Abstract

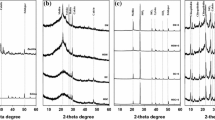

The beneficiation of sludge from pulp and paper mills to produce high-value products such as crystalline nanocellulose will alleviate the challenges associated with conventional methods of sludge disposal, such as landfilling and incineration. In addition, the use of sludge will reduce the consumption of fresh raw materials in the synthesis of nanocellulose which is usually produced from high-purity cellulose pulps. In this study, fibres were cleaned and separated from sludge and then converted to crystalline nanocellulose using ammonium persulphate under optimised oxidative conditions. To extend potential applications of the crystalline nanocellulose produced, the crystalline nanocellulose was functionalised with zinc oxide, silver and hydroxyapatite to prepare crystalline nanocellulose-zinc oxide, crystalline nanocellulose-silver and crystalline nanocellulose-hydroxyapatite nano- and micro-composites powders using the sol–gel process. Transmission electron microscopy, field-emission scanning electron microscopy, X-ray diffraction and thermo-gravimetric analysis were used to investigate the properties of crystalline nanocellulose and functionalised crystalline nanocellulose. The transmission electron microscope and field-emission scanning electron microscope coupled with energy-dispersive X-ray spectroscopy confirmed the synthesis of crystalline nanocellulose, and inorganic nanoparticles. Functionalised samples (crystalline nanocellulose-zinc oxide, crystalline nanocellulose-silver and crystalline nanocellulose-hydroxyapatite) showed better thermal stability than pure crystalline nanocellulose. This implies that the modified inorganic crystalline nanocellulose composites could be used in applications where thermal stability is desirable. The cost of production is economically viable as the raw material cost is cheaper compared to the use of wood pulp.

Similar content being viewed by others

References

Alamri HL, Low IM (2010) Characterisation and properties of recycled cellulose fibre- reinforced epoxy-hybrid clay nanocomposites. Mater Sci Forum 654–656:2624–2627. https://doi.org/10.4028/www.scientific.net/MSF.654-656.2624

Azizi S, Ahmad M, Mahdavi M, Abdolmohammadi S (2013) Preparation, characterisation, and antimicrobial activities of ZnO nanoparticles/cellulose nanocrystal nanocomposites. BioResources 8:1841–1851

Bahar KI, Zeynep C, Orhan I (2011) Pollution prevention in the pulp and paper industries. Environ Manag Pract. https://doi.org/10.5772/23709

Bajpai P (2012) Management/utilisation of wastewater treatment sludges. In: Biotechnology for pulp and paper processing. Springer, New York, pp 349–373. https://doi.org/10.1007/978-1-4614-1409-4_18

Bajpai P (2015) Management of pulp and paper mill waste. Springer, Basel

Boshoff S, Gottumukkala LD, van Rensburg E, Görgens J (2016) Paper sludge (PS) to bioethanol: evaluation of virgin and recycle mill sludge for low enzyme, high-solids fermentation. Bioresour Technol 203:103–111. https://doi.org/10.1016/j.biortech.2015.12.028

Bouyer E, Gitzhofer F, Boulos MI (2000) Morphological study of hydroxyapatite nanocrystal suspension. J Mater Sci Mater Med 11:523–531. https://doi.org/10.1023/a:1008918110156

Darroudi M, Ahmad MB, Abdullah AH, Ibrahim NA, Shameli K (2010) Effect of accelerator in green synthesis of silver nanoparticles. Int J Mol Sci 11:3898

Department of Environmental Affairs and Tourism (DEAT) (2000) White paper on integrated pollution and waste management for South Africa: a policy on pollution prevention, waste minimisation, impact management and remediation. South African Government Gazette 20978, vol 417, pp 1–79

Fallah MH, Fallah SA, Zanjanchi MA (2011) Synthesis and characterisation of nano-sized zinc oxide coating on cellulosic fibers: photoactivity and flame-retardancy study. Chin J Chem 29:1239–1245. https://doi.org/10.1002/cjoc.201190230

Firoz Babu K, Dhandapani P, Maruthamuthu S, Anbu Kulandainathan M (2012) One pot synthesis of polypyrrole silver nanocomposite on cotton fabrics for multifunctional property. Carbohyd Polym 90:1557–1563. https://doi.org/10.1016/j.carbpol.2012.07.030

Gallardo F, Bravo C, Briceño G, Diez MC (2010) Use of sludge from kraft mill wastewater treatment as improver of volcanic soils: effect on soil biological parameters. Revista de la ciencia del suelo y nutrición vegetal 10:48–61

Hanemann T, Szabó DV (2010) Polymer-nanoparticle composites: from synthesis to modern applications. Materials 3:3468–3517

Herrera MA, Mathew AP, Oksman K (2012) Characterisation of cellulose nanowhiskers: a comparison of two industrial bio-residues. IOP Publishing Conf. Ser. Mater Sci Eng 31:012006

Heyman A, Lapidot S, Meirovitch S, Nevo Y, Rivkin A, Shoseyov O (2012) Method for production of cellulose nano crystals from cellulose-containing waste materials. Google Patents

Jonoobi M, Mathew AP, Oksman K (2012) Producing low-cost cellulose nanofibre from sludge as new source of raw materials. Ind Crop Prod 40:232–238. https://doi.org/10.1016/j.indcrop.2012.03.018

Jorfi M, Foster EJ (2015) Recent advances in nanocellulose for biomedical applications. J Appl Polym Sci. https://doi.org/10.1002/app.41719

Khan A, Khan RA, Salmieri S, Le Tien C, Riedl B, Bouchard J, Chauve G, Tan V, Kamal MR, Lacroix M (2012) Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydrate polymers 90(4):1601–1608

Kim H, Pramanik NC, Ahn BY, Seok SI (2006) Preparation of inorganic–organic hybrid titania sol–gel nanocomposite films, and their dielectric properties. Phys Status Solidi (A) 203:1962–1970. https://doi.org/10.1002/pssa.200521234

Krigstin SG (2008) Characterisation of recycled paper mill sludge and evaluation of potential applications. Ph.D. thesis, University of Toronto (Canada)

Leal GF, Ramos LA, Barrett DH, Curvelo AAS, Rodella CB (2015) A thermogravimetric analysis (TGA) method to determine the catalytic conversion of cellulose from carbon-supported hydrogenolysis process. Thermochim Acta 616:9–13. https://doi.org/10.1016/j.tca.2015.07.017

Lekha P, Andrew JE, Gibril M, Sithole B (2017) Pulp and Paper mill sludge: a potential resource for producing high-value products. TAPPSA 1:16–19

Likon M, Trebše P (2012) Recent advances in paper mill sludge management. In: Show K-Y, Guo X (eds) Industrial waste. InTech, Osaka. https://doi.org/10.5772/37043

Lin N, Dufresne A (2014) Nanocellulose in biomedicine: current status and future prospect. Eur Polym J 59:302–325. https://doi.org/10.1016/j.eurpolymj.2014.07.025

Mochochoko T, Oluwafemi OS, Jumbam DN, Songca SP (2013) Green synthesis of silver nanoparticles using cellulose extracted from an aquatic weed; water hyacinth. Carbohydr Polym 98(1):290–294. https://doi.org/10.1016/j.carbpol.2013.05.038

Monte MC, Fuente E, Blanco A, Negro C (2009) Waste management from pulp and paper production in the European Union. Waste Manag 29:293–308. https://doi.org/10.1016/j.wasman.2008.02.002

Mott D, Galkowski J, Wang L, Luo J, Zhong C-J (2007) Synthesis of size-controlled and shaped copper nanoparticles. Langmuir 23:5740–5745. https://doi.org/10.1021/la0635092

Nadanathangam V, Sampath K, Kathe AA, Varadarajan PV, Virendra P (2006) Functional finishing of cotton fabrics using zinc oxide–soluble starch nanocomposites. Nanotechnology 17:5087

Nevo Y, Peer N, Yochelis S, Igbaria M, Meirovitch S, Shoseyov O, Paltiel Y (2015) Nano bio optically tunable composite nanocrystalline cellulose films. RSC Advances 5(10):7713–7719

Ngadi N, Lani NS (2014) Extraction and characterisation of cellulose from empty fruit bunch (EFB) fiber. Jurnal Teknologi (Sciences and Engineering) 68:35–39

Ochoa de Alda JAG (2008) Feasibility of recycling pulp and paper mill sludge in the paper and board industries. Resour Conserv Recycl 52:965–972. https://doi.org/10.1016/j.resconrec.2008.02.005

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Pinto RJB, Neves MC, Neto CP, Trindade T (2012) Composites of cellulose and metal nanoparticles. Nanocompos—New Trends Dev. https://doi.org/10.5772/50553

Sadanand V, Rajini N, Satyanarayana B, Rajulu AV (2016) Preparation and properties of cellulose/silver nanoparticle composites with in situ-generated silver nanoparticles using Ocimum sanctum leaf extract. Int J Polym Anal Ch 21:408–416. https://doi.org/10.1080/1023666X.2016.1161100

Salas C, Nypelö T, Rodriguez-Abreu C, Carrillo C, Rojas OJ (2014) Nanocellulose properties and applications in colloids and interfaces. Curr Opin Colloid Interface Sci 19:383–396. https://doi.org/10.1016/j.cocis.2014.10.003

Selvam S, Rajiv Gandhi R, Suresh J, Gowri S, Ravikumar S, Sundrarajan M (2012) Antibacterial effect of novel synthesised sulfated β-cyclodextrin crosslinked cotton fabric and its improved antibacterial activities with ZnO, TiO2 and Ag nanoparticles coating. Int J Pharmaceut 434:366–374. https://doi.org/10.1016/j.ijpharm.2012.04.069

Shen Z, Han G, Liu C, Wang X, Sun R (2016) Green synthesis of silver nanoparticles with bagasse for colorimetric detection of cysteine in serum samples. J Alloys Compd 686:82–89. https://doi.org/10.1016/j.jallcom.2016.05.348

Shoseyov O, Paltiel Y, Yochelis S, Baruch-Sharon S, Nevo Y (2013) Light spectrum tunable nanocomposites. Google Patents

Stevanovic A, Büttner M, Zhang Z, Yates JT (2012) Photoluminescence of TiO2: effect of UV light and adsorbed molecules on surface band structure. J Am Chem Soc 134:324–332. https://doi.org/10.1021/ja2072737

TAPPI method Tc (1999) Carbohydrate composition of extractive free wood and wood pulp by gas–liquid chromatography. TAPPI Press, Atlanta

Vecbiskena L, Rozenberga L (2017) Nanocelluloses obtained by ammonium persulphate (APS) oxidation of bleached kraft pulp (BKP) and bacterial cellulose (BC) and their application in biocomposite films together with chitosan. Holzforschung. https://doi.org/10.1515/hf-2016-0187

Wan YZ, Hong L, Jia SR, Huang Y, Zhu Y, Wang YL, Jiang HJ (2006) Synthesis and characterisation of hydroxyapatite–bacterial cellulose nanocomposites. Compos Sci Technol 66:1825–1832. https://doi.org/10.1016/j.compscitech.2005.11.027

Acknowledgements

The authors are thankful to the technical staff at the BIDF for chemical characterisation of the sludge samples and sludge pre-treatment, the Microanalysis and Microscopy unit at UKZN for the use of their microscopes, as well as the CSIR and the Department of Science Technology (DST) Waste Roadmap project for funding the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gibril, M.E., Lekha, P., Andrew, J. et al. Beneficiation of pulp and paper mill sludge: production and characterisation of functionalised crystalline nanocellulose. Clean Techn Environ Policy 20, 1835–1845 (2018). https://doi.org/10.1007/s10098-018-1578-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-018-1578-3