Abstract

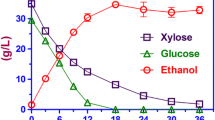

A potential industrial substrate (liquefied corn starch; LCS) has been employed for successful acetone butanol ethanol (ABE) production. Fermentation of LCS (60 g l−1) in a batch process resulted in the production of 18.4 g l−1 ABE, comparable to glucose: yeast extract based medium (control experiment, 18.6 g l−1 ABE). A batch fermentation of LCS integrated with product recovery resulted in 92% utilization of sugars present in the feed. When ABE was recovered by gas stripping (to relieve inhibition) from the fed-batch reactor fed with saccharified liquefied cornstarch (SLCS), 81.3 g l−1 ABE was produced compared to 18.6 g l−1 (control). In this integrated system, 225.8 g l−1 SLCS sugar (487 % of control) was consumed. In the absence of product removal, it is not possible for C. beijerinckii BA101 to utilize more than 46 g l−1 glucose. A combination of fermentation of this novel substrate (LCS) to butanol together with product recovery by gas stripping may economically benefit this fermentation.

Similar content being viewed by others

References

Annous BA, Blaschek HP (1991) Isolation and characterization of Clostridium acetobutylicum mutants with enhanced amylolytic activity. Appl Environ Microbiol 57:2544–2548

Bergmeyer HU, Grassel M (1983) Reagents for enzymatic analysis: enzymes––α-amylase. In: Bergmeyer HU (ed) Methods of enzymatic analysis, 3rd edn, vol. 2. Chemie, Weinhiem, Germany, pp 151–152

Campos EJ, Qureshi N, Blaschek HP (2002) Production of acetone butanol ethanol from degermed corn using Clostridium beijerinckii BA101. J Appl Biochem Biotechnol 98:553–561

Dürre P (1998) New insights and novel developments in clostridial acetone/butanol/isopropanol fermentation. Appl Microbiol Biotechnol 49:639–648

Ezeji TC, Qureshi N, Blaschek HP (2005) Continuous butanol fermentation and feed starch retrogradation: butanol fermentation sustainability using Clostridium beijerinckii BA101. J Biotechnol 115:179–187

Ezeji TC, Qureshi N, Blaschek HP (2004) Acetone–butanol–ethanol (ABE) production from concentrated substrate: reduction in substrate inhibition by fed-batch technique and product inhibition by gas stripping. Appl Microbiol Biotechnol 23:653–658

Ezeji TC, Qureshi N, Blaschek HP (2003) Production of butanol by Clostridium beijerinckii BA101 and in-situ recovery by gas stripping. World J Microbiol Biotechnol 19:595–603

Formanek J, Mackie R, Blaschek HP (1997) Enhanced butanol production by Clostridium beijerinckii BA101 grown in semi-defined P2 medium containing 6 percent maltodextrin or glucose. Appl Environ Microbiol 63:2306–2310

Hull S, Yang BY, Venzke D, Kulhavy K, Montgomery R (1996) Composition of corn steep water during steeping. J Agric Food Chem 44:1857–1863

Industrial Bioprocessing “DuPont and BP will produce butanol for motor fuel”, 28 (7) July 2006

Jesse TW, Ezeji TC, Qureshi N, Blaschek HP (2002) Production of butanol from starch-based waste packing peanuts and agricultural waste. J Ind Microbiol Biotechnol 29:117–123

Joint Expert Committee on Food Additives (JECFA), Compendum of food additives specifications, Addendum 7. FAO food and nutrition paper (FNP), No.52, Add. 7 (1999) http://apps3.fao.org/jecfa/additive_specs/docs/7/additive-0779.htm

Maddox IS (1989) The acetone butanol ethanol fermentation: recent progress in technology. Biotechnol Genet Eng Rev 7:189–220

Marlatt JA, Datta R (1986) Acetone-butanol fermentation process development and economic evaluation. Biotechnol Prog 2:23–28

Qureshi N, Blaschek HP (1999) Production of acetone butanol ethanol (ABE) by a hyper producing mutant strain of Clostridium beijerinckii BA101 and recovery by pervaporation. Biotechnol Prog 15:594–602

Qureshi N, Maddox IS, Friedl A (1992) Application of continuous substrate feeding to the ABE fermentation: relief of product inhibition using extraction, perstraction, stripping, and pervaporation. Biotechnol Prog 8:382–390

Schoutens GH, Groot WJ (1985) Economic feasibility of the production of iso-propanol–butanol–ethanol fuels from whey permeate. Process Biochem 8:1–5

Acknowledgments

This work was supported in part by Illinois Council on Food and Agricultural Research (CFAR) grant number IDA CF 03E116-1 FSHN and Illinois Corn Marketing Board (ICMB). Authors would like to thank Archer Daniels Midland Company (Decatur, Illinois) for supplying LCS and CSL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names of commercial products in this article/publication is solely for the purpose of providing scientific information and does not imply recommendation or endorsement by the United States Department of Agriculture.

Rights and permissions

About this article

Cite this article

Ezeji, T.C., Qureshi, N. & Blaschek, H.P. Production of acetone butanol (AB) from liquefied corn starch, a commercial substrate, using Clostridium beijerinckii coupled with product recovery by gas stripping. J Ind Microbiol Biotechnol 34, 771–777 (2007). https://doi.org/10.1007/s10295-007-0253-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-007-0253-1