Abstract

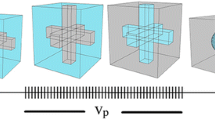

Blend based polymer nanocomposites, comprising Janus nanoparticles at their polymer/polymer interface, were analytically/experimentally evaluated. The modeling procedure was performed in two stages: first, modeling of polymer/polymer interface region comprising Janus nanoparticles and second, modeling of the entire systems as a function of the variation of the blend morphology. In the first stage, the modeling procedure was performed based on the development of the model proposed by Ji et al. and in the second stage, the fundamental of Kolarik’s model was used in order to propose a developed and more practical model. It was shown that Janus nanoparticles may form dual polymer/particle interphase at polymer/polymer interface which can drastically affect the final mechanical properties of the system. Comparing the results of tensile tests imposed on different prepared samples with the predictions of the model proved its accuracy and reliability (error < 9%).

Similar content being viewed by others

References

Fathi, A.; Lee, S.; Breen, A.; Shirazi, A. N.; Valtchev, P.; Dehghani, F. Enhancing the mechanical properties and physical stability of biomimetic polymer hydrogels for micro–patterning and tissue engineering applications. Eur. Polym. J. 2014, 59, 161–170.

Minaei–Zaim, M.; Ghasemi, I.; Karrabi, M.; Azizi, H. Effect of injection molding parameters on properties of cross–linked low-density polyethylene/ethylene vinyl acetate/organoclay nanocomposite foams. Iran Polym. J. 2012, 21, 537–546.

Shaw, M. T. in Preparation of blends. in polymer blends and mixtures. Walsh, D. J.; Higgins, J. S.; Maconnachie, A., Eds. Springer Netherlands: Dordrecht, 1985, p57–6.

Galloway, J. A.; Macosko, C. W. Comparison of methods for the detection of cocontinuity in poly(ethylene oxide)/polystyrene blends. Polym. Eng. Sci. 2004, 44, 714–727.

Zaikov, G. E.; Bazylyak, L. I.; Haghi, A. K. in Functional polymer blends and nanocomposites: a practical engineering approach. Apple Academic Press, 2014

Miles, I. S.; Zurek, A. Preparation, structure, and properties of two–phase co–continuous polymer blends. Polym. Eng. Sci. 1988, 28, 796–805.

Pivsa–Art, W.; Chaiyasat, A.; Pivsa–Art, S.; Yamane, H.; Ohara, H. Preparation of polymer blends between poly(lactic acid) and poly(butylene adipate–co–terephthalate) and biodegradable polymers as compatibilizers. Energy Procedia 2013, 34, 549–554.

Khaparde, D. Preparation and prediction of physical properties of cellulose acetate and polyamide polymer blend. Carbohydr. Polym. 2017, 173, 338–343.

Lepcio, P.; Ondreas, F.; Zarybnicka, K.; Zboncak, M.; Caha, O.; Jancar, J. Bulk polymer nanocomposites with preparation protocol governed nanostructure: the origin and properties of aggregates and polymer bound clusters. Soft Matter 2018, 14, 2094–2103.

Ucankus, G.; Ercan, M.; Uzunoglu, D.; Culha, M., 1–Methods for preparation of nanocomposites in environmental remediation A2–Hussain, Chaudhery Mustansar. In New polymer nanocomposites for environmental remediation, Mishra, A. K., Ed. Elsevier, 2018, pp 1–2.

Mittal, V. in Polymer nanotube nanocomposites: synthesis, properties, and applications. Wiley, 2010

Koo, J. H. in Fundamentals, properties, and applications of polymer nanocomposites. Cambridge University Press, 2016

Thomas, S.; Grohens, Y.; Jyotishkumar, P. in Characterization of polymer blends: miscibility, morphology and interfaces. Wiley, 2014

Isayev, A. I. in Encyclopedia of polymer blends: volume 1: Fundamentals. John Wiley & Sons, 2010

Bai, L.; He, S.; Fruehwirth, J. W.; Stein, A.; Macosko, C. W.; Cheng, X. Localizing graphene at the interface of cocontinuous polymer blends: Morphology, rheology, and conductivity of cocontinuous conductive polymer composites. J. Rheol. 2017, 61, 575–587.

Landel, R. F.; Nielsen, L. E. in Mechanical properties of polymers and composites, Second Edition. Taylor & Francis, 1993

Chiu, F. C.; Yen, H. Z.; Lee, C. E. Characterization of PP/HDPE blend–based nanocomposites using different maleated polyolefins as compatibilizers. Polym. Test. 2010, 29, 397–406.

Naffakh, M.; Diez–Pascual, A. M.; Marco, C. Polymer blend nanocomposites based on poly(L–lactic acid), polypropylene and WS2 inorganic nanoltubes. RSC Adv. 2016, 6, 40033–40044.

Baudouin, A. C.; Devaux, J.; Bailly, C. Localization of carbon nanotubes at the interface in blends of polyamide and ethyleneacrylate copolymer. Polymer 2010, 51, 1341–1354.

Sharifzadeh, E.; Salami–Kalajahi, M.; Hosseini, M. S.; Aghjeh, M. K. R. Synthesis of silica Janus nanoparticles by buoyancy effect–induced desymmetrization process and their placement at the PS/PMMA interface. Colloid. Polym. Sci. 2017, 295, 25–36.

Bryson, K. C.; Löbling, T. I.; Müller, A. H. E.; Russell, T. P.; Hayward, R. C. Using Janus nanoparticles to trap polymer blend morphologies during solvent–evaporation–induced demixing. Macromolecules 2015, 48, 4220–4227.

Paunov, V. N.; Cayre, O. J. Supraparticles and "Janus" particles fabricated by replication of particle monolayers at liquid surfaces using a gel trapping technique. Adv. Mater. 2004, 16, 788–791.

Lv, W.; Lee, K. J.; Li, J.; Park, T.–H.; Hwang, S.; Hart, A. J.; Zhang, F.; Lahann, J. Anisotropic Janus catalysts for spatially controlled chemical reactions. Small 2012, 8, 3116–3122.

Roh, K. H.; Martin, D. C.; Lahann, J. Biphasic Janus particles with nanoscale anisotropy. Nat. Mater. 2005, 4, 759.

Giermanska–Kahn, J.; Laine, V.; Arditty, S.; Schmitt, V.; Leal–Calderon, F. Particle–stabilized emulsions comprised of solid droplets. Langmuir 2005, 21, 4316–4323.

Fernandez–Rodriguez, M. A.; Rodriguez–Valverde, M. A.; Cabrerizo–Vilchez, M. A.; Hidalgo–Alvarez, R. Surface activity of Janus particles adsorbed at fluid–fluid interfaces: Theoretical and experimental aspects. Adv. Colloid Interface Sci. 2016, 233,240–254.

Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocompositesA review. Prog. Polym. Sci. 2013, 38, 1232–1261.

Mahdavi, M.; Ahmad, M.; Haron, M.; Namvar, F.; Nadi, B.; Rahman, M.; Amin, J. Synthesis, surface modification and characterisation of biocompatible magnetic iron oxide nanoparticles for biomedical applications. Molecules 2013, 18, 7533–7548.

Taguet, A.; Cassagnau, P.; Lopez–Cuesta, J. M. Structuration, selective dispersion and compatibilizing effect of (nano)fillers in polymer blends. Prog. Polym. Sci. 2014, 39,1526–1563.

Sharifzadeh, E.; Ghasemi, I.; Karrabi, M.; Azizi, H. A new approach in modeling of mechanical properties of binary phase polymeric blends. Iran Polym. J. 2014, 23, 525–530.

Sharifzadeh, E.; Ghasemi, I.; Karrabi, M.; Azizi, H. A new approach in modeling of mechanical properties of nanocomposites: effect of interface region and random orientation. Iran Polym. J. 2014, 23, 835–845.

Sharifzadeh, E.; Ghasemi, I.; Safajou–Jahankhanemlou, M. Modulus prediction of binary phase polymeric blends using symmetrical approximation systems as a new approach. Iran Polym. J. 2015, 24, 735–746.

Zare, Y. Modeling the strength and thickness of the interphase in polymer nanocomposite reinforced with spherical nanoparticles by a coupling methodology. J. Colloid Interface Sci. 2016, 465, 342–346.

Zare, Y. Modeling of tensile modulus in polymer/carbon nanotubes (CNT) nanocomposites. Synth. Met. 2015, 202, 68–72.

Zare, Y.; Rhee, K. Y.; Park, S. J. Modeling of tensile strength in polymer particulate nanocomposites based on material and interphase properties. J. Appl. Polym. Sci. 2017,134, 44869.

Bao, W. S.; Meguid, S. A.; Zhu, Z. H.; Meguid, M. J. Modeling electrical conductivities of nanocomposites with aligned carbon nanotubes. Nanotechnology 2011, 22, 485704.

Zare, Y. Modeling approach for tensile strength of interphase layers in polymer nanocomposites. J. Colloid Interface Sci. 2016, 471, 89–93.

Sharifzadeh, E.; Ghasemi, I.; Qarebagh, A. N. Modeling of blend–based polymer nanocomposites using a knotted approximation of Young's modulus. Iran Polym. J. 2015, 24, 1039–1047.

Mortazavi, S.; Ghasemi, I.; Oromiehie, A. Prediction of tensile modulus of nanocomposites based on polymeric blends. Iran Polym. J. 2013, 22, 437–445.

Dong, B.; Huang, Z.; Chen, H.; Yan, L. T. Chain–stiffness–induced entropy effects mediate interfacial assembly of Janus nanoparticles in block copolymers: from interfacial nanostructures to optical responses. Macromolecules 2015, 48, 5385–5393.

Zhu, G.; Huang, Z.; Xu, Z.; Yan, L. T. Tailoring interfacial nanoparticle organization through entropy. Acc. Chem. Res. 2018, 51, 900–909.

Chen, P.; Yang, Y.; Dong, B.; Huang, Z.; Zhu, G.; Cao, Y.; Yan, L. T. Polymerization–induced interfacial self–assembly of Janus nanoparticles in block copolymers: reaction–mediated entropy effects, diffusion dynamics, and tailorable micromechanical behaviors. Macromolecules 2017, 50, 2078–2091.

Ji, X. L.; Jing, J. K.; Jiang, W.; Jiang, B. Z. Tensile modulus of polymer nanocomposites. Polym. Eng. Sci. 2002, 42, 983–993.

Wang, J. F.; Carson, J. K.; North, M. F.; Cleland, D. J. A knotted and interconnected skeleton structural model for predicting Young's modulus of binary phase polymer blends. Polym. Eng. Sci. 2010, 50, 643–651.

Kolarík, J. Three–dimensional models for predicting the modulus and yield strength of polymer blends, foams, and particulate composites. Polym. Compos. 1997, 18, 433–441.

Sharifzadeh, E.; Salami–Kalajahi, M.; Hosseini, M. S.; Aghjeh, M. K. R. A temperature–controlled method to produce Janus nanoparticles using high internal interface systems:Experimental and theoretical approaches. Colloid Surface A 2016, 506, 56–62.

Sharifzadeh, E.; Salami–Kalajahi, M.; Salami Hosseini, M.; Razavi Aghjeh, M. K.; Najafi, S.; Jannati, R.; Hatef, Z. Defining the characteristics of spherical Janus particles by investigating the behavior of their corresponding particles at the oil/water interface in a Pickering emulsion. J. Dispersion Sci. Technol. 2017, 38, 985–991.

Mekhilef, N.; Verhoogt, H. Phase inversion and dual–phase continuity in polymer blends: theoretical predictions and experimental results. Polymer 1996, 37, 4069–4077.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

10118_2019_2178_MOESM1_ESM.pdf

Modeling of the Mechanical Properties of Blend Based Polymer Nanocomposites Considering the Effects of Janus Nanoparticles on Polymer/Polymer Interface

Rights and permissions

About this article

Cite this article

Sharifzadeh, E. Modeling of the Mechanical Properties of Blend Based Polymer Nanocomposites Considering the Effects of Janus Nanoparticles on Polymer/Polymer Interface. Chin J Polym Sci 37, 164–177 (2019). https://doi.org/10.1007/s10118-019-2178-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-019-2178-3