Abstract

Current constitutive theories face challenges when predicting the extremely large deformation and fracture of hydrogels, which calls for the demands to reveal the fundamental mechanism of the various mechanical behaviors of hydrogels from bottom up. Proper hydrogel network model provides a better approach to bridge the gap between the micro-structure and the macroscopic mechanical responses. This work summarizes the theoretical and numerical researches on the hydrogel network models, aiming to provide new insights into the effect of microstructure on the swelling-deswelling process, hyperelasticity, viscoelasticity and fracture of hydrogels. Hydrogel network models are divided into full-atom network models, realistic network models and abstract network models. Full-atom network models have detailed atomic structure but small size. Realistic network models with different coarse-graining degree have large model size to explain the swelling-deswelling process, hyperelasticity and viscoelasticity. Abstract network models abstract polymer chains into analytical interactions, leading to the great leap of model size. It shows advantages to reproduce the crack initiation and propagation in hydrogels by simulating chain scission. Further research directions on the network modeling are suggested. We hope this work can help integrate the merits of network modeling methods and continuum mechanics to capture the various mechanical behaviors of hydrogels.

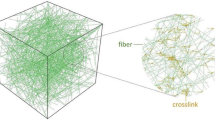

Graphic abstract

The random polymer network structure determines the macroscopic mechanical behaviors of hydrogels. This work summarizes the theoretical and numerical researches on the hydrogel network models. Full-atom network models depict the fundamental configurations of hydrogel network in atomic scale. Realistic network models based on different coarse-grain strategies have large model size. Abstract network models with much larger size are capable to not only bridge the underlying mechanism in microscale or mesoscale with the mechanical response in macroscale, but also integrate the merits of discrete methods and continuum mechanics.

Reproduced from Ref [118]. with permission

Reproduced from Ref. [74] with permission

Reproduced from Ref. [89] with permission

Reproduced from Ref. [115]. with permission (1 bar = 1 × 105 Pa, 1 ps = 1 × 10–12 s)

reproduced from Ref. [74] with permission

Reproduced from Ref [96]. with permission

Reproduced from Ref. [96] with permission

Similar content being viewed by others

References

Zheng, Z., Bian, S., Li, Z., et al.: Catechol modified quaternized chitosan enhanced wet adhesive and antibacterial properties of injectable thermo-sensitive hydrogel for wound healing. Carbohydr. Polym. 249, 116826 (2020). https://doi.org/10.1016/j.carbpol.2020.116826

Chen, T., Liu, H., Dong, C., et al.: Synthesis and characterization of temperature/pH dual sensitive hemicellulose-based hydrogels from eucalyptus APMP waste liquor. Carbohydr. Polym. 247, 116717 (2020). https://doi.org/10.1016/j.carbpol.2020.116717

Xian, S., Webber, M.J.: Temperature-responsive supramolecular hydrogels. J. Mater. Chem. B 8, 9197–9211 (2020). https://doi.org/10.1039/d0tb01814g

Nourian, A.H., Amiri, A., Moini, N., et al.: Synthesis, test, calibration and modeling of a temperature-actuated hydrogel bilayer. Smart Mater. Struct. 29, 105001 (2020). https://doi.org/10.1088/1361-665X/ab9f46

Sun, X.-C., Xia, H., Xu, X.-L., et al.: Ingenious humidity-powered micro-worm with asymmetric biped from single hydrogel. Sens. Actuators B 322, 128620 (2020). https://doi.org/10.1016/j.snb.2020.128620

Zhang, J., Huang, C., Chen, Y., et al.: Polyvinyl alcohol: a high-resolution hydrogel resist for humidity-sensitive micro-/nanostructure. Nanotechnology 31, 425303 (2020). https://doi.org/10.1088/1361-6528/ab9da7

Bian, C., Cheng, Y., Zhu, W., et al.: A novel optical fiber Mach-Zehnder interferometer based on the calcium alginate hydrogel film for humidity sensing. IEEE Sens. J. 20, 5759–5765 (2020). https://doi.org/10.1109/jsen.2020.2973290

Jang, J., Kang, K., Raeis-Hosseini, N., et al.: Self-powered humidity sensor using chitosan-based plasmonic metal-hydrogel-metal filters. Adv. Opt. Mater. 8, 1901932 (2020). https://doi.org/10.1002/adom.201901932

Chen, X., Li, H., Lam, K.Y.: A multiphysics model of photo-sensitive hydrogels in response to light-thermo-pH-salt coupled stimuli for biomedical applications. Bioelectrochemistry 135, 107584 (2020). https://doi.org/10.1016/j.bioelechem.2020.107584

Xing, J., Yang, B., Dang, W., et al.: Preparation of photo/electro-sensitive hydrogel and its adsorption/desorption behavior to acid Fuchsine. Water Air Soil Pollut. 231, 231 (2020). https://doi.org/10.1007/s11270-020-04582-2

Shuai, S., Zhou, S., Liu, Y., et al.: The preparation and property of photo- and thermo-responsive hydrogels with a blending system. J. Mater. Sci. 55, 786–795 (2020). https://doi.org/10.1007/s10853-019-04010-9

Li, P., Zhang, J., Dong, C.-M.: Photosensitive poly(o-nitrobenzyloxycarbonyl-L-lysine)-b-PEO polypeptide copolymers: synthesis, multiple self-assembly behaviors, and the photo/pH-thermo-sensitive hydrogels. Polym. Chem. 8, 7033–7043 (2017). https://doi.org/10.1039/c7py01574g

Shang, J., Theato, P.: Smart composite hydrogel with pH-, ionic strength- and temperature-induced actuation. Soft Matter 14, 8401–8407 (2018). https://doi.org/10.1039/c8sm01728j

Li, W., Jiang, C., Lu, S., et al.: A hydrogel microsphere-based sensor for dual and highly selective detection of Al3+ and Hg2+. Sens. Actuators B 321, 128490 (2020). https://doi.org/10.1016/j.snb.2020.128490

Liao, J., Huang, H.: Smart pH/magnetic sensitive Hericium erinaceus residue carboxymethyl chitin/Fe3O4 nanocomposite hydrogels with adjustable characteristics. Carbohydr. Polym. 246, 116644 (2020). https://doi.org/10.1016/j.carbpol.2020.116644

Ata, S., Rasool, A., Islam, A., et al.: Loading of Cefixime to pH sensitive chitosan based hydrogel and investigation of controlled release kinetics. Int. J. Biol. Macromol. 155, 1236–1244 (2020). https://doi.org/10.1016/j.ijbiomac.2019.11.091

Liu, T.-Y., Hu, S.-H., Liu, K.-H., et al.: Study on controlled drug permeation of magnetic-sensitive ferrogels: effect of Fe3O4 and PVA. J. Control. Release 126, 228–236 (2008). https://doi.org/10.1016/j.jconrel.2007.12.006

Liu, T.-Y., Hu, S.-H., Liu, T.-Y., et al.: Magnetic-sensitive behavior of intelligent ferrogels for controlled release of drug. Langmuir 22, 5974–5978 (2006). https://doi.org/10.1021/la060371e

Awasthi, S., Gaur, J.K., Bobji, M.S.: Advanced ferrogels with high magnetic response and wear resistance using carbon nanotubes. J. Alloy. Compd. 848, 156259 (2020). https://doi.org/10.1016/j.jallcom.2020.156259

Bhattarai, N., Gunn, J., Zhang, M.: Chitosan-based hydrogels for controlled, localized drug delivery. Adv. Drug Deliv. Rev. 62, 83–99 (2010). https://doi.org/10.1016/j.addr.2009.07.019

Li, J., Mooney, D.J.: Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 1, 16071 (2016). https://doi.org/10.1038/natrevmats.2016.71

Hamedi, H., Moradi, S., Hudson, S.M., et al.: Chitosan based hydrogels and their applications for drug delivery in wound dressings: a review. Carbohydr. Polym. 199, 445–460 (2018). https://doi.org/10.1016/j.carbpol.2018.06.114

Merino, S., Martin, C., Kostarelos, K., et al.: Nanocomposite hydrogels: 3D polymer-nanoparticle synergies for on-demand drug delivery. ACS Nano 9, 4686–4697 (2015). https://doi.org/10.1021/acsnano.5b01433

Chen, C.H., Tsai, C.C., Chen, W.S., et al.: Novel living cell sheet harvest system composed of thermoreversible methylcellulose hydrogels. Biomacromol 7, 736–743 (2006). https://doi.org/10.1021/bm0506400

Cushing, M.C., Anseth, K.S.: Hydrogel cell cultures. Science 316, 1133–1134 (2007). https://doi.org/10.1126/science.1140171

Liebmann, T., Rydholm, S., Akpe, V., et al.: Self-assembling Fmoc dipeptide hydrogel for in situ 3D cell culturing. BMC Biotechnol. 7, 88 (2007). https://doi.org/10.1186/1472-6750-7-88

Shinohara, S., Kihara, T., Sakai, S., et al.: Fabrication of in vitro three-dimensional multilayered blood vessel model using human endothelial and smooth muscle cells and high-strength PEG hydrogel. J. Biosci. Bioeng. 116, 231–234 (2013). https://doi.org/10.1016/j.jbiosc.2013.02.013

Yuk, H., Varela, C.E., Nabzdyk, C.S., et al.: Dry double-sided tape for adhesion of wet tissues and devices. Nature 575, 169–174 (2019). https://doi.org/10.1038/s41586-019-1710-5

Censi, R., Di Martino, P., Vermonden, T., et al.: Hydrogels for protein delivery in tissue engineering. J. Control. Release 161, 680–692 (2012). https://doi.org/10.1016/j.jconrel.2012.03.002

Dimatteo, R., Darling, N.J., Segura, T.: In situ forming injectable hydrogels for drug delivery and wound repair. Adv. Drug Deliv. Rev. 127, 167–184 (2018). https://doi.org/10.1016/j.addr.2018.03.007

Wang, R., Li, J., Chen, W., et al.: A biomimetic mussel-inspired epsilon-poly-L-lysine hydrogel with robust tissue-anchor and anti-infection capacity. Adv. Func. Mater. 27, 1604894 (2017). https://doi.org/10.1002/adfm.201604894

Liu, L., Li, X., Ren, X., et al.: Flexible strain sensors with rapid self-healing by multiple hydrogen bonds. Polymer 202, 122657 (2020). https://doi.org/10.1016/j.polymer.2020.122657

Tian, K., Bae, J., Bakarich, S.E., et al.: 3D printing of transparent and conductive heterogeneous hydrogel-elastomer systems. Adv. Mater. 29, 1604827 (2017). https://doi.org/10.1002/adma.201604827

Huang, Y., Zhong, M., Shi, F., et al.: An intrinsically stretchable and compressible supercapacitor containing a polyacrylamide hydrogel electrolyte. Angew. Chem. Int. Ed. 56, 9141–9145 (2017). https://doi.org/10.1002/anie.201705212

Lin, S., Yuk, H., Zhang, T., et al.: Stretchable hydrogel electronics and devices. Adv. Mater. 28, 4497–4505 (2016). https://doi.org/10.1002/adma.201504152

Zhong, R., Tang, Q., Wang, S., et al.: Self-assembly of enzyme-like nanofibrous G-molecular hydrogel for printed flexible electrochemical sensors. Adv. Mater. 30, 1706887 (2018). https://doi.org/10.1002/adma.201706887

Zhou, Y., Wan, C., Yang, Y., et al.: Highly stretchable, elastic, and ionic conductive hydrogel for artificial soft electronics. Adv. Func. Mater. 29, 1806220 (2019). https://doi.org/10.1002/adfm.201806220

Liao, M., Wan, P., Wen, J., et al.: Wearable, healable, and adhesive epidermal sensors assembled from Mussel-inspired conductive hybrid hydrogel framework. Adv. Func. Mater. 27, 1703852 (2017). https://doi.org/10.1002/adfm.201703852

Ghorbanoghli, A., Narooei, K.: A new hyper-viscoelastic model for investigating rate dependent mechanical behavior of dual cross link self-healing hydrogel. Int. J. Mech. Sci. 159, 278–286 (2019). https://doi.org/10.1016/j.ijmecsci.2019.06.019

Lin, J., Zheng, S.Y., Xiao, R., et al.: Constitutive behaviors of tough physical hydrogels with dynamic metal-coordinated bonds. J. Mech. Phys. Solids 139, 103915 (2020). https://doi.org/10.1016/j.jmps.2020.103935

Caccavo, D., Cascone, S., Lamberti, G., et al.: Hydrogels: experimental characterization and mathematical modelling of their mechanical and diffusive behaviour. Chem. Soc. Rev. 47, 2357–2373 (2018). https://doi.org/10.1039/c7cs00638a

Hu, Y., Suo, Z.: Viscoelasticity and poroelasticity in elastomeric gels. Acta Mech. Solida Sin. 25, 441–458 (2012). https://doi.org/10.1016/s0894-9166(12)60039-1

Hong, W., Liu, Z., Suo, Z.: Inhomogeneous swelling of a gel in equilibrium with a solvent and mechanical load. Int. J. Solids Struct. 46, 3282–3289 (2009). https://doi.org/10.1016/j.ijsolstr.2009.04.022

Hong, W., Zhao, X., Zhou, J., et al.: A theory of coupled diffusion and large deformation in polymeric gels. J. Mech. Phys. Solids 56, 1779–1793 (2008). https://doi.org/10.1016/j.jmps.2007.11.010

Chester, S.A., Anand, L.: A coupled theory of fluid permeation and large deformations for elastomeric materials. J. Mech. Phys. Solids 58, 1879–1906 (2010). https://doi.org/10.1016/j.jmps.2010.07.020

Liu, Y., Zhang, H., Zhang, J., et al.: Constitutive modeling for polymer hydrogels: a new perspective and applications to anisotropic hydrogels in free swelling. Eur. J. Mech. A. Solids 54, 171–186 (2015). https://doi.org/10.1016/j.euromechsol.2015.07.001

Huang, R., Zheng, S., Liu, Z., et al.: Recent advances of the constitutive models of smart materials: hydrogels and shape memory polymers. Int. J. Appl. Mech. 12, 2050014 (2020). https://doi.org/10.1142/s1758825120500143

Xu, S., Liu, Z.: A nonequilibrium thermodynamics approach to the transient properties of hydrogels. J. Mech. Phys. Solids 127, 94–110 (2019)

Chester, S.A., Di Leo, C.V., Anand, L.: A finite element implementation of a coupled diffusion-deformation theory for elastomeric gels. Int. J. Solids Struct. 52, 1–18 (2015). https://doi.org/10.1016/j.ijsolstr.2014.08.015

Mao, Y., Talamini, B., Anand, L.: Rupture of polymers by chain scission. Extreme Mech. Lett. 13, 17–24 (2017). https://doi.org/10.1016/j.eml.2017.01.003

Yang, C., Yin, T., Suo, Z.: Polyacrylamide hydrogels. I. Network imperfection. J. Mech. Phys. Solids 131, 43–55 (2019). https://doi.org/10.1016/j.jmps.2019.06.018

Zhang, E., Bai, R., Morelle, X.P., et al.: Fatigue fracture of nearly elastic hydrogels. Soft Matter 14, 3563–3571 (2018). https://doi.org/10.1039/c8sm00460a

Zhang, W., Hu, J., Tang, J., et al.: Fracture toughness and fatigue threshold of tough hydrogels. ACS Macro Lett. 8, 17–23 (2018). https://doi.org/10.1021/acsmacrolett.8b00788

Bai, R., Yang, Q., Tang, J., et al.: Fatigue fracture of tough hydrogels. Extreme Mech. Lett. 15, 91–96 (2017). https://doi.org/10.1016/j.eml.2017.07.002

Tang, J., Li, J., Vlassak, J.J., et al.: Fatigue fracture of hydrogels. Extreme Mech. Lett. 10, 24–31 (2017). https://doi.org/10.1016/j.eml.2016.09.010

Lavoie, S.R., Millereau, P., Creton, C., et al.: A continuum model for progressive damage in tough multinetwork elastomers. J. Mech. Phys. Solids 125, 523–549 (2019). https://doi.org/10.1016/j.jmps.2019.01.001

Li, B., Bouklas, N.: A variational phase-field model for brittle fracture in polydisperse elastomer networks. Int. J. Solids Struct. 182, 193–204 (2020). https://doi.org/10.1016/j.ijsolstr.2019.08.012

Mao, Y., Anand, L.: A theory for fracture of polymeric gels. J. Mech. Phys. Solids 115, 30–53 (2018). https://doi.org/10.1016/j.jmps.2018.02.008

Lu, X., Hou, Y., Tie, Y., et al.: Crack nucleation and propagation simulation in brittle two-phase perforated/particulate composites by a phase field model. Acta. Mech. Sin. 36, 493–512 (2020). https://doi.org/10.1007/s10409-020-00927-6

Zheng, S., Liu, Z.: The machine learning embedded method of parameters determination in the constitutive models and potential applications for hydrogels. Int. J. Appl. Mech. 13, 2150001 (2021). https://doi.org/10.1142/s1758825121500010

Ghareeb, A., Elbanna, A.: An adaptive quasicontinuum approach for modeling fracture in networked materials: application to modeling of polymer networks. J. Mech. Phys. Solids 137, 103819 (2020). https://doi.org/10.1016/j.jmps.2019.103819

Xu, S., Wang, Y., Hu, J., et al.: Atomic understanding of the swelling and phase transition of polyacrylamide hydrogel. Int. J. Appl. Mech. 8, 1640002 (2016). https://doi.org/10.1142/S1758825116400020

Deshmukh, S., Mooney, D.A., McDermott, T., et al.: Molecular modeling of thermo-responsive hydrogels: observation of lower critical solution temperature. Soft Matter 5, 1514–1521 (2009). https://doi.org/10.1039/b816443f

Sun, T.-Y., Liang, L.-J., Wang, Q., et al.: A molecular dynamics study on pH response of protein adsorbed on peptide-modified polyvinyl alcohol hydrogel. Biomater. Sci. 2, 419–426 (2014). https://doi.org/10.1039/c3bm60213c

Ou, X., Han, Q., Dai, H.-H., et al.: Molecular dynamic simulations of the water absorbency of hydrogels. J. Mol. Model. 21, 231 (2015). https://doi.org/10.1007/s00894-015-2784-0

Jiang, X., Wang, C., Han, Q.: Molecular dynamic simulation on the state of water in poly(vinyl alcohol) hydrogel. Comput. Theoret. Chem. 1102, 15–21 (2017). https://doi.org/10.1016/j.comptc.2016.12.041

Mathesan, S., Rath, A., Ghosh, P.: Molecular mechanisms in deformation of cross-linked hydrogel nanocomposite. Mater. Sci. Eng. C 59, 157–167 (2016). https://doi.org/10.1016/j.msec.2015.09.087

Wang, Y., Li, X., Wei, Q., et al.: Molecular dynamics simulation of mechanical properties for poly(vinyl pyrrolidone)/poly(vinyl alcohol) hydrogel. Asian J. Chem. 26, 5378–5382 (2014). https://doi.org/10.14233/ajchem.2014.18116

Hou, D., Xu, J., Zhang, Y., et al.: Insights into the molecular structure and reinforcement mechanism of the hydrogel-cement nanocomposite: an experimental and molecular dynamics study. Composites B 177, 107421 (2019). https://doi.org/10.1016/j.compositesb.2019.107421

Zhang, H., Wang, H., Xu, G., et al.: A molecular dynamics simulation of N-(fluorenyl-9-methoxycarbonyl)-dipeptides supramolecular hydrogel. Colloids Surf. A 417, 217–223 (2013). https://doi.org/10.1016/j.colsurfa.2012.10.066

Salahshoor, H., Rahbar, N.: Multi-scale mechanical and transport properties of a hydrogel. J. Mech. Behav. Biomed. Mater. 37, 299–306 (2014). https://doi.org/10.1016/j.jmbbm.2014.05.028

Chen, S., Yong, X.: Dissipative particle dynamics modeling of hydrogel swelling by osmotic ensemble method. J. Chem. Phys. 149, 094904 (2018). https://doi.org/10.1063/1.5045100

Wei, Q., Wang, Y., Zhang, Y., et al.: Aggregation behavior of nano-silica in polyvinyl alcohol/polyacrylamide hydrogels based on dissipative particle dynamics. Polymers 9, 611 (2017). https://doi.org/10.3390/polym9110611

Lei, J., Xu, S., Li, Z., et al.: Study on large deformation behavior of polyacrylamide hydrogel using dissipative particle dynamics. Front. Chem. 8, 115 (2020). https://doi.org/10.3389/fchem.2020.00115

Kuhn, W., Grün, F.: Beziehungen zwischen elastischen Konstanten und Dehnungsdoppelbrechung hochelastischer Stoffe. Kolloid-Zeitschrift 101, 248–271 (1942). https://doi.org/10.1007/BF01793684

Dauber-Osguthorpe, P., Roberts, V.A., Osguthorpe, D.J., et al.: Structure and energetics of ligand binding to proteins: Escherichia coli dihydrofolate reductase-trimethoprim, a drug-receptor system. Proteins Struct. Func. Bioinf. 4, 31–47 (1988). https://doi.org/10.1002/prot.340040106

Kaminski, G., Duffy, E.M., Matsui, T., et al.: Free-energies of hydration and pure liquid properties of hydrocarbons from the OPLS all-atom model. J. Phys. Chem. 98, 13077–13082 (1994). https://doi.org/10.1021/j100100a043

Berendsen, H.J.C., Vanderspoel, D., Vandrunen, R.: GROMACS: a message-passing parallel molecular-dynamics implementation. Comput. Phys. Commun. 91, 43–56 (1995). https://doi.org/10.1016/0010-4655(95)00042-e

Mayo, S.L., Olafson, B.D., Goddard, W.A.: Dreiding-a generic force-field for molecular simulations. J. Phys. Chem. 94, 8897–8909 (1990). https://doi.org/10.1021/j100389a010

Wu, Y., Joseph, S., Aluru, N.R.: Effect of cross-linking on the diffusion of water, ions, and small molecules in hydrogels. J. Phys. Chem. B 113, 3512–3520 (2009). https://doi.org/10.1021/jp808145x

Xu, S., Cai, S., Liu, Z.: Thermal conductivity of polyacrylamide hydrogels at the nanoscale. ACS Appl. Mater. Interfaces. 10, 36352–36360 (2018). https://doi.org/10.1021/acsami.8b09891

Marrink, S.J., Risselada, H.J., Yefimov, S., et al.: The MARTINI force field: coarse grained model for biomolecular simulations. J. Phys. Chem. B 111, 7812–7824 (2007). https://doi.org/10.1021/jp071097f

Groot, R.D., Rabone, K.: Mesoscopic simulation of cell membrane damage, morphology change and rupture by nonionic surfactants. Biophys. J . 81, 725–736 (2001). https://doi.org/10.1016/S0006-3495(01)75737-2

Groot, R.D.: Applications of dissipative particle dynamics. Springer, Berlin (2004)

Palkar, V., Choudhury, C.K., Kuksenok, O.: Development of Dissipative Particle Dynamics framework for modeling hydrogels with degradable bonds. MRS Adv. 5, 927–934 (2020). https://doi.org/10.1557/adv.2020.148

Groot, R.D., Warren, P.B.: Dissipative particle dynamics: bridging the gap between atomistic and mesoscopic simulation. J. Chem. Phys. 107, 4423–4435 (1997)

Longo, G.S., de la Cruz, M.O., Szleifer, I.: Molecular theory of weak polyelectrolyte gels: the role of pH and salt concentration. Macromolecules 44, 147–158 (2011). https://doi.org/10.1021/ma102312y

Landsgesell, J., Sean, D., Kreissl, P., et al.: Modeling gel swelling equilibrium in the mean field: from explicit to Poisson-Boltzmann models. Phys. Rev. Lett. 122, 208002 (2019). https://doi.org/10.1103/PhysRevLett.122.208002

Yin, Y., Bertin, N., Wang, Y., et al.: Topological origin of strain induced damage of multi-network elastomers by bond breaking. Extreme Mech. Lett. 40, 100883 (2020). https://doi.org/10.1016/j.eml.2020.100883

Zidek, J., Milchev, A., Vilgis, T.A.: Dynamic behavior of acrylic acid clusters as quasi-mobile nodes in a model of hydrogel network. J. Chem. Phys. 137, 244908 (2012). https://doi.org/10.1063/1.4769833

Zidek, J., Jancar, J., Milchev, A., et al.: Mechanical response of hybrid cross-linked networks to uniaxial deformation: a molecular dynamics model. Macromolecules 47, 8795–8807 (2014). https://doi.org/10.1021/ma501504z

Zidek, J., Milchev, A., Jancar, J., et al.: Deformation-induced damage and recovery in model hydrogels: a molecular dynamics simulation. J. Mech. Phys. Solids 94, 372–387 (2016). https://doi.org/10.1016/j.jmps.2016.05.013

Košovan, P., Richter, T., Holm, C.: Modeling of polyelectrolyte gels in equilibrium with salt solutions. Macromolecules 48, 7698–7708 (2015). https://doi.org/10.1021/acs.macromol.5b01428

Mann, B.A.F., Kremer, K., Lenz, O., et al.: Hydrogels in poor solvents: a molecular dynamics study. Macromol. Theory Simul. 20, 721–734 (2011). https://doi.org/10.1002/mats.201100050

Li, Z., Liu, Z.: Energy transfer speed of polymer network and its scaling-law of elastic modulus-New insights. J. Appl. Phys. 126, 215101 (2019). https://doi.org/10.1063/1.5129621

Li, Z., Liu, Z.: The elongation-criterion for fracture toughness of hydrogels based on percolation model. J. Appl. Phys. 127, 215101 (2020). https://doi.org/10.1063/5.0009626

Wall, F.T.: Statistical thermodynamics of rubber III. J. Chem. Phys. 11, 527–530 (1943). https://doi.org/10.1063/1.1723793

Grest, G.S., Kremer, K.: Molecular-dynamics simulation for polymers in the presence of a heat bath. Phys. Rev. A 33, 3628–3631 (1986). https://doi.org/10.1103/PhysRevA.33.3628

Doi, M. Edwards, S.F., Theory of polymer dynamics. 1986.

Davidson, J.D., Goulbourne, N.C.: A nonaffine network model for elastomers undergoing finite deformations. J. Mech. Phys. Solids 61, 1784–1797 (2013). https://doi.org/10.1016/j.jmps.2013.03.009

Xiang, Y., Zhong, D., Wang, P., et al.: A general constitutive model of soft elastomers. J. Mech. Phys. Solids 117, 110–122 (2018). https://doi.org/10.1016/j.jmps.2018.04.016

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 41, 389–412 (1993). https://doi.org/10.1016/0022-5096(93)90013-6

Ying, L., Tang, S., Kröger, M., et al.: Molecular simulation guided constitutive modeling on finite strain viscoelasticity of elastomers. J. Mech. Phys. Solids 88, 204–226 (2016). https://doi.org/10.1016/j.jmps.2015.12.007

Davidson, J.D., Goulbourne, N.C.: Nonaffine chain and primitive path deformation in crosslinked polymers. Modell. Simul. Mater. Sci. Eng. 24, 065002 (2016). https://doi.org/10.1088/0965-0393/24/6/065002

Zhang, L., Feng, X., Li, S.: Review and perspective on soft matter modeling in cellular mechanobiology: cell contact, adhesion, mechanosensing, and motility. Acta Mech. 228, 4095–4122 (2017). https://doi.org/10.1007/s00707-017-2057-3

Broedersz, C.P., MacKintosh, F.C.: Modeling semiflexible polymer networks. Rev. Mod. Phys. 86, 995–1036 (2014). https://doi.org/10.1103/RevModPhys.86.995

Colombo, J., Widmer-Cooper, A., Del Gado, E.: Microscopic picture of cooperative processes in restructuring gel networks. Phys. Rev. Lett. 110, 198301 (2013). https://doi.org/10.1103/PhysRevLett.110.198301

Alame, G., Brassart, L.: Relative contributions of chain density and topology to the elasticity of two-dimensional polymer networks. Soft Matter 15, 5703–5713 (2019). https://doi.org/10.1039/c9sm00796b

Kothari, K., Hu, Y., Gupta, S., et al.: Mechanical response of two-dimensional polymer networks: role of topology, rate dependence, and damage accumulation. J. Appl. Mech. 85, 031008 (2018). https://doi.org/10.1115/1.4038883

Katchalsky, A., Michaeli, I.: Polyelectrolyte gels in salt solutions. J. Polym. Sci. 15, 69–86 (1955). https://doi.org/10.1002/pol.1955.120157906

Landsgesell, J., Holm, C.: Cell model approaches for predicting the swelling and mechanical properties of polyelectrolyte gels. Macromolecules 52, 9341–9353 (2019). https://doi.org/10.1021/acs.macromol.9b01216

Schneider, S., Linse, P.: Swelling of cross-linked polyelectrolyte gels. Eur. Phys. J. E 8, 457–460 (2002). https://doi.org/10.1140/epje/i2002-10043-y

Mann, B.A., Kremer, K., Holm, C.: The swelling behavior of charged hydrogels. Macromol. Symp. 237, 90–107 (2006). https://doi.org/10.1002/masy.200650511

Lu, Z.Y., Hentschke, R.: Computer simulation study on the swelling of a polyelectrolyte gel by a Stockmayer solvent. Phys. Rev. E 67, 061807 (2003). https://doi.org/10.1103/PhysRevE.67.061807

Lei, J., Zhou, Z., Liu, Z.: Side chains and the insufficient lubrication of water in polyacrylamide hydrogel—a new insight. Polymers 11, 1845 (2019)

Lv, H.B., Leng, J.S., Liu, Y.J., et al.: Shape-memory polymer in response to solution. Adv. Eng. Mater. 10, 592–595 (2008). https://doi.org/10.1002/adem.200800002

Xu, S., Liu, Z.: Coupled theory for transient responses of conductive hydrogels with multi-stimuli. J. Mech. Phys. Solids 143, 104055 (2020). https://doi.org/10.1016/j.jmps.2020.104055

Li, Z., Liu, Z., Ng, T.Y., et al.: The effect of water content on the elastic modulus and fracture energy of hydrogel. Extreme Mech. Lett. 35, 100617 (2020). https://doi.org/10.1016/j.eml.2019.100617

Diani, J., Brieu, M., Gilormini, P.: Observation and modeling of the anisotropic visco-hyperelastic behavior of a rubberlike material. Int. J. Solids Struct. 43, 3044–3056 (2006). https://doi.org/10.1016/j.ijsolstr.2005.06.045

Drozdov, A.D., Sanporean, C.G., Christiansen, J.D.C.: Mechanical response of HEMA gel under cyclic deformation: viscoplasticity and swelling-induced recovery. Int. J. Solids Struct. 52, 220–234 (2015). https://doi.org/10.1016/j.ijsolstr.2014.10.009

Mao, Y., Lin, S., Zhao, X., et al.: A large deformation viscoelastic model for double-network hydrogels. J. Mech. Phys. Solids 100, 103–130 (2017). https://doi.org/10.1016/j.jmps.2016.12.011

Li, Y., Tang, S., Abberton, B.C., et al.: A predictive multiscale computational framework for viscoelastic properties of linear polymers. Polymer 53, 5935–5952 (2012). https://doi.org/10.1016/j.polymer.2012.09.055

Ducrot, E., Chen, Y., Bulters, M., et al.: Toughening elastomers with sacrificial bonds and watching them break. Science 344, 186–189 (2014). https://doi.org/10.1126/science.1248494

Bai, R., Yang, J., Morelle, X.P., et al.: Fatigue fracture of self-recovery hydrogels. ACS Macro Lett. 7, 312–317 (2018). https://doi.org/10.1021/acsmacrolett.8b00045

Li Webber, R.E., Creton, C., Brown, H.R., et al.: Large strain hysteresis and Mullins effect of tough double-network hydrogels. Macromolecules 40, 2919–2927 (2007). https://doi.org/10.1021/ma062924y

Parada, G.A., Zhao, X.: Ideal reversible polymer networks. Soft Matter 14, 5186–5196 (2018). https://doi.org/10.1039/c8sm00646f

Acknowledgements

The authors are grateful for the support from the National Natural Science Foundation of China (Grants 11820101001, 11572236 and 11372236), the Natural Science Foundation of Shaanxi Province (Grant 2020JQ-010), and the State Key Laboratory of Nonlinear Mechanics.

Author information

Authors and Affiliations

Corresponding author

Additional information

Executive Editor: Hai-Bao Lu

Rights and permissions

About this article

Cite this article

Lei, J., Li, Z., Xu, S. et al. Recent advances of hydrogel network models for studies on mechanical behaviors. Acta Mech. Sin. 37, 367–386 (2021). https://doi.org/10.1007/s10409-021-01058-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-021-01058-2