip arthroplasty: a case report. J. Bone Joint Surg. Am. 92(7):1666–1669, 2010.

Weiser, M. C., and D. D. Chen. Revision for taper corrosion at the neck-body junction following total hip arthroplasty: pearls and pitfalls. Curr. Rev. Musculoskelet. Med. 9(1):75–83, 2016.

Wilcox, B., R. J. Mobbs, A.-M. Wu, and K. Phan. Systematic review of 3D printing in spinal surgery: the current state of play. J. Spine Surg. 3(3):433–443, 2017.

Willert, H.-G., G. H. Buchhorn, A. Fayyazi, R. Flury, M. Windler, G. Köster, et al. Metal-on-metal bearings and hypersensitivity in patients with artificial hip joints: a clinical and histomorphological study. JBJS. 87(1):28–36, 2005.

Wright, G., S. Sporer, R. Urban, and J. Jacobs. Fracture of a modular femoral neck after total hip arthroplasty: a case report. J. Bone Joint Surg. Am. 92(6):1518–1521, 2010.

Xu, Y., K. L. Sundberg, and R. D. Sisson. Corrosion behavior of Ti6Al4V fabricated by direct metal laser sintering. Proceedings of the 13th World Conference on Titanium. New York: Wiley, 2016, pp. 1501–1505.

Xu, N., F. Wei, X. Liu, L. Jiang, H. Cai, Z. Li, et al. Reconstruction of the upper cervical spine using a personalized 3D-printed vertebral body in an adolescent with ewing sarcoma. Spine (Phila Pa 1976) 41(1):E50–E54, 2016.

Yang, J., H. Yang, H. Yu, Z. Wang, and X. Zeng. Corrosion behavior of additive manufactured Ti-6Al-4V alloy in NaCl solution. Metall. Mater. Trans. A 48(7):3583–3593, 2017.

Zhao, X., S. Li, M. Zhang, Y. Liu, T. B. Sercombe, S. Wang, et al. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 95(Supplement C):21–31, 2016.

Zhao, B., H. Wang, N. Qiao, C. Wang, and M. Hu. Corrosion resistance characteristics of a Ti-6Al-4V alloy scaffold that is fabricated by electron beam melting and selective laser melting for implantation in vivo. Mater. Sci. Eng. C 70:832–841, 2017.

Acknowledgments

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Associate Editor Andreas Anayiotos oversaw the review of this article.

Rights and permissions

About this article

Cite this article

Mah, D., Pelletier, M.H., Lovric, V. et al. Corrosion of 3D-Printed Orthopaedic Implant Materials. Ann Biomed Eng 47, 162–173 (2019). https://doi.org/10.1007/s10439-018-02111-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10439-018-02111-1