Abstract

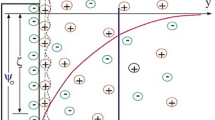

Temperature gradients aroused from the Joule heating in a non-uniform electrical field can induce inhomogeneities of electric conductivity and permittivity of the electrolyte, thus causing an electrothermal force that generates flow motion. A 2D numerical investigation of a micromixer, utilizing electrothermal effect to enhance its mixing efficiency, is proposed in this paper. Results for temperature and velocity distributions, as well as sample concentration distribution are obtained for an electrolyte solution in a microchannel with different pairs of electrodes under AC potentials with various frequencies. Numerical solutions were first carried out for one pair of electrodes, with a length of 10 μm separated by a gap of 10 μm, on one side wall of a microchannel having a length of 200 μm and a height of 50 μm. It is found that the electrothermal flow effect, in the frequency range for which Coulomb force is predominant, induces vortex motion near the electrodes, thus stirring the flow streams and enhancing its mixing efficiency. If more than one pair of electrodes is located on the opposite walls of the microchannel, the mixing efficiency depends on the AC potential applied pattern and the electrodes arrangement pattern. The distance between two pairs of electrodes on two opposite walls is then optimized numerically. Sample mixing efficiencies, using KCl solutions as the working fluid in microchannels with different number of electrodes pairs at optimal electrodes arrangement pattern, are also investigated. If root mean squared voltages of 10 V in an AC frequency range of 0.1–10 MHz are imposed on 16 pairs of electrodes separated at an optimal distance, the numerical results show that a mixing efficiency of 98% can be achieved at the end of the microchannel having a length of 700 μm and a height of 50 μm at Re = 0.01 Pe C = 100, and Pe T = 0.07. However, the mixing efficiency decreases sharply at a frequency higher than 10 MHz owing to the drastically decrease in the Coulomb force.

Similar content being viewed by others

Abbreviations

- a 1 :

-

distance between channel entrance and the left side of the first electrode on M side wall

- a 2 :

-

distance between channel entrance and the left side of the first electrode on N side wall

- Δa :

-

distance difference

- C :

-

sample concentration

- C 0 :

-

sample concentration profile with completely unmixed state

- C ∞ :

-

sample concentration profile with completely mixed state

- C 1in :

-

sample concentration at the upper part of the inlet

- C 2in :

-

sample concentration at the lower part of the inlet

- C pm :

-

heat capacity of the fluid

- d 1 :

-

length of the electrodes

- d 2 :

-

gap between the two electrodes in one pair

- d t :

-

channel length used by two pairs of electrodes at the two side walls

- D :

-

sample diffusion coefficient

- f c :

-

cross over frequency

- k :

-

thermal conductivity of the fluid

- L :

-

channel length

- p :

-

pressure

- p atm :

-

atmospheric pressure

- \({\overrightarrow{u}}\) :

-

velocity

- u 0 :

-

inlet velocity

- \(\widetilde{V}\) :

-

AC potential

- V rms :

-

root mean squared value of the AC potential

- V I :

-

imaginary part of the AC potential

- V R :

-

real part of the AC potential

- W :

-

channel height

- σ:

-

electric conductivity of the fluid

- ɛ:

-

the permittivity of the fluid

- ɛr :

-

relative permittivity of the fluid

- ɛ0 :

-

vacuum permittivity

- η:

-

dynamic viscosity of the fluid

- γ :

-

mixing efficiency parameter

- ρ m :

-

density of the fluid

References

Reyes DR, Lossifidis D, Auroux PA, Manz A (2002) Micro total analysis systems. 1. Introduction, theory, and technology. Anal Chem 74:2623–2636

Vilkner T, Janasek D, Manz A (2004) Micro total analysis systems, recent developments. Anal Chem 76:3373–3386

Jahn A, Vreeland WN, Gaitan M, Locascio LE (2004) Controlled vesicle self-assembly in microfluidic channels with hydrodynamic focusing. J Am Chem Soc 126:2674–2675

Wang HZ, Lovenitti P, Harvey E, Masood S (2003) Numerical investigation of mixing in microchannels with patterned grooves. J Micromech Microeng 13:801–808

Liu RH, Stremler MA, Sharp KV, Olsen MG, Santiago JG, Adrian RJ, Hassan A, Beebe DJ (2000) Passive mixing in a three-dimensional serpentine microchannel. J Microelectromech Syst 9:190–197

Erickson D, Li DQ (2002) Influence of surface heterogeneity on electrokinetically driven microfluidic mixing. Langmuir 18:1883–1892

Erickson D, Li DQ (2002) Microchannel flow with patchwise and periodic surface heterogeneity. Langmuir 18:8949–8959

Chang CC, Yang RJ (2004) Computational analysis of electrokinetically driven flow mixing in microchannels with patterned. Blocks J Micromech Microeng 14:550–558

Fu LM, Yang RJ, Lin CH, Chien YS (2005) A novel microfluidic mixer utilizing electrokinetic driving forces under low switching frequency. Electrophoresis 5:1814–1824

Shin SM, Kang LS, Cho YK (2005) Mixing enhancement by using electrokinetic instability under time-periodic electric field. J Micromech Microeng 15:455–462

Coleman JT, McKechnie J, Sinton D (2006) High-efficiency electrokinetic micromixing through symmetric sequential injection and expansion. Lab Chip 6:1033–1039

Ramos A, Morgan H, Green NG, Castellanos A (1998) AC electrokinetics: a review of forces in microelectrode structures. J Phys D Appl Phys 3:2340–2353

Green NG, Ramos A, González A, Castellanos A, Morgan H (2001) Electrothermally induced flow on microelectrodes. J Electrostatics 53:71–78

Hansen TS (2004) Simulation and testing of AC electroosmotic micropumps, Master thesis, Technical University of Denmark

Perch-Nielsen IR, Green NG, Wolff A (2004) Numerical simulation of travelling wave induced electrothermal fluid flow. J Phys D Appl Phys 37:2323- 2330

Brown ABD, Smith CG, Rennie AR (2006) Pumping of water with AC electric field applied to asymmetric pairs of microelectrodes. Phys Rev E 63 016305

Urbanski JP, Thorsen T, Levitan JA, Bazant MZ (2006) Fast AC electro-osmotic pumps with non-planar electrodes. Appl Phys Lett 89:143508

Chen DF, Du H (2006) Simulation studies on electrothermal fluid flow induced in a dielectrophoretic microelectrode system. J Micromech Microeng 116:2411–2419

González A, Ramos A, Morgan H, Green NG, Castellanos A (2006) Electrothermal flows generated by alternating and rotating electric fields in Microsystems. J Fluid Mech 564:415–433

Acknowledgments

This research work was supported by the National Natural Science Foundation of China through key project No. 50536010, and by Science and Technology Committee of Shanghai City Government through Key Fundamental Project No. 05JC14025.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, J., Cheng, P. & Hong, F.J. A numerical study of an electrothermal vortex enhanced micromixer. Microfluid Nanofluid 5, 13–21 (2008). https://doi.org/10.1007/s10404-007-0201-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-007-0201-4