Abstract

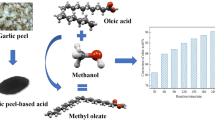

Oxidized and sulfonated-activated carbons (AC) were tested in the catalytic conversion of glycerol by acetalization reactions. The solids were treated with concentrated nitric acid and/or fuming sulfuric acid (AC, AC-N, AC-S, and AC-NS). The presence of sulfur and an increase in the acidity of the solids demonstrate the suitability of the oxidation as well as the sulfonation process, especially in the sample treated with concentrated nitric acid and fuming sulfuric acid (AC-NS). The best catalyst for the reaction of glycerol acetalization with phenylacetaldehyde was AC-NS, with a phenylacetaldehyde conversion of 95 % after 90 min at 383 K and selectivity of 88 and 12 %, respectively, to dioxolane and dioxane. These products can be used as hyacinth fragrance flavoring compounds. Furthermore, a contribution of homogeneous catalysis in these systems was not identified. Thus, we identified a possibility of glycerol conversion, a biodiesel by-product, into value-added products by suitable catalysts produced from activated carbons.

Similar content being viewed by others

References

Agirre I, García I, Requies J, Barrio VL, Güemez MB, Cambra JF, Arias PL (2011) Glycerol acetals, kinetic study of the reaction between glycerol and formaldehyde. Biomass Bioenergy 35:3636–3642. doi:10.1016/j.biombioe.2011.05.008

Aksnes G, Albriktsen P, Juvvik P (1965) Studies of cyclic acetal and ketal isomers of glycerol. Acta Chem Scand 19:920–930. doi:10.3891/acta.chem.scand.19-0920

Amrute AP, Sahoo S, Bordoloi A, Hwang YK, Hwang J-S, Halligudi SB (2009) MoO3/SiO2: an efficient and selective catalyst for the synthesis 1,3-dioxolane and 1,3-dioxane. Catal Commun 10:1404–1409. doi:10.1016/j.catcom.2009.03.007

Balaraju M, Rekha V, Prasad PSS, Devi BLAP, Prasad RBN, Lingaiah N (2009) Influence of solid acids as co-catalysts on glycerol hydrogenolysis to propylene glycol over Ru/C catalysts. Appl Catal A 354:82–87. doi:10.1016/j.apcata.2008.11.010

Bulanov DA, Novokshonova IA, Safronova LP, Ushakov IA, Medvedeva AS (2016) Highly efficient microwave assisted synthesis of polyfunctional 1,3-dioxolanes from γ-hydroxypropynals. Tetrahedron Lett 57:172–176. doi:10.1016/j.tetlet.2015.11.084

Câmara JS, Marques JC, Alves A, Ferreira ACS (2003) Heterocyclic acetals in Madeira wines. Anal Bioanal Chem 375:1221–1224. doi:10.1007/s00216-003-1818-0

Capeletti MR, Balzano L, de la Puente G, Laborde M, Sedran U (2000) Synthesis of acetal (1,1-diethoxyethane) from ethanol and acetaldehyde over acidic catalysts. Appl Catal A 198:L1–L4. doi:10.1016/S0926-860X(99)00502-5

Chapuis C, Jacoby D (2001) Catalysis in the preparation of fragrances and flavours. Appl Catal A 221:93–117. doi:10.1016/S0926-860X(01)00798-0

Chopade SP, Sharma MM (1997) Acetalization of ethylene glycol with formaldehyde using cation-exchange resins as catalysts: batch versus reactive distillation. React Funct Polym 34:37–45. doi:10.1016/S1381-5148(97)00018-7

Climent MJ, Corma A, Velty A (2004) Synthesis of hyacinth, vanilla, and blossom orange fragrances: the benefit of using zeolites and delaminated zeolites as catalysts. Appl Catal A 263:155–161. doi:10.1016/j.apcata.2003.12.007

Corma A, Iborra S, Velty A (2007) Chemical routes for the transformation of biomass into chemicals. Chem Rev 107:2411–2502. doi:10.1021/cr050989d

da Silva CXA, Mota CJA (2011) The influence of impurities on the acid-catalyzed reaction of glycerol with acetone. Biomass Bioenergy 35:3547–3551. doi:10.1016/j.biombioe.2011.05.004

de Araujo Filho CA, Salmi T, Bernas A, Mikkola JP (2013) Kinetic Model for Homogeneously Catalyzed Halogenation of Glycerol. Ind Eng Chem Res 52:1523–1530. doi:10.1021/ie302610v

Dean JA (1999) Binary Azeotropic (Constant-Boiling) Mixtures. In: Perry RH, Green DW (eds) Lange’s handbook of chemistry, 15th edn. McGraw-Hill, New York

Deutsch J, Martin A, Lieske H (2007) Investigations on heterogeneously catalysed condensations of glycerol to cyclic acetals. J Catal 245:428–435. doi:10.1016/j.jcat.2006.11.006

Faria RPV, Pereira CSM, Silva VMTM, Loureiro JM, Rodrigues AE (2013a) Glycerol valorisation as biofuels: selection of a suitable solvent for an innovative process for the synthesis of GEA. Chem Eng J 233:159–167. doi:10.1016/j.cej.2013.08.035

Faria RPV, Pereira CSM, Silva VMTM, Loureiro JM, Rodrigues AE (2013b) Glycerol Valorization as Biofuel: thermodynamic and Kinetic Study of the Acetalization of Glycerol with Acetaldehyde. Ind Eng Chem Res 52:1538–1547. doi:10.1021/ie302935w

Ferreira ACS, Barbe J-C, Bertrand A (2002) Heterocyclic acetals from glycerol and acetaldehyde in Port wines: evolution with aging. J Agric Food Chem 50:2560–2564. doi:10.1021/jf011391j

Frusteri F, Spadaro L, Beatrice C, Guido C (2007) Oxygenated additives production for diesel engine emission improvement. Chem Eng J 134:239–245. doi:10.1016/j.cej.2007.03.042

Galhardo TS, Simone N, Gonçalves M, Figueiredo FCA, Mandelli D, Carvalho WA (2013) Preparation of sulfonated carbons from rice husk and their application in catalytic conversion of glycerol. ACS Sustain Chem Eng 1:1381–1389. doi:10.1021/sc400117t

Gelosa D, Ramaioli M, Valente G, Morbidelli M (2003) Chromatographic reactors: esterification of glycerol with acetic acid using acidic polymeric resins. Ind Eng Chem Res 42:6536–6544. doi:10.1021/ie030292n

Gonçalves M, Souza VC, Galhardo TS, Mantovani M, Figueiredo FCA, Mandelli D, Carvalho WA (2013) Glycerol conversion catalyzed by carbons prepared from agroindustrial wastes. Ind Eng Chem Res 52:2832–2839. doi:10.1021/ie303072d

Gordobil O, Moriana R, Zhang L, Labidi J, Sevastyanova O (2016) Assesment of technical lignins for uses in biofuels and biomaterials: structure-related properties, proximate analysis and chemical modification. Ind Crop Prod 83:155–165. doi:10.1016/j.indcrop.2015.12.048

Gorgulho HF, Mesquita JP, Goncalves F, Pereira MFR, Figueiredo JL (2008) Characterization of the surface chemistry of carbon materials by potentiometric titrations and temperature-programmed desorption. Carbon 46:1544–1555. doi:10.1016/j.carbon.2008.06.045

Güemez MB, Requies J, Agirre I, Arias PL, Barrio VL, Cambra JF (2013) Acetalization reaction between glycerol and n-butyraldehyde using an acidic ion exchange resin. Kinetic modelling. Chem Eng J 228:300–307. doi:10.1016/j.cej.2013.04.107

Huang C-C, Li H-S, Chen C-H (2008) Effect of surface acidic oxides of activated carbon on adsorption of ammonia. J Hazard Mater 159:523–527. doi:10.1016/j.jhazmat.2008.02.051

Hutson N, Yang R (1997) Theoretical basis for the Dubinin-Radushkevitch (D-R) adsorption isotherm equation. Adsorption 3:189–195. doi:10.1007/bf01650130

Jung S-J, Kim S-H, Chung I-M (2015) Comparison of lignin, cellulose, and hemicellulose contents for biofuels utilization among 4 types of lignocellulosic crops. Biomass Bioenergy 83:322–327. doi:10.1016/j.biombioe.2015.10.007

Kaufhold M, El-Chahawi M (1996) Process for preparing acetaldehyde diethyl acetal. Germany Patent 5527969

Khayoon MS, Hameed BH (2011) Acetylation of glycerol to biofuel additives over sulfated activated carbon catalyst. Biores Technol 102:9229–9235. doi:10.1016/j.biortech.2011.07.035

Khayoon MS, Hameed BH (2013) Solventless acetalization of glycerol with acetone to fuel oxygenates over Ni–Zr supported on mesoporous activated carbon catalyst. Appl Catal A 464–465:191–199. doi:10.1016/j.apcata.2013.05.035

Knübel G, Bomhard A, Schaper UA, Stalberg T, Markert T (1997) US Patent 5,670,670

Liu X-Y et al (2010) Preparation of a carbon-based solid acid catalyst by sulfonating activated carbon in a chemical reduction process. Molecules 15:7188–7196. doi:10.3390/molecules15107188

Luo S, Falconer JL (1999) Acetone and acetaldehyde oligomerization on TiO2 surfaces. J Catal 185:393–407. doi:10.1006/jcat.1999.2511

Mahajani SM, Kolah AK, Sharma MM (1995) Extractive reactions with cationic exchange resins as catalysts (acetalization of aldehydes with alcohols). React Funct Polym 28:29–38. doi:10.1016/1381-5148(96)80152-0

Mandelli D, Carvalho WA, Shul’pina LS, Kirillov AM, Kirillova MV, Pombeiro AJ, Shul’pin GB (2013) Oxidation of glycerol with hydrogen peroxide catalyzed by metal complexes. In: Advances in organometallic chemistry and catalysis: the silver/gold jubilee international conference on organometallic chemistry celebratory book, Wiley, pp 247–257

Melero JA, Iglesias J, Morales G (2009) Heterogeneous acid catalysts for biodiesel production: current status and future challenges. Green Chem 11:1285–1308. doi:10.1039/B902086A

Mitsui T (1997) 4—cosmetics and fragrances. In: Mitsui T (ed) New cosmetic science. Elsevier, Amsterdam, pp 99–120. doi: 10.1016/B978-044482654-1/50006-5

Moreno-Castilla C, Ferro-Garcia MA, Joly JP, Bautista-Toledo I, Carrasco-Marin F, Rivera-Atrilla J (1995) Activated carbon surface modifications by nitric-acid, hydrogen-peroxide, and ammonium peroxydisulfate treatments. Langmuir 11:4386–4392. doi:10.1021/la00011a035

Mota CJA, Silva CXA, Gonçalves VLC (2009) Gliceroquímica: novos produtos e processos a partir da glicerina de produção de biodiesel. Quim Nova 32:639–648

Nanda S, Azargohar R, Dalai AK, Kozinski JA (2015) An assessment on the sustainability of lignocellulosic biomass for biorefining. Renew Sustain Energy Rev 50:925–941. doi:10.1016/j.rser.2015.05.058

Neely BJ, Wagner J, Robinson RL Jr, Gasem KAM (2008) Mutual solubility measurements of hydrocarbon-water systems containing benzene, toluene, and 3-methylpentane. J Chem Eng Data 53:165–174. doi:10.1021/je700449z

Olivier JP, Conklin WB, Vonszombathely M (1994) Determination of pore-size distribution from density functional theory—a comparison of nitrogen and argon results. Characterization of porous solid III. Stud Surf Sci Catal 87:81–89. doi:10.1016/S0167-2991(08)63067-0

Ozbay N, Oktar N, Dogu G, Dogu T (2013) Activity comparison of different solid acid catalysts in Etherification of glycerol with tert-butyl alcohol in flow and batch reactors. Top Catal 56:1790–1803. doi:10.1007/s11244-013-0116-0

Pawar RR, Jadhav SV, Bajaj HC (2014) Microwave-assisted rapid valorization of glycerol towards acetals and ketals. Chem Eng J 235:61–66. doi:10.1016/j.cej.2013.09.018

Petit C, Peterson GW, Mahle J, Bandosz TJ (2010) The effect of oxidation on the surface chemistry of sulfur-containing carbons and their arsine adsorption capacity. Carbon 48:1779–1787. doi:10.1016/j.carbon.2010.01.024

Rodrigues R, Goncalves M, Mandelli D, Pescarmona PP, Carvalho WA (2014) Solvent-free conversion of glycerol to solketal catalysed by activated carbons functionalised with acid groups. Catal Sci Technol 4:2293–2301. doi:10.1039/C4CY00181H

Rowan SJ, Cantrill SJ, Cousins GRL, Sanders JKM, Stoddart JF (2002) Dynamic covalent chemistry. Angew Chem Int Ed 41:898–952. doi:10.1002/1521-3773(20020315)41:6<898:AID-ANIE898>3.0.CO;2-E

Sharma A, Shinde Y, Pareek V, Zhang D (2015) Process modelling of biomass conversion to biofuels with combined heat and power. Biores Technol 198:309–315. doi:10.1016/j.biortech.2015.09.014

Silva VMTM, Rodrigues AE (2006) Kinetic studies in a batch reactor using ion exchange resin catalysts for oxygenates production: role of mass transfer mechanisms. Chem Eng Sci 61:316–331. doi:10.1016/j.ces.2005.07.017

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Reporting physisorption data for gas solid systems with special reference to the determination of surface-area and porosity (recommendations 1984). Pure Appl Chem 57:603–619. doi:10.1351/pac198557040603

Tao L-Z, Yan B, Liang Y, Xu B-Q (2013) Sustainable production of acrolein: catalytic performance of hydrated tantalum oxides for gas-phase dehydration of glycerol. Green Chem 15:696–705. doi:10.1039/c2gc16483c

Teng H, Tu Y-T, Lai Y-C, Lin C-C (2001) Reduction of NO with NH3 over carbon catalysts: the effects of treating carbon with H2SO4 and HNO3. Carbon 39:575–582. doi:10.1016/S0008-6223(00)00171-8

Thota GK, Tarigopula C, Balamurugan R (2015) Tandem activation by gold: synthesis of dioxolanes by intermolecular reaction of epoxides and alkynes in acetone. Tetrahedron 71:2280–2289. doi:10.1016/j.tet.2015.02.040

Umbarkar SB et al (2009) Acetalization of glycerol using mesoporous MoO3/SiO2 solid acid catalyst. J Mol Catal A 310:150–158. doi:10.1016/j.molcata.2009.06.010

Verma S, Nasir Baig RB, Nadagouda MN, Varma RS (2016) Visible light mediated upgrading of biomass to biofuel. Green Chem. doi:10.1039/C5GC02951A

Viswanadham N, Saxena SK (2013) Etherification of glycerol for improved production of oxygenates. Fuel 103:980–986. doi:10.1016/j.fuel.2012.06.057

Wang K, Hawley MC, DeAthos SJ (2003) Conversion of glycerol to 1,3-propanediol via selective dehydroxylation. Ind Eng Chem Res 42:2913–2923. doi:10.1021/ie020754h

Yavuz R, Akyildiz H, Karatepe N, Cetinkaya E (2010) Influence of preparation conditions on porous structures of olive stone activated by H3PO4. Fuel Process Technol 91:80–87. doi:10.1016/j.fuproc.2009.08.018

Zhang Y, Bi P, Wang J, Jiang P, Wu X, Xue H, Liu J, Zhou X, Li Q (2015) Production of jet and diesel biofuels from renewable lignocellulosic biomass. Appl Energy 150:128–137. doi:10.1016/j.apenergy.2015.04.023

Zhu S, Gao X, Dong F, Zhu Y, Zheng H, Li Y (2013) Design of a highly active silver-exchanged phosphotungstic acid catalyst for glycerol esterification with acetic acid. J Catal 306:155–163. doi:10.1016/j.jcat.2013.06.026

Acknowledgments

This work was supported by FAPESP (Project No. 2013/211260-6 and 2011/22264-4) and CNPq (Project No. 441936/2014-8).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material. Characterization (textural analysis and TGA), 1H, and 13C NMR spectra of the products, glycerol acetalization reaction with PA using AC as catalyst, effect of reaction temperature, catalyst stability, and recycling are included.

10098_2016_1136_MOESM1_ESM.tif

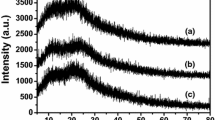

Supplementary material 1 (TIFF 4080 kb) Nitrogen adsorption/desorption isotherms and pore diameter distribution of parent and treated AC samples

10098_2016_1136_MOESM6_ESM.tif

Supplementary material 6 (TIFF 7978 kb) Glycerol acetalization reaction with PA using AC as catalyst (PA:glycerol molar ratio of 1:2, 383 K, 7.5 wt% catalyst)

10098_2016_1136_MOESM7_ESM.tif

Supplementary material 7 (TIFF 7978 kb) Effect of reaction temperature in the glycerol acetalization reaction with PA using AC-NS as catalyst (PA:glycerol molar ratio of 1:2, 7.5 wt% catalyst)

10098_2016_1136_MOESM8_ESM.tif

Supplementary material 8 (TIFF 8078 kb) Glycerol acetalization reaction with PA using AC-NS as catalyst as function of time and after catalyst separation from the reaction medium (PA:glycerol molar ratio of 1:2, 383 K, 7.5 wt% catalyst)

10098_2016_1136_MOESM9_ESM.tif

Supplementary material 9 (TIFF 8078 kb) Glycerol acetalization reaction with PA using AC-NS as catalyst in different use cycles (PA:glycerol molar ratio of 1:2, 383 K, 7.5 wt% catalyst)

10098_2016_1136_MOESM10_ESM.tif

Supplementary material 10 (TIFF 34811 kb) GC profile of Cycles 1, 2 and 3 of glycerol acetalization reaction with PA using AC-NS as catalyst (PA:glycerol molar ratio of 1:2, 383 K, 7.5 wt% catalyst)

Rights and permissions

About this article

Cite this article

Silva, C.A.C., Figueiredo, F.C.A., Rodrigues, R. et al. Enhancing the biodiesel manufacturing process by use of glycerin to produce hyacinth fragrance. Clean Techn Environ Policy 18, 1551–1563 (2016). https://doi.org/10.1007/s10098-016-1136-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1136-9