Abstract

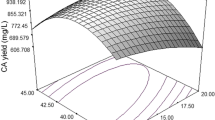

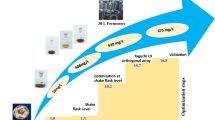

Hyaluronic acid (HA), linear high-molecular-weight glycosaminoglycan produced from Streptococcus sp., has raised interest in the medical and cosmetics industries because of the various biological functions of HA. In this paper, we report on the optimization of medium components for HA production in Streptococcus sp. ID9102 (KCTC 11935BP) by two-step optimization (one-factor-at-a-time and taguchi orthogonal array design). In the first step, medium components, such as carbon, nitrogen, phosphate, and mineral sources, were selected for HA production in Streptococcus sp. ID9102 (KCTC 11935BP) using the one-factor-at-a-time method. In the second step, the concentration of the selected medium components was optimized using taguchi orthogonal array design. The design for medium optimization was developed and analyzed using MINITAB 14 software. In addition, the effect of amino acid and organic acid, such as glutamine, glutamate, and oxalic acid, was studied for HA production in Streptococcus sp. ID9102 (KCTC 11935BP). Through these processes, the optimum medium comprising 4% glucose, 0.75% yeast extract, 1.0% casein peptone, 0.25% K2HPO4, 0.05% MgCl2, 0.5% NaCl, 0.04% glutamine, 0.06% glutamate, and 0.02% oxalic acid was determined. We were able to produce HA with a molecular weight of 5.9 × 106 at a productivity of 6.94 g/l on pilot scale fermentation.

Similar content being viewed by others

References

Armstrong DC, Johns MR (1997) Culture conditions affect the molecular weight properties of hyaluronic acid produced by Streptococcus zooepidemicus. Appl Environ Microbiol 63:2759–2764

Biotechnology General Corporation (1986) Method of producing high molecular weight sodium hyaluronate by fermentation of Streptococcus. World patent WO 8604355

Blank LM, McLaughlin RL, Nielsen LK (2005) Stable production of hyaluronic acid in Streptococcus zooepidemicus chemostats operated at high dilution rate. Biotechnol Bioeng 90:685–693

Chong BF, Blank LM, Mclaughlin R, Nielsen LK (2005) Microbial hyaluronic acid production. Appl Microbiol Biotechnol 66:341–351

Chong BF, Nielsen LK (2003) Amplifying the cellular reduction potential of Streptococcus zooepidemicus. J Biotechnol 100:33–41

Chong BF, Nielsen LK (2003) Aerobic cultivation of Streptococcus zooepidemicus and the role of NADH oxidase. Biochem Eng J 16:153–162

Cooney MJ, Goh LT, Lee PL, Johns MR (1999) Structured model-based analysis and control of the hyaluronic acid fermentation by Streptococcus zooepidemicus: physiological implications of glucose and complex-nitrogen-limited growth. Biotechnol Prog 15:898–910

DeAngelis PL (1999) Hyaluronan synthases: fascinating glycosyltransferases from vertebrates, bacterial pathogens, and algal viruses. Cell Mol Life Sci 56:670–682

Denki Kagaku Kogyo KK (1993) Manufacture of hyaluronic acid with Streptococcus equi. Japanese patent 9:3–195924

Duan XJ, Yang L, Zhang X, Tan WS (2008) Effect of oxygen and shear stress on molecular weight of hyaluronic acid produced by Streptococcus zooepidemicus. J Microbiol Biotechnol 18:718–724

Ferrante ND (1956) Turbidity measurement of acid mucopolysaccharides and hyaluronidase activity. J Biol Chem 220:303–306

Goa KL, Benfield P (1994) Hyaluronic acid: a review of its pharmacology and use as a surgical aid in ophthalmology and its therapeutic potential in joint disease and wound healing. Drug 47:536–566

Hasegawa S, Nagatsuru M, Shibutani M, Yamamoto S, Hasebe S (1999) Productivity of concentrated hyaluronic acid using a Maxblend® fermentor. J Biosci Bioeng 99:521–518

Huang WC, Chen SJ, Chen TL (2006) The role of dissolved oxygen and function of agitation in hyaluronic acid fermentation. Biochem Eng J 32:239–243

Huang WC, Chen SJ, Chen TL (2008) Production of hyaluronic acid by repeated batch fermentation. Biochem Eng J 40:460–464

Johns MR, Goh LT, Oeggerli A (1994) Effect of pH, agitation and aeration on hyaluronic-acid production by Streptococcus zooepidemicus. Biotechnol Lett 16:507–512

Khieokhachee T (1994) Kinetic studies of cheese starter cultures. Ph.D. thesis, University of New South Wales

Kim JH, Yoo SJ, Oh DK, Kweon YG (1996) Selection of a Streptococcus equi mutant and optimization of culture conditions for the production of high molecular weight hyaluronic acid. Enzyme Microb Technol 19:440–445

Kim SJ, Park SY, Kim CW (2006) A novel approach to the production of hyaluronic acid by Streptococcus zooepidemicus. J Microbiol Biotechnol 16:1849–1855

Kogan G, Soltes L, Stern R, Gemeiner P (2007) Hyaluronic acid: a natural biopolymer with a broad range of biomedical and industrial applications. Biotechnol Lett 29:17–25

Liu L, Wang M, Du G, Chen J (2008) Enhanced hyaluronic acid production of Streptococcus zooepidemicus by and intermittent alkaline-stress strategy. Lett Appl Microbiol 46:383–388

Liu L, Wang M, Du G, Chen J (2008) Enhanced hyaluronic acid production by a two-stage culture strategy based on the modeling of batch and fed-batch cultivation of Streptococcus zooepidemicus. Bioresour Technol 99:8532–8536

Liu L, Du G, Chen J, Zhu Y, Wang M, Sun J (2009) Microbial production of low molecular weight hyaluronic acid by adding hydrogen peroxide and ascorbate in batch culture of Streptococcus zooepidemicus. Bioresour Technol 100:362–367

Ogrodowski CS, Hokka CO, Santana MHA (2005) Production of hyaluronic acid by Streptococcus: the effects of the addition of lysozyme and aeration on the formation and the rheological properties of the product. Appl Biochem Biotechnol 5:121–124

O’Regan M, Martini I, Crescenzi F, De Luca C, Lansing M (1994) Molecular mechanisms and genetics of hyaluronan biosynthesis. Int J Biol Macromol 16:283–286

Park MG, Jang JD, Kang WK (1996) Streptococcus zooepidemicus medium and process for preparing hyaluronic acid. US patent 5496726

Rangaswamy V, Jain D (2008) An efficient process for production and purification of hyaluronic acid from Streptococcus equi subsp. zooepidemicus. Biotechnol Lett 30:493–496

Stangohl S (2000) Methods and means for the production of hyaluronic acid. US Patent 6090596

Swann DA, Sukkivan BP, Jamieson G, Richardson KR, Singh T (1990) Biosynthesis of hyaluronic acid. US Patent 4897349

Zhang J, Ding X, Yang L, Kong Z (2006) A serum-free medium for colony growth and hyaluronic acid production by Streptococcus zooepidemicus NJUST01. Appl Microbiol Biotechnol 72:168–172

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Im, JH., Song, JM., Kang, JH. et al. Optimization of medium components for high-molecular-weight hyaluronic acid production by Streptococcus sp. ID9102 via a statistical approach. J Ind Microbiol Biotechnol 36, 1337–1344 (2009). https://doi.org/10.1007/s10295-009-0618-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-009-0618-8