Abstract

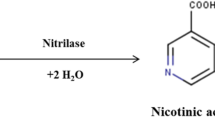

Nitrilase of Nocardia globerula NHB-2 was induced by short-chain aliphatic nitriles (valeronitrile > isobutyronitrile > butyronitrile > propionitrile) and exhibited activity towards aromatic nitriles (benzonitrile > 3-cyanopyridine > 4-cyanopyridine > m-tolunitrile > p-tolunitrile). Hyperinduction of nitrilase (6.67 U mg −1DCW , 18.7 U mL−1) was achieved in short incubation time (30 h, 30°C) through multiple feeding of isobutyronitrile in the growth medium. The nitrilase of this organism exhibits both substrate and product inhibition effects. In a fed batch reaction at 1 L scale using hyperinduced resting cells corresponding to 10 U mL−1 nitrilase activity (1.5 mgDCW mL−1), a total of 123.11 g nicotinic acid was produced at a rate of 24 g h−1 g −1DCW .

Similar content being viewed by others

References

Almatawah QA, Cowan DA (1999) Thermostable nitrilase catalysed production of nicotinic acid from 3-cyanopyridine. Enz Microb Technol 25:718–724

Bhalla TC, Kumar H (2005) Nocardia globerula NHB-2: a versatile nitrile-degrading organism. Can J Microbiol 51:705–708

Breuer M, Ditrich K, Habicher T, Hauer B, Keβeler M, Stürmer R, Zelinski T (2004) Industrial methods for the production of optically active intermediates. Angewandte Chemie Int Ed 43:788–824

Bunch AW (1998) Biotransformation of nitriles by Rhodococci. Antonie Van Leeuwenhoek 74:89–97

Chuck R (2005) Technology development in nicotinate production. Appl Catal A Gen 280:75–82

Copeland RA (2000) Enzymes, 2nd edn. Wiley, New York

DeSantis G, Wong K, Farwell B, Chatman K, Zhu Z, Tomlinson G, Huang H, Tan X, Bibbs L, Chen P, Kretz K, Burk MJ (2003) Creation of a productive, highly enantioselective nitrilase through gene site saturation mutagenesis (GSSM). J Am Chem Soc 125:11476–11477

Fawcett JK, Scott JE (1960) A rapid and precise method for the determination of urea. J Clin Pathol 13:156–159

Hatanaka M, Tanaka N (1993) World Patent 93.5022 A1, March 18, 1993

Kaplan O, Vejvoda V, Plíhal O, Pompach P, Kavan D, Bojarová P, Bezouška K, Macková M, Cantarella M, Jirků V, Křen V, Martínková L (2006) Purification and characterization of a nitrilase from Aspergillus niger K10. Appl Microbiol Biotechnol 73:567–575

Kobayashi M, Yanaka N, Nagasawa T, Yamada H (1990) Purification and characterization of a novel nitrilase of Rhodococcus rhodochrous K22 that acts on aliphatic nitriles. J Bact 172:4807–4815

Kobayashi M, Yanaka N, Nagasawa T, Yamada H (1991) Hpyerinduction of an aliphatic nitrilase by Rhodococcus rhodochrous K22. FEMS Microbiol Lett 77:121–124

Mathew CD, Nagasawa T, Kobayashi M, Yamada H (1988) Nitrilase-catalyzed production of nicotinic acid from 3-cyanopyridine in Rhodococcus rhodochrous JI. Appl Microbiol Biotechnol 54:1030–1032

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nagasawa T, Mathew CD, Mauger J, Yamada H (1988) Nitrile hydratase-catalyzed production of nicotinamide from 3-cyanopyridine in Rhodococcus rhodochrous J1. Appl Env Microbiol 54:166–169

Nagasawa T, Nakamura T, Yamada H (1988) Optimum culture conditions for the production of benzonitrilase by Rhodococcus rhodochrous J1. Arch Micobiol 150:89–94

Nagasawa T, Nakamura T, Yamada H (1990) ε-Caprolactam, a new powerful inducer for the formation of Rhodococcus rhodochrous J1 nitrilase. Arch Micobiol 155:13–17

Nagasawa T, Shimizu H, Yamada H (1993) Superiority of the third generation catalyst Rhodococcus rhodochrous J1 nitrile hydratase for industrial production of acrylamide. Appl Microbiol Biotechnol 40:189–195

O’Reilly C, Turner PD (2003) The nitrilase family of CN hydrolysing enzymes–a comparative study. J Appl Microbiol 95:1161–1174

Pace HC, Brenner C (2001) The nitrilase superfamily: classification, structure and function. Genome Biol 2:1–9

Prasad S, Raj J, Bhalla TC (2007) Bench scale conversion of 3-cyanopyridine to nicotinamide using resting cells of Rhodococcus rhodochrous PA-34. Ind J Microbiol 47:34–41

Raj J, Prasad S, Bhalla TC (2006) Rhodococcus rhodochrous PA-34: a potential biocatalyst for acrylamide synthesis. Process Biochem 41:1359–1363

Sharma NN, Sharma M, Kumar H, Bhalla TC (2006) Nocardia globerula NHB-2: bench scale production of nicotinic acid. Process Biochem 41:2078–2081

Sheldon RA, Arends I, Hanefeld U (2007) Green chemistry and catalysis. Wiley-VCH Verlag, Weinheim

Toomey Jr JE (1984) United States Patent 4,482,439 A, November 13, 1984

Vaughan PA, Knowles CJ, Cheetham PSJ (1989) Conversion of 3-cyanopyridine to nicotinic acid by Nocardia rhodococcus LL100–21. Enzym Microb Technol 11:815–823

Wang M-X (2005) Enantioselective biotransformations of nitriles in organic synthesis. Topic Catal 35:117–130

Weissermel K, Arpe H-J (1997) Industrial organic chemistry, 3rd edn. Wiley-VCH Verlag, Weinheim

Wu S, Fogiel AJ, Petrillo KL, Hann EC, Mersinger LJ, DiCosimo R, O’Keefe DP, Ben-Bassat A, Payne MS (2007) Protein engineering of Acidovorax facilis 72 W nitrilase for bioprocess development. Biotechnol Bioeng 97:689–693

Wu S, Fogiel AJ, Petrillo KL, Jackson JE, Parker KN, DiCosimo R, O’Keefe DP, Ben-Bassat A, O’Keefe DP, Payne MS (2008) Protein engineering of nitrilase for chemoenzymatic production of glycolic acid. Biotechnol Bioeng 99:717–720

Yamada H (1992) New biocatalytic functions of microorganisms and their industrial applications. Biochem Eng 2001:14–17

Yeom S-J, Kim H-J, Lee J-K, Kim D-E, Oh D-K (2008) An amino acid at position 142 in nitrilase from Rhodococcus rhodochrous ATCC 33278 determines the substrate specificity for aliphatic and aromatic nitriles. Biochem J 415:401–407

Acknowledgments

The authors acknowledge the Council of Scientific and Industrial Research, New Delhi for financial support in the form of Senior Research Fellowship to Mr Nitya Nand Sharma and Ms Monica Sharma. The computational facility availed at Bioinformatics Centre, H P University is also duly acknowledged. The authors also thank Jubilant Organosis (India) for the gift of 3-CP.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, N.N., Sharma, M. & Bhalla, T.C. An improved nitrilase-mediated bioprocess for synthesis of nicotinic acid from 3-cyanopyridine with hyperinduced Nocardia globerula NHB-2. J Ind Microbiol Biotechnol 38, 1235–1243 (2011). https://doi.org/10.1007/s10295-010-0902-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0902-7