Abstract

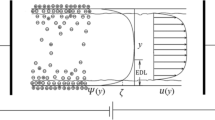

This paper presents a numerical investigation of electro-osmotic flow in heterogeneous microchannels employing the approximate Helmholtz-Smoluchowski model in which the effect of the electric field force is modeled as a velocity slip boundary condition on the fluid flow. The performance of mixing in such microchannels with implemented heterogeneous zeta-potential on their walls is examined through solving the concentration equation both qualitatively and quantitatively. This numerical study illustrates that merging two electro-osmotic and pressure-driven flows in a single microchannel with a suitable arrangement of heterogeneities can easily lead to devising an electro-osmotic micromixer with adjustable mixing performance. The behavior of such micromixers is mainly influenced by the arrangement of zeta-potential distribution and the amount of the applied external pressure drop. This paper introduces the relative mixing efficiency and mixing capacity and the well-discussed criterion of mixing performance to achieve a comprehensive mixing analysis. These factors show that heterogeneities do not significantly improve mixing under circumstances of an extremely small or large pressure drop. Therefore, the performance of micromixers with a combination of electro-osmotic and pressure-driven flows has an optimum point. It is also observed that the asymmetric degree of the charge pattern on the microchannel wall has a notable impact on the mixing efficiency of the micromixer compared to the absolute values of wall charges. This matter ensures that proper mixing can be achieved even with conventional/moderate zeta-potential surfaces in a micromixer.

Similar content being viewed by others

Abbreviations

- \(C\) :

-

Concentration (\({\text{mol m}}^{ - 3}\))

- \(C_{m}\) :

-

Mean concentration at each cross-section (\({\text{mol m}}^{ - 3}\))

- \(D\) :

-

Molecular diffusion coefficient (\({\text{m}}^{2} {\text{ s}}^{ - 1}\))

- \(E\) :

-

Electric field strength (\({\text{v m}}^{ - 1}\))

- \(E_{{{\text{ext}}}}\) :

-

Applied electric field strength (\({\text{v m}}^{ - 1}\))

- \({\text{E}}_{{{\text{Ch}},{\text{ r}}}}\) :

-

Relative mixing efficiency (−)

- \(H\) :

-

Microchannel height (\({\text{m}}\))

- \(L\) :

-

Channel length (\({\text{m}}\))

- \(P\) :

-

Pressure (\({\text{kg m}}^{ - 1} {\text{ s}}^{ - 2}\))

- \(Q_{{{\text{mix}}}}\) :

-

Mixing capacity (\({\text{nanoliter s}}^{ - 1}\))

- \({\text{Re}}\) :

-

Reynolds number (−)

- \({\text{Sc}}\) :

-

Schmidt number (−)

- \(u_{{{\text{wall}}}}\) :

-

Velocity on the wall (\({\text{m s}}^{ - 1}\))

- \(\vec{V}\) :

-

Velocity vector (\({\text{m s}}^{ - 1}\))

- \(\in_{{{\text{ms}}}}\) :

-

Mixing efficiency based on the concentration (−)

- \(\varepsilon\) :

-

Electrolyte permittivity coefficient (\({\text{c v}}^{ - 1} {\text{ m}}^{ - 1}\))

- \(\mu\) :

-

Dynamic viscosity (\({\text{kg m}}^{ - 1} {\text{ s}}^{ - 1}\))

- \(\zeta\) :

-

Zeta-potential (\({\text{v}}\))

- \(\zeta_{p}\) :

-

Zeta-potential in pumping section (\({\text{v}}\))

- \(\zeta_{m}\) :

-

Zeta-potential in middle section (\({\text{v}}\))

- \(\Psi_{0}\) :

-

Solid-liquid interface surface potential (\({\text{v}}\))

- \(\sigma\) :

-

Concentration deviation without weight function (\({\text{mol m}}^{ - 3}\))

- \(\sigma_{w}\) :

-

Concentration deviation with weight function (\({\text{mol m}}^{ - 3}\))

References

Hosseini HR, Nikookar H, Yesiloz G, Naseh M, Mohammadi M (2021) An overview on micropumps, micromixers, and their applications in bioprocess. In: Advances in Bioenergy and Microfluidic Applications, pp 365–386. https://doi.org/10.1016/B978-0-12-821601-9.00015-7

Farahinia A, Zhang WJ, Badea I (2021) Novel microfluidic approaches to circulating tumor cell separation and sorting of blood cells: a review. J Sci: Adv Mater Devices 6(3):303–320. https://doi.org/10.1016/j.jsamd.2021.03.005

Han W, Chen X (2020) Nano-electrokinetic ion enrichment in a micro-nanofluidic preconcentrator with nanochannel’s Cantor fractal wall structure. Appl Nanosci 10(1):95–105

Farahinia A, Jamaati J, Niazmand H (2017) Study of slip effect on electro-osmotic micromixer performance based on entropy index. Amirkabir J Mech Eng 49(3):535–548. https://doi.org/10.22060/mej.2016.776

Farahinia A, Zhang W (2020) Numerical analysis of a microfluidic mixer and the effects of different cross-sections and various input angles on its mixing performance. J Braz Soc Mech Sci Eng 42(4):1–18

Hong W, Shi H, Huang Z, Long M, Xu H, Liu Z (2019) Design and simulation of a passive micromixer with gourd-shaped channel. J Nanosci Nanotech 19(1):206–212

Rudyak V, Minakov A (2014) Modeling and optimization of Y-type micromixers. Micromachines 5(4):886–912

Farahinia A, Zhang WJ (2019) Numerical investigation into the mixing performance of micro T-mixers with different patterns of obstacles. J Braz Soc Mech Sci Eng 41(11):491–504. https://doi.org/10.1007/s40430-019-2015-1

Zhang S, Chen X, Wu Z, Zheng Y (2019) Numerical study on stagger Koch fractal baffles micromixer. Int J Heat and Mass Transfer 133:1065–1073

Ai B-q, Shao Z-g, Zhong W-r (2018) Mixing and demixing of binary mixtures of polar chiral active particles. Soft Matter 14(21):4388–4395

Han W, Chen X (2019) Nano-electrokinetic ion enrichment of highly viscous fluids in micro-nanochannel. Chem Eng Process-Process Intensif 143:107626

Farahinia A, Jamaati J, Niazmand H, Zhang W (2021) Numerical analysis of the heterogeneity effect on electroosmotic micromixers based on the standard deviation of concentration and mixing entropy index. Micromachines 12(9):1055

Almanza Álvarez G (2019) Microfluidics mixing using surface acoustic waves (SAW). NTNU, Norwegian University of Science and Technology

Zainal N, Abd Aziz N, Mutalib FAA, Buyong MR (2020) Chaotic mixing of microdroplets using surface acoustic waves device. J Adv Res Fluid Mech Therm Sci 73(1):13–24

Buyong MR, Kayani AA, Hamzah AA, Yeop Majlis B (2019) Dielectrophoresis manipulation: versatile lateral and vertical mechanisms. Biosensors 9(1):30

Lim CY, Lam YC, Yang C (2010) Mixing enhancement in microfluidic channel with a constriction under periodic electro-osmotic flow. Biomicrofluidics 4(1):014101. https://doi.org/10.1063/1.3279790

Liang YY, Fimbres Weihs GA, Wiley DE (2014) Approximation for modelling electro-osmotic mixing in the boundary layer of membrane systems. J Membr Sci 450:18–27. https://doi.org/10.1016/j.memsci.2013.08.031

Nayak AK (2014) Analysis of mixing for electroosmotic flow in micro/nano channels with heterogeneous surface potential. Int J Heat Mass Transf 75:135–144. https://doi.org/10.1016/j.ijheatmasstransfer.2014.03.057

Shanko E-S, van de Burgt Y, Anderson PD, den Toonder JM (2019) Microfluidic magnetic mixing at low reynolds numbers and in stagnant fluids. Micromachines 10(11):731

Dallakehnejad M, Mirbozorgi SA, Niazmand H (2019) A numerical investigation of magnetic mixing in electroosmotic flows. J Electrost 100:103354

Alizadeh A, Zhang L, Wang M (2014) Mixing enhancement of low-Reynolds electro-osmotic flows in microchannels with temperature-patterned walls. J Coll Interface Sci 431:50–63

Bahrani SA, Herbaut R, Royon L, Azzouz K, Bontemps A (2019) Experimental investigation of thermal and flow mixing enhancement induced by Rayleigh-like streaming in a milli-mixer. Therm Sci Eng Prog 14:100434

Bayareh M, Ashani MN, Usefian A (2020) Active and passive micromixers: a comprehensive review. Chem Eng Process-Process Intensif 147:107771

Mei L, Cui D, Shen J, Dutta D, Brown W, Zhang L, Dabipi IK (2021) Electroosmotic mixing of non-newtonian fluid in a microchannel with obstacles and zeta potential heterogeneity. Micromachines 12(4):431

Borgohain P, Arumughan J, Dalal A, Natarajan G (2018) Design and performance of a three-dimensional micromixer with curved ribs. Chem Eng Res Des 136:761–775

Buchegger W, Wagner C, Lendl B, Kraft M, Vellekoop M (2011) A highly uniform lamination micromixer with wedge shaped inlet channels for time resolved infrared spectroscopy. Microfluid Nanofluid 10:889–897

Tofteberg T, Skolimowski M, Andreassen E, Geschke O (2010) A novel passive micromixer: lamination in a planar channel system. Microfluid Nanofluid 8:209–215

Wang L, Liu D, Wang X, Han X (2012) Mixing enhancement of novel passive microfluidic mixers with cylindrical grooves. Chem Eng Sci 81:157–163

Tsai C-HD, Lin X-Y (2019) Experimental study on microfluidic mixing with different zigzag angles. Micromachines 10(9):583

Neerincx PE, Denteneer RPJ, Peelen S, Meijer HEH (2011) Compact mixing using multiple splitting, stretching, and recombining flows. Macromol Mater Eng 296:349–361

Altay R, Yetisgin AA, Erdem K, Koşar A (2021) The effect of varying radius of curvature on mixing in elliptical spiral microchannels. Chem Eng Process-Process Intensif 164:108

Bhattacharyya S, Bera S (2015) Combined electroosmosis-pressure driven flow and mixing in a microchannel with surface heterogeneity. Appl Math Model 39(15):4337–4350. https://doi.org/10.1016/j.apm.2014.12.050

Shi X, Huang S, Wang L, Li F (2021) Numerical analysis of passive micromixer with novel obstacle design. J Dispers Sci Technol 42(3):440–456

Hardt S, Pennemann H, Schönfeld F (2006) Theoretical and experimental characterization of a low-Reynolds number split-and-recombine mixer. Microfluid Nanofluid 2(3):237–248. https://doi.org/10.1007/s10404-005-0071-6

Ebrahimi S, Hasanzadeh-Barforoushi A, Nejat A, Kowsary F (2014) Numerical study of mixing and heat transfer in mixed electroosmotic/pressure driven flow through T-shaped microchannels. Int J Heat Mass Transf 75:565–580. https://doi.org/10.1016/j.ijheatmasstransfer.2014.04.004

Peng R, Li D (2015) Effects of ionic concentration gradient on electroosmotic flow mixing in a microchannel. J Colloid Interface Sci 440:126–132. https://doi.org/10.1016/j.jcis.2014.10.061

Ahmadian Yazdi A, Sadeghi A, Saidi MH (2015) Electrokinetic mixing at high zeta potentials: ionic size effects on cross stream diffusion. J Colloid Interface Sci 442:8–14. https://doi.org/10.1016/j.jcis.2014.11.059

Han W, Chen X (2020) A review: applications of ion transport in micro-nanofluidic systems based on ion concentration polarization. J Chem Technol Biotechnol 95(6):1622–1631

Hau WLW, Trau DW, Sucher NJ, Wong M, Zohar Y (2003) Surface-chemistry technology for microfluidics. J of Micromech Microeng 13(2):272–278

Stroock A, Weck M, Chiu D, Huck W, Kenis P, Ismagilov R, Whitesides G (2000) Patterning electro-osmotic flow with patterned surface charge. Phys Rev Lett 84(15):3314–3317

Schasfoort RBM, Schlautmann S, Hendrikse J, van den Berg A (1999) Field-effect flow control for microfabricated fluidic networks. Science 286(5441):942–945. https://doi.org/10.1126/science.286.5441.942

Peralta M, Arcos J, Méndez F, Bautista O (2020) Mass transfer through a concentric-annulus microchannel driven by an oscillatory electroosmotic flow of a Maxwell fluid. J Non-Newtonian Fluid Mech 279:104281

Ganguly S, Sarkar S, Kumar Hota T, Mishra M (2015) Thermally developing combined electroosmotic and pressure-driven flow of nanofluids in a microchannel under the effect of magnetic field. Chem Eng Sci 126:10–21. https://doi.org/10.1016/j.ces.2014.11.060

Manshadi MK, Mohammadi M, Zarei M, Saadat M, Sanati-Nezhad A (2020) Induced-charge electrokinetics in microfluidics: a review on recent advancements. J Micromech Microeng 30(11):113001

Ng CO, Qi C (2014) Electroosmotic flow of a power-law fluid in a non-uniform microchannel. J Non-Newton Fluid Mech 208–209:118–125. https://doi.org/10.1016/j.jnnfm.2014.04.008

Farahinia A, Jamaati J, Niazmand H (2019) Investigation of slip effects on electroosmotic mixing in heterogeneous microchannels based on entropy index. SN Appl Sci 1(7):728–740. https://doi.org/10.1007/s42452-019-0751-6

Farahinia A, Jamaati J, Niazmand H, Zhang WJ (2019) Investigation of an electro-osmotic micromixer with heterogeneous zeta-potential distribution at the wall. Eng Res Express 1(1):015024. https://doi.org/10.1088/2631-8695/ab3a15

Bera S, Bhattacharyya S (2013) On mixed electroosmotic-pressure driven flow and mass transport in microchannels. Int J Eng Sci 62:165–176. https://doi.org/10.1016/j.ijengsci.2012.09.006

Mondal M, Misra RP, De S (2014) Combined electroosmotic and pressure driven flow in a microchannel at high zeta potential and overlapping electrical double layer. Int J Therm Sci 86:48–59. https://doi.org/10.1016/j.ijthermalsci.2014.06.029

Alizadeh A, Hsu WL, Wang M, Daiguji H (2021) Electroosmotic flow: from microfluidics to nanofluidics. Electrophoresis 42(7–8):834–868

Mirbozorgi SA, Niazmand H, Renksizbulut M (2006) Electro-Osmotic Flow in Reservoir-Connected Flat Microchannels With Non-Uniform Zeta Potential. Journal of Fluids Engineering 128(6):1133–1143. https://doi.org/10.1115/1.2353261

Hadjigeorgiou AG, Boudouvis AG, Kokkoris G (2021) Thorough computational analysis of the staggered herringbone micromixer reveals transport mechanisms and enables mixing efficiency-based improved design. Chem Eng J 414:128775

Qaderi A, Jamaati J, Bahiraei M (2019) CFD simulation of combined electroosmotic-pressure driven micro-mixing in a microchannel equipped with triangular hurdle and zeta-potential heterogeneity. Chem Eng Sci 199:463–477. https://doi.org/10.1016/j.ces.2019.01.034

Niazmand H, Jamaati J, Renlsizbulut M (2013) Investigation of electrokinetic mixing in 3D non-homogenous microchannels. J Comput Appl Res Mech Eng 3(1):41–52

Rhie CM, Chow WL (1983) Numerical study of the turbulent flow past an airfoil with trailing edge separation. AIAA J 21(11):1525–1532. https://doi.org/10.2514/3.8284

Zhang J, He G, Liu F (2006) Electro-osmotic flow and mixing in heterogeneous microchannels. Phys Rev E 73(5):056305ss

Wj Z, Pr O, Zh S (2010) A novel hybridization design principle for intelligent mechatronics systems. In: The Abstracts of the international conference on advanced mechatronics: toward evolutionary fusion of IT and mechatronics: ICAM 2010.5, 2010. The Japan Society of Mechanical Engineers, pp 67–74. https://doi.org/10.1299/jsmeicam.2010.5.67

Yuan C, Tony A, Yin R, Wang K, Zhang W (2021) Tactile and thermal sensors built from carbon–polymer nanocomposites—A critical review. Sensors 21(4):1234

Zhang W, Van Luttervelt C (2011) Toward a resilient manufacturing system. CIRP Annals 60(1):469–472

Acknowledgments

The authors gratefully acknowledge the mechanical engineering departments at the Ferdowsi University of Mashhad and the University of Saskatchewan for providing us the research facilities. The research is also made possible to the first author by the Devolved Graduate Scholarships and NSERC Discovery Grant to WJ.

Funding

This research work is not supported by any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Daniel Onofre de Almeida Cruz.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farahinia, A., Jamaati, J., Niazmand, H. et al. The effect of heterogeneous surface charges on mixing in a combined electroosmotic/pressure-driven micromixer. J Braz. Soc. Mech. Sci. Eng. 43, 497 (2021). https://doi.org/10.1007/s40430-021-03215-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-03215-x