Abstract

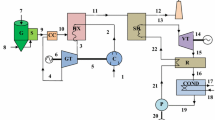

Techno-economic performance analysis of a biomass-fired combined cycle plant, employing a topping air turbine (AT) cycle and a bottoming steam turbine cycle, is reported in this paper. The net power output is 500 kWe, the AT producing 350 kWe and the ST producing the rest. Biomass (saw dust) is directly fired in a biomass combustor-heat exchanger (BCHX) duplex unit which supplies heat to the topping cycle. Influences of major plant parameters on the thermo-economic performance of the plant are analysed. Overall efficiency is found to maximise at topping cycle pressure ratio of 4. Higher TIT results in better energetic performance, while higher hot end temperature difference of the BCHX unit lowers the plant efficiency. Thermo-economic analysis reveals that the lowest unit cost of electricity (UCOE) of about 0.12 $/kWh could be achieved for the plant, while still giving an overall efficiency of about 48 %. Based on minimum UCOE, the payback period is estimated to be about 6 years with 50 % capital subsidy and about 13 years with no capital subsidy.

Similar content being viewed by others

Abbreviations

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- \(\dot{n}\) :

-

Mole flow rate (kmol/s)

- p :

-

Pressure (bar)

- T :

-

Temperature (K/°C)

- r p :

-

Pressure ratio (−)

- m :

-

Fraction of capital cost (%)

- P :

-

Total power output (kW)

- W :

-

Work (kW)

- CUF:

-

Capital utilisation factor (%)

- UCOE:

-

Unit cost of electricity ($/kWh)

- SBC:

-

Specific biomass consumption (kg/kWh)

- η :

-

Efficiency-energy conversion (%)

- ξ :

-

Specific CO2 emission (kg/kWh)

- BFCC:

-

Biomass-fired combined cycle

- BCHX:

-

Biomass combustor-heat exchanger duplex unit

- EFGT:

-

Externally fired gas turbine

- AT:

-

Air turbine

- ST:

-

Steam turbine

- GT:

-

Gas turbine

- CC:

-

Combustor

- TIT:

-

Turbine inlet temperature

- DN:

-

Distribution network

- CW:

-

Civil works

- F:

-

Fuel

- HETD:

-

Hot end temperature difference

- OM:

-

Operation and Maintenance

- LMTD:

-

Log mean temperature difference

- WB:

-

Wet bulb

References

Al-attab KA, Zainal ZA (2010) Turbine startup methods for externally fired micro air turbine (EFMAT) system using biomass fuels. Appl Energy 87:1336–1341

Athari H, Soltani S, Mahamoudi SMS, Rosen MA, Morosuk T (2014) Exergoeconomic analysis of a biomass post-firing combined-cycle power plant. Energy 77:553–561

Bejan A, Tsatsaronis G, Moran M (1996) Energy design and optimization. Wiley, New York

Brown D, Gassner M, Fuchino T, Maréchal F (2009) Thermo-economic analysis for the optimal conceptual design of biomass gasification energy conversion systems. Appl Ther Eng 29(11–12):2137–2152

Buragohain B, Mahanta P, Moholkar VS (2010) Biomass gasification for decentralized power generation: the Indian perspective. Renew Sustain Energy Rev 14(1):73–92

Camporeale SM, Pantaleo AM, Ciliberti PD, Fortunato B (2015) Cycle configuration analysis and techno-economic sensitivity of biomass externally fired gas turbine with bottoming ORC. Energy Convers Manage 105:1239–1250

Chakma S, Ranjan A, Choudhury HA, Dikshit PK, Moholkar VS (2016) Bioenergy from rice crop residues: role in developing economies. Clean Technol Environ Policy 18:373–394

Datta A, Ganguli R, Sarkar L (2010) Energy and exergy analyses of an externally fired air turbine (EGFT), cycle integrated with biomass gasifier for distributed power generation. Energy 35:341–350

Franco A, Giannini N (2005) Perspectives for the use of biomass as fuel in combined cycle power plants. Int J Therm Sci 44:163–177

Jana K, De S (2015) Polygeneration performance assessments: multi-dimensional viewpoint. Clean Technol Environ Policy 17:1547–1561

Kautz M, Hansen U (2007) The externally-fired gas-turbine (EFAT-Cycle) for decentralized use of biomass. Appl Energy 84:795–805

Keche AJ, Gaddale APR, Tated RG (2015) Simulation of biomass gasification in downdraft gasifier for different biomass fuels using ASPEN PLUS. Clean Technol Environ Policy 17:465–473

Mondal P, Ghosh S (2013) Comparative performance of two biomass based combined cycle plant, one with fired heat exchanger and other with integrated gasification. In: Proceedings of the 22th national and 11th international ISHMT-ASME heat and mass trans conf, Dec 28–31, IIT Kharagpur, India. Paper ID HMTC1300509

Mondal P, Ghosh S (2015) Thermodynamic performance assessment of a bio-gasification based small-scale combined cogeneration plant employing indirectly heated air turbine. Int J Renew Energy Res 5(2):354–366

Mondal P, Ghosh S (2016) Bio-gasification based externally fired combined cogeneration plant: thermo-economic and exergo-economic Analyses. Int J Exergy (in press)

Nouni MR, Mullick SC, Kandpal TC (2007) Biomass gasifier projects for decentralized power supply in India: a financial evaluation. Energy Policy 35(2):1373–1385

Pantaleo AM, Camporeale SM, Shah N (2013) Thermo-economic assessment of externally fired micro-gas turbine fired by natural gas and biomass: applications in Italy. Energy Convers Manage 75:202–213

Rodrigues M, Faaij APC, Walter a (2003) Techno-economic analysis of co-fired biomass integrated gasification/combined cycle systems with inclusion of economies of scale. Energy 28(12):1229–1258

Soltani S, Mahamoudi SMS, Yari M, Morosuk T, Rosen MA, Zare V (2013) A comparative exergoeconomic analysis of two biomass and co-firing combined power plants. Energy Convers Manage 76:83–91

Tripathi AK, Iyer PVR, Kandpalh TC (1997) A financial evaluation of biomass-gasifier-based power generation in India. Bioresour Technol 61:53–59

Tsakomakas NG, Pilavachi PA, Polyzakis AL (2012) An economic comparison assessment of lignite and biomass IGCC power plants. Appl Therm Eng 38(5):26–30

Vera D, Jurado F, Caprio J (2011a) Study of a downdraft gasifier and externally fired gas turbine for olive industry wastes. Fuel Process Technol 92:1970–1979

Vera D, Jurado F, de Mena B, Schories G (2011b) Comparison between externally fired air turbine and gasifier-air turbine system for the olive oil industry. Energy 36:6720–6730

Website: http://products.asminternational.org/hbk/index.jsp. Website of ASM online products (Accessed on 10 Mar 2016)

Acknowledgments

The first author acknowledges the support provided by the Thermal Simulation and Computation (TSC) Lab at the Mechanical Engineering Department of IIEST, Shibpur for carrying out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mondal, P., Ghosh, S. Techno-economic performance evaluation of a direct biomass-fired combined cycle plant employing air turbine. Clean Techn Environ Policy 19, 427–436 (2017). https://doi.org/10.1007/s10098-016-1228-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1228-6