Abstract

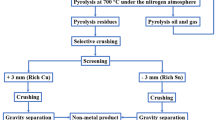

Waste printed circuit boards contain valuable metals such as Au, Pd, Ag, and Cu that can be reutilized and harmful elements such as Pb, Br, and Cr that must be removed from the viewpoint of environmental conservation. In this research, we examined a method that separates the materials from printed circuit boards contained in discarded personal computers. After cutting the printed circuit boards to a size of 20 × 20 mm, they were heated at 873 K under an Ar atmosphere to remove organic resins containing elements such as C, H, and N. After heat treatment, the printed circuit boards were crushed using a planetary ball mill and the pulverized powders were filtered. The fraction with a granularity of greater than 250 μm was separated into magnetic and nonmagnetic materials by a magnetic field. Because the fraction with a granularity of less than 250 μm contained 39 mass% of C, it was heated at 1273 K in an atmosphere of 95% Ar and 5% O2 to allow carbon combustion to take place, followed by metal reduction processing at the same temperature in an atmosphere of 97% Ar and 3% H2. The basicity of the resulting powder was adjusted and the powder was heated at 1773 K under an Ar atmosphere. The proposed method separated the slag and metal, and 80% of the valuable metals contained in printed circuit boards could be collected.

Similar content being viewed by others

References

JEITA Report (2004) Recovery, processing and recycling for IT products (in Japanese). JEITA, Tokyo

Hino T, Narahara D, Agawa R, Tsugita Y, Nishida M, Araki T (2003) Pulverization of waste printed circuit boards. J Mat Cycles Waste Manag 5:137–142

Sakai S, Hirai Y, Aizawa H, Ota S, Muroishi Y (2006) Emission inventory of DBDE in Japan. J Mater Cycles Waste Manag 8:56–62

Oguchi M, Kameya T, Tazaki T, Tamai N, Tanigawa N (2006) Estimation of lifetime distributions and waste numbers of 23 types of electrical and electronic equipment (in Japanese). J Jpn Soc Waste Manag Experts 17(1):50–60

Davenport WGL, King M, Schelesinger M, Biswas AK (2002) Extractive metallurgy of copper. Pergamon, Oxford, pp 57–70

Hagelüken C (2006) Recycling of electronic scrap at Umicore’s integrated metals smelter and refinery. World Metall 59:152–161

Hagelüken C (2006) Improving metal returns and eco-efficiency in electronics recycling. In: Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment. May 8–11, 2006, San Francisco, pp 218–223

Eriksson G, Pelton AD (1993) Critical evaluation and optimization of the thermodynamic properties and phase diagrams of the CaO-Al2O3, Al2O3-SiO2, and CaO-Al2O3-SiO2 systems. Metall Trans B 24:807–816

London Metal Exchange (accessed on Nov. 1, 2007) Prices for Cu and Ni traded on the Exchange. http://www.lme.com/

Sangyo Press Co., Ltd. (accessed on Nov. 1, 2007) Market price for ferrous scrap. http://www.japanmetalbulletin.com/

New York Mercantile Exchange (accessed on Nov. 1, 2007) Market prices for Au, Ag, and Pd. http://www.nymex.com/

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hino, T., Agawa, R., Moriya, Y. et al. Techniques to separate metal from waste printed circuit boards from discarded personal computers. J Mater Cycles Waste Manag 11, 42–54 (2009). https://doi.org/10.1007/s10163-008-0218-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-008-0218-0