Abstract

Biomechanical study of brain injuries originated from mechanical damages to white matter tissue requires detailed information on mechanical characteristics of its main components, the axonal fibers and extracellular matrix, which is very limited due to practical difficulties of direct measurement. In this paper, a new theoretical framework was established based on microstructural modeling of brain white matter tissue as a soft composite for bidirectional hyperelastic characterization of its main components. First the tissue was modeled as an Ogden hyperelastic material, and its principal Cauchy stresses were formulated in the axonal and transverse directions under uniaxial and equibiaxial tension using the theory of homogenization. Upon fitting these formulae to the corresponding experimental test data, direction-dependent hyperelastic constants of the tissue were obtained. These directional properties then were used to estimate the strain energy stored in the homogenized model under each loading scenario. A new microstructural composite model of the tissue was also established using principles of composites micromechanics, in which the axonal fibers and surrounding matrix are modeled as different Ogden hyperelastic materials with unknown constants. Upon balancing the strain energies stored in the homogenized and composite models under different loading scenarios, fully coupled nonlinear equations as functions of unknown hyperelastic constants were derived, and their optimum solutions were found in a multi-parametric multi-objective optimization procedure using the response surface methodology. Finally, these solutions were implemented, in a bottom-up approach, into a micromechanical finite element model to reproduce the tissue responses under the same loadings and predict the tissue responses under unseen non-equibiaxial loadings. Results demonstrated a very good agreement between the model predictions and experimental results in both directions under different loadings. Moreover, the axonal fibers with hyperelastic characteristics stiffer than the extracellular matrix were shown to play the dominant role in directional reinforcement of the tissue.

Similar content being viewed by others

References

Abolfathi N, Naik A, Sotudeh Chafi M et al (2009) A micromechanical procedure for modelling the anisotropic mechanical properties of brain white matter. Comput Methods Biomech Biomed Eng 12:249–262. https://doi.org/10.1080/10255840903097871

Arbogast KB (1997) A characterization of the anisotropic mechanical properties of the brainstem. University of Pennsylvania, Philadelphia

Arbogast KB, Margulies SS (1999) A fiber-reinforced composite model of the viscoelastic behavior of the brainstem in shear. J Biomech 32:865–870

Bain AC, Shreiber DI, Meaney DF (2003) Modeling of microstructural kinematics during simple elongation of central nervous system tissue. J Biomech Eng 125:798–804

Bernal R, Pullarkat PA, Melo F (2007) Mechanical properties of axons. Phys Rev Lett 99:018301. https://doi.org/10.1103/PhysRevLett.99.018301

Bezerra MA, Santelli RE, Oliveira EP et al (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76:965–977. https://doi.org/10.1016/j.talanta.2008.05.019

Biles WE (1975) A response surface method for experimental optimization of multi-response processes. Ind Eng Chem Process Des Dev 14:152–158. https://doi.org/10.1021/i260054a010

Budday S, Nay R, de Rooij R et al (2015) Mechanical properties of gray and white matter brain tissue by indentation. J Mech Behav Biomed Mater 46:318–330. https://doi.org/10.1016/j.jmbbm.2015.02.024

Chatelin S, Deck C, Renard F et al (2011) Computation of axonal elongation in head trauma finite element simulation. J Mech Behav Biomed Mater 4:1905–1919. https://doi.org/10.1016/j.jmbbm.2011.06.007

Chatelin S, Vappou J, Roth S et al (2012) Towards child versus adult brain mechanical properties. J Mech Behav Biomed Mater 6:166–173. https://doi.org/10.1016/j.jmbbm.2011.09.013

Chatelin S, Deck C, Willinger R (2013) An anisotropic viscous hyperelastic constitutive law for brain material finite-element modeling. J Biorheol 27:26–37. https://doi.org/10.1007/s12573-012-0055-6

Cloots RJH, van Dommelen JAW, Nyberg T et al (2011) Micromechanics of diffuse axonal injury: influence of axonal orientation and anisotropy. Biomech Model Mechanobiol 10:413–422. https://doi.org/10.1007/s10237-010-0243-5

de Rooij R, Kuhl E (2016) Constitutive modeling of brain tissue: current perspectives. Appl Mech Rev 68:010801. https://doi.org/10.1115/1.4032436

Eskandari F, Shafieian M, Aghdam MM, Laksari K (2021) Tension strain-softening and compression strain-stiffening behavior of brain white matter. Ann Biomed Eng 49:276–286. https://doi.org/10.1007/s10439-020-02541-w

Feng Y, Okamoto RJ, Namani R et al (2013) Measurements of mechanical anisotropy in brain tissue and implications for transversely isotropic material models of white matter. J Mech Behav Biomed Mater 23:117–132. https://doi.org/10.1016/j.jmbbm.2013.04.007

Feng Y, Lee C-H, Sun L et al (2017) Characterizing white matter tissue in large strain via asymmetric indentation and inverse finite element modeling. J Mech Behav Biomed Mater 65:490–501. https://doi.org/10.1016/j.jmbbm.2016.09.020

Giordano C, Kleiven S (2014) Connecting fractional anisotropy from medical images with mechanical anisotropy of a hyperviscoelastic fibre-reinforced constitutive model for brain tissue. J R Soc Interface 11:20130914. https://doi.org/10.1098/rsif.2013.0914

Goriely A, Budday S, Kuhl E (2015a) Neuromechanics: from neurons to brain. Adv Appl Mech 48:79–139

Goriely A, Geers MGD, Holzapfel GA et al (2015b) Mechanics of the brain: perspectives, challenges, and opportunities. Biomech Model Mechanobiol 14:931–965. https://doi.org/10.1007/s10237-015-0662-4

Guertler CA, Okamoto RJ, Schmidt JL et al (2018) Mechanical properties of porcine brain tissue in vivo and ex vivo estimated by MR elastography. J Biomech 69:10–18. https://doi.org/10.1016/j.jbiomech.2018.01.016

Ingber DE, Heidemann SR, Lamoureux P, Buxbaum RE (2000) Opposing views on tensegrity as a structural framework for understanding cell mechanics. J Appl Physiol 89:1663–1678. https://doi.org/10.1152/jappl.2000.89.4.1663

Javid S, Rezaei A, Karami G (2014) A micromechanical procedure for viscoelastic characterization of the axons and ECM of the brainstem. J Mech Behav Biomed Mater 30:290–299. https://doi.org/10.1016/j.jmbbm.2013.11.010

Jiménez FL (2014) Modeling of soft composites under three-dimensional loading. Compos Part B Eng 59:173–180. https://doi.org/10.1016/j.compositesb.2013.11.020

Johnson CL, Telzer EH (2018) Magnetic resonance elastography for examining developmental changes in the mechanical properties of the brain. Dev Cogn Neurosci 33:176–181. https://doi.org/10.1016/j.dcn.2017.08.010

Johnson CL, McGarry MDJ, Gharibans AA et al (2013) Local mechanical properties of white matter structures in the human brain. Neuroimage 79:145–152. https://doi.org/10.1016/j.neuroimage.2013.04.089

Karami G, Grundman N, Abolfathi N et al (2009) A micromechanical hyperelastic modeling of brain white matter under large deformation. J Mech Behav Biomed Mater 2:243–254. https://doi.org/10.1016/j.jmbbm.2008.08.003

Kaster T, Sack I, Samani A (2011) Measurement of the hyperelastic properties of ex vivo brain tissue slices. J Biomech 44:1158–1163. https://doi.org/10.1016/j.jbiomech.2011.01.019

Labus KM, Puttlitz CM (2016a) An anisotropic hyperelastic constitutive model of brain white matter in biaxial tension and structural–mechanical relationships. J Mech Behav Biomed Mater 62:195–208. https://doi.org/10.1016/j.jmbbm.2016.05.003

Labus KM, Puttlitz CM (2016b) Viscoelasticity of brain corpus callosum in biaxial tension. J Mech Phys Solids 96:591–604. https://doi.org/10.1016/j.jmps.2016.08.010

Laksari K, Shafieian M, Darvish K (2012) Constitutive model for brain tissue under finite compression. J Biomech 45:642–646. https://doi.org/10.1016/j.jbiomech.2011.12.023

Li Z, Ji C, Li D et al (2020) A comprehensive study on the mechanical properties of different regions of 8-week-old pediatric porcine brain under tension, shear, and compression at various strain rates. J Biomech 98:109380. https://doi.org/10.1016/j.jbiomech.2019.109380

Li W, Shepherd DET, Espino DM (2021) Dynamic mechanical characterization and viscoelastic modeling of bovine brain tissue. J Mech Behav Biomed Mater 114:104204. https://doi.org/10.1016/j.jmbbm.2020.104204

Liu Y-L, Liu D, Xu L et al (2018) In vivo and ex vivo elastic properties of brain tissues measured with ultrasound elastography. J Mech Behav Biomed Mater 83:120–125. https://doi.org/10.1016/j.jmbbm.2018.04.017

MacManus DB, Pierrat B, Murphy JG, Gilchrist MD (2016) Mechanical characterization of the P56 mouse brain under large-deformation dynamic indentation. Sci Rep 6:21569. https://doi.org/10.1038/srep21569

McIlvain G, Schwarb H, Cohen NJ et al (2018) Mechanical properties of the in vivo adolescent human brain. Dev Cogn Neurosci 34:27–33. https://doi.org/10.1016/j.dcn.2018.06.001

Meaney DF (2003) Relationship between structural modeling and hyperelastic material behavior: application to CNS white matter. Biomech Model Mechanobiol 1:279–293. https://doi.org/10.1007/s10237-002-0020-1

Ning X, Zhu Q, Lanir Y, Margulies SS (2006) A transversely isotropic viscoelastic constitutive equation for brainstem undergoing finite deformation. J Biomech Eng 128:925. https://doi.org/10.1115/1.2354208

Pan Y, Sullivan D, Shreiber DI, Pelegri AA (2013) Finite element modeling of CNS white matter kinematics: use of a 3D RVE to determine material properties. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2013.00019

Pervin F, Chen WW (2009) Dynamic mechanical response of bovine gray matter and white matter brain tissues under compression. J Biomech 42:731–735. https://doi.org/10.1016/j.jbiomech.2009.01.023

Pfister BJ, Weihs TP, Betenbaugh M, Bao G (2003) An in vitro uniaxial stretch model for axonal injury. Ann Biomed Eng 31:589–598

Prevost TP, Balakrishnan A, Suresh S, Socrate S (2011) Biomechanics of brain tissue. Acta Biomater 7:83–95. https://doi.org/10.1016/j.actbio.2010.06.035

Rashid B, Destrade M, Gilchrist MD (2012a) Mechanical characterization of brain tissue in compression at dynamic strain rates. J Mech Behav Biomed Mater 10:23–38. https://doi.org/10.1016/j.jmbbm.2012.01.022

Rashid B, Destrade M, Gilchrist MD (2012b) Inhomogeneous deformation of brain tissue during tension tests. Comput Mater Sci 64:295–300. https://doi.org/10.1016/j.commatsci.2012.05.030

Sack I, Beierbach B, Wuerfel J et al (2009) The impact of aging and gender on brain viscoelasticity. Neuroimage 46:652–657. https://doi.org/10.1016/j.neuroimage.2009.02.040

Sahoo D, Deck C, Willinger R (2014) Development and validation of an advanced anisotropic visco-hyperelastic human brain FE model. J Mech Behav Biomed Mater 33:24–42. https://doi.org/10.1016/j.jmbbm.2013.08.022

Shafieian M, Darvish KK, Stone JR (2009) Changes to the viscoelastic properties of brain tissue after traumatic axonal injury. J Biomech 42:2136–2142. https://doi.org/10.1016/j.jbiomech.2009.05.041

Shreiber DI, Hao H, Elias RAI (2009) Probing the influence of myelin and glia on the tensile properties of the spinal cord. Biomech Model Mechanobiol 8:311–321. https://doi.org/10.1007/s10237-008-0137-y

van Dommelen JAW, van der Sande TPJ, Hrapko M, Peters GWM (2010) Mechanical properties of brain tissue by indentation: interregional variation. J Mech Behav Biomed Mater 3:158–166. https://doi.org/10.1016/j.jmbbm.2009.09.001

Velardi F, Fraternali F, Angelillo M (2006) Anisotropic constitutive equations and experimental tensile behavior of brain tissue. Biomech Model Mechanobiol 5:53–61. https://doi.org/10.1007/s10237-005-0007-9

Weickenmeier J, de Rooij R, Budday S et al (2017) The mechanical importance of myelination in the central nervous system. J Mech Behav Biomed Mater 76:119–124. https://doi.org/10.1016/j.jmbbm.2017.04.017

Witek-Krowiak A, Chojnacka K, Podstawczyk D et al (2014) Application of response surface methodology and artificial neural network methods in modelling and optimization of biosorption process. Bioresour Technol 160:150–160. https://doi.org/10.1016/j.biortech.2014.01.021

Yousefsani SA, Farahmand F, Shamloo A (2018a) A three-dimensional micromechanical model of brain white matter with histology-informed probabilistic distribution of axonal fibers. J Mech Behav Biomed Mater 88:288–295. https://doi.org/10.1016/j.jmbbm.2018.08.042

Yousefsani SA, Shamloo A, Farahmand F (2018b) Micromechanics of brain white matter tissue: a fiber-reinforced hyperelastic model using embedded element technique. J Mech Behav Biomed Mater 80:194–202. https://doi.org/10.1016/j.jmbbm.2018.02.002

Yousefsani SA, Shamloo A, Farahmand F (2020) Nonlinear mechanics of soft composites: hyperelastic characterization of white matter tissue components. Biomech Model Mechanobiol. https://doi.org/10.1007/s10237-019-01275-6

Zhang J, Green MA, Sinkus R, Bilston LE (2011) Viscoelastic properties of human cerebellum using magnetic resonance elastography. J Biomech 44:1909–1913. https://doi.org/10.1016/j.jbiomech.2011.04.034

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest concerning the contents of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Hyperelastic models

The plots of normalized Cauchy stress (i.e., the Cauchy stress divided by its corresponding maximum value at the maximum stretch level) obtained using the Ogden hyperelastic model and its special case, the neo-Hookean model with α = 2, are compared in Fig.

Normalized Cauchy stress variations obtained by Ogden and neo-Hookean hyperelastic models in comparison with the experimental data reported in Labus and Puttlitz (2016a) under uniaxial and biaxial tension in the axonal and transverse directions

7 with the experimental data (Labus and Puttlitz 2016a) in both the axial and transverse directions under uniaxial and equibiaxial tensile loadings. It is clear that the simple neo-Hookean model cannot capture the stiffening behavior of the WM tissue at larger deformations.

1.2 Statistical analyses

The normal probability, histogram, and versus fits and orders diagrams for three objective functions \({\text{OBJ}}_{{\text{U||}}}\), \({\text{OBJ}}_{{{\text{U}} \bot }}\), and \({\text{OBJ}}_{{\text{B}}}\) at the first iteration are shown in Fig.

8.

The coefficient of determination (R2) is a measure of proportional variation of the estimated stress values that are predictable from the experimental stress values and is defined as:

where n is the number of divisions of the stretch range, and

Normalized root-mean-square error (NRMSE) is a measure of normalized differences between the estimated stress values predicted by the model and the experimental stress values and is defined as:

1.3 Finite element micromechanical model—FEMM

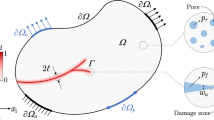

The present FEMM is a three-dimensional RVE consisting of two sections including cylindrical axonal fibers of identical caliber of 0.5 μm uniformly distributed within the hollowed ECM section forming a unidirectional composite tissue with the fiber volume fraction of \(\varphi \approx 32\%\), as depicted in Fig.

9.

These sections are completely tied together with coupled displacements at the commonly shared faces forming an affine boundary condition. Both components are assigned incompressible Ogden hyperelastic material models with different constants set to the optimum solutions obtained by the RSM optimizer at the last iteration. In addition, the geometry is entirely meshed by C3D8RH elements, the 8-node linear brick cubic elements with reduced integration and hybrid formulation considering the incompressibility condition. The analysis type is general static, and nonlinear geometry is available. Comprehensive studies on the mesh refinement and RVE edge sizes and independency of results are available in Yousefsani et al. (2018b).

Considering that repetition of the RVE along the main axes of the coordinate system shown in Fig. 9 must be able to mimic the entire tissue structure at macroscale, different sets of linear algebraic equations, known as the periodic boundary conditions (PBC), should be imposed to the paired boundary nodes of the opposite faces, edges, and corners of the RVE in order to couple the corresponding degrees of freedom and satisfy the conditions of deformation and orientation compatibility. General form of these equations is written as:

where u or uj is the displacement vector of nodes on paired boundaries, \({\mathbf{u}}^{i} = u_{j}^{i} = \overline{F}_{ij} L_{j}\) stands for the displacements of the dummy nodes defined on the RVE boundaries for the application of external loads, Lj is the RVE edge length in j direction, and \(\overline{F}_{ij} = {{\partial x_{i} } \mathord{\left/ {\vphantom {{\partial x_{i} } {\partial X_{j} }}} \right. \kern-\nulldelimiterspace} {\partial X_{j} }}\) represents the deformation gradient tensor with x and X indicating the current (deformed) and reference (undeformed) configurations, respectively. For further details, the interested readers are referred to Karami et al. (2009), Jiménez (2014), and Yousefsani et al. (2018a). It is noteworthy that at each increment of simulation, the strain energy density and volume of each element (which is constant due to incompressibility) were found by post processing the simulation results reports. The total strain energy of the RVE model was calculated by multiplying the strain energy density of each element by its volume and summation over the entire meshed domain. The strain energy density of the RVE then was calculated by dividing the total strain energy by its total volume.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yousefsani, S.A., Karimi, M.Z.V. Bidirectional hyperelastic characterization of brain white matter tissue. Biomech Model Mechanobiol 22, 495–513 (2023). https://doi.org/10.1007/s10237-022-01659-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10237-022-01659-1