Abstract

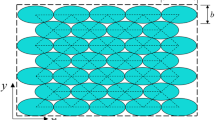

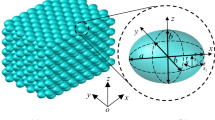

Using a microstructural mechanics approach, the close-packed elliptical particle assembly is first represented by a lattice model that is described by a beam system, and the Mohr–Coulomb (MC) shear failure criterion is used to describe the contact (beam) breakage. Through structural mechanics analysis of the unit cell, macroscopic strength criteria and associated parameters at two anisotropic principal directions are expressed in closed form with respect to the particle shape and microscopic strength parameters while considering the successive breakage of contacts. The macroscopic failure characteristics of elliptical particle assemblies are described by the MC failure criterion, and the macro–micro relations of strength parameters can be directly determined by the proposed expressions. The proposed analytical expressions are confirmed to be accurate due to the good consistency between theoretical and discrete element method (DEM) results based on the regular arrangement. The introduction of the fabric anisotropy parameter extends the applicability of the theoretical results to irregular arrangement cases, and the deviation with more realistic particle assemblies is investigated. The proposed expressions of the macroscopic strength parameters can help us better understand the influence of inherent anisotropy and microscopic properties and provide an alternative approach to determine the microscopic parameters in DEM simulations.

Similar content being viewed by others

Abbreviations

- \(a\), \(b\) :

-

Major and minor axes of the ellipse, respectively

- A, B :

-

Strength coefficients

- c p :

-

Contact cohesion

- c i (i = x, y):

-

Cohesion in the i anisotropic principal direction

- \(C_{u}^{i}\) (i = x, y):

-

Uniaxial compressive strength in the i anisotropic principal direction

- e :

-

Void ratio

- \(f_{ij}\) (i = n, s, m):

-

Contact force/moment in the i direction of Type-j beam

- F x, F y :

-

External forces acting on the unit cells of lattice

- \(k_{ij}\) (i = n, s, m):

-

Contact stiffness in the i direction of Type-j beams

- l j (j = 1, 2, 3):

-

Length of Type-j beams

- m :

-

Major–minor axis ratio of elliptical particles

- N t :

-

Coordinate number

- R t :

-

Contact tensile strength

- \(T_{u}^{i}\) (i = x, y):

-

Uniaxial tensile strength in the i anisotropic principal direction

- x i (i = n, s, m):

-

Relative displacement/rotation in the i direction

- α :

-

The angle between the normal and y directions at contact corresponding to beams 2 and 3

- γ :

-

Contact anisotropy ratio

- λ :

-

Tangential–normal contact stiffness ratio

- μ p :

-

Friction coefficient of contact

- ξ :

-

Rolling–normal contact stiffness ratio

- φ i (i = x, y):

-

Internal friction angle corresponding to the i anisotropic principal direction

- ∆:

-

Fabric anisotropy parameter

References

Tagliaferri, F., Waller, J., Andò, E., Hall, S.A., Viggiani, G., Bésuelle, P., DeJong, J.T.: Observing strain localisation processes in bio-cemented sand using x-ray imaging. Granul. Matter 13(3), 247–250 (2011)

Sahoo, S.K., Madhusudhan, B.N., Marín-Moreno, H., North, L.J., Ahmed, S., Falcon-Suarez, I.H., Minshull, T.A., Best, A.I.B.: Laboratory insights into the effect of sediment-hosted methane hydrate morphology on elastic wave velocity from time-lapse 4D synchrotron X-ray computed tomography. Geochem. Geophy. Geosy. 19, 4502–4521 (2018). https://doi.org/10.1029/2018gc007710

Jiang, M.J., Zhang, F.G., Hu, H.J., Cui, Y.J., Peng, J.B.: Structural characterization of natural loess and remolded loess under triaxial tests. Eng. Geol. 181, 249–260 (2014)

Dadda, A., Geindreau, C., Emeriault, F., Roscoat, S.R.D., Garandet, A.: Characterization of contact properties in biocemented sand using 3D X-ray micro-tomography. Acta Geotech. 14(3), 597–613 (2019)

Cundall, P.A., Strack, O.D.L.: Modeling of microscopic mechanisms in granular material. Stud. Appl. Mech. 7, 137–149 (1983)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Géotechnique 29(1), 47–65 (1979)

Potyondy, D.O., Cundall, P.A.: A bonded-particle model for rock. Int. J. Rock Mech. Min. 41(8), 1329–1364 (2004)

Jiang, M.J., Li, T., Hu, H.J., Thornton, C.: DEM analyses of one-dimensional compression and collapse behaviour of unsaturated structural loess. Comput. Geotech. 60, 47–60 (2014)

Jiang, M.J., He, J., Wang, J.F., Chareyre, B., Zhu, F.Y.: DEM analysis of geomechanical properties of cemented methane hydrate–bearing soils at different temperatures and pressures. Int. J. Geomech. 16(3), 04015087.1-04015087.25 (2016)

Hazzard, J.F., Young, R.P.: Simulating acoustic emissions in bonded particle models of rock. Int. J. Rock Mech. Min. 37(5), 867–872 (2000)

Boutt, D.F., McPherson, B.J.O.L.: Simulation of sedimentary rock deformation: lab-scale model calibration and parameterization. Geophys. Res. Lett. 29(4), 1054 (2002)

Chang, C.S., Wang, T.K., Sluys, L.J., Mier, J.G.M.V.: Fracture modeling using a micro-structural mechanics approach––I. Theory and formulation. Eng. Fract. Mech. 69(17), 1941–1958 (2002)

Chang, C.S., Chao, S.J., Chang, Y.: Estimates of elastic modulus for granular material with anisotropic random packing structure. Int. J. Solids Struct. 32(14), 1989–2008 (1995)

Griffiths, D.V., Mustoe, G.G.W.: Modelling of elastic continua using a grillage of structural elements based on discrete element concepts. Int. J. Numer. Meth. Eng. 50(7), 1759–1775 (2001)

Tavarez, F.A., Plesha, M.E.: Discrete element method for modelling solid and particulate materials. Int. J. Numer. Meth. Eng. 70(4), 379–404 (2007)

Liu, C., Pollard, D.D., Shi, B.: Analytical solutions and numerical tests of elastic and failure behaviors of close-packed lattice for brittle rocks and crystals. J. Geophys. Res.: Sol. Ea. 118(1), 71–82 (2013)

Liu, C., Xu, Q., Shi, B., Deng, S., Zhu, H.H.: Mechanical properties and energy conversion of 3D close-packed lattice model for brittle rocks. Comput. Geosci. 103, 12–20 (2017)

Wang, Y.C., Mora, P.: Macroscopic elastic properties of regular lattices. J. Mech. Phys. Solids 56(12), 3459–3474 (2008)

See, E.G., Ehlers, W., Ramm, E., Diebels, S., D’Addetta, G.: From particle ensembles to Cosserat continua: homogenization of contact forces towards stresses and couple stresses. Int. J. Solids Struct. 40(24), 6681–6702 (2003)

Chang, C.S., Gao, J.: Kinematic and static hypotheses for constitutive modelling of granulates considering particle rotation. Acta Mech. 115(1–4), 213–229 (1996)

Chang, C.S., Ma, L.: Modelling of discrete granulates as micropolar continuum. J. Eng. Mech. 116(112), 2703–2721 (1990)

Chang, C.S.: Estimates of elastic moduli for granular material with anisotropic random packing structure. Int. J. Solids Struct. 32(14), 1989–2008 (1995)

Zhou, Z.H., Wang, H.N., Jiang, M.J.: Elastic constants obtained analytically from microscopic features for regularly arranged elliptical particle assembly. Granul. Matter 23(2), 29 (2021)

Zhou, Z.H., Wang, H.N., Jiang, M.J.: Macro- and micro- mechanical relationship of the anisotropic behaviour of a bonded ellipsoidal particle assembly in the elastic stage. Acta Geotech. 16(12), 3899–3921 (2021)

Guedes, J.M., Kikuchi, N.: Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput. Method Appl. Mech. Eng. 83(2), 143–198 (1990)

Ghosh, S., Moorthy, S.: Elastic-plastic analysis of arbitrary heterogeneous materials with the Voronoi cell finite element method. Comput. Method Appl. Mech. Eng. 121(1–4), 373–409 (1995)

Costanzo, F., Boyd, J.G., Allen, D.H.: Micromechanics and homogenization of inelastic composite materials with growing cracks. J. Mech. Phys. Solids 44(3), 333–370 (1996)

Dvorak, G.J., Zhang, J.: Transformation field analysis of damage evolution in composite materials. J. Mech. Phys. Solids 49(11), 2517–2541 (2001)

Thornton, C.: The conditions for failure of a face-centered cubic array of uniform rigid spheres. Géotechnique 29(4), 441–459 (1979)

Suiker, A., Chang, C.S.: Modeling failure and deformation of an assembly of spheres with frictional contacts. J. Eng. Mech. 130(3), 283–293 (2004)

Benvenuti, L., Kloss, C., Pirker, S.: Identification of DEM simulation parameters by artificial neural networks and bulk experiments. Powder Technol. 291, 456–465 (2016)

Zhou, H., Hu, Z., Chen, J., Lv, X., Xie, N.: Calibration of DEM models for irregular particles based on experimental design method and bulk experiments. Powder Technol. 332, 210–223 (2018)

Qu, T.M., Feng, Y.T., Zhao, T., Wang, M.: Calibration of linear contact stiffnesses in discrete element models using a hybrid analytical-computational framework. Powder Technol. 356, 795–807 (2019)

Qu, T.M., Feng, Y.T., Wang, M., Jiang, S.Q.: Calibration of parallel bond parameters in bonded particle models via physics-informed adaptive moment optimisation. Powder Technol. 366, 527–536 (2020)

Qu, T.M., Feng, Y.T., Zhao, T., Wang, M.: A hybrid calibration approach to Hertz-type contact parameters for discrete element models. Int. J. Numer. Anal. Met. 44(9), 1281–1300 (2020)

Arthur, J.R.F., Menzies, B.K.: Inherent anisotropy in a sand. Géotechnique 22(1), 128–130 (1972)

Oda, M., Koishikawa, I., Higuchi, T.: Experimental study of anisotropic shear strength of sand by plane strain test. Soils Found. 18(1), 25–38 (1978)

Guo, P.J.: Modified direct shear test for anisotropic strength of sand. J. Geotech. Geoenviron. 134(9), 1311–1318 (2008)

Song, F., Zhang, J.M., Cao, G.R.: Experimental investigation of asymptotic state for anisotropic sand. Acta Geotech. 10(5), 571–585 (2015)

Tong, Z.X., Fu, P.C., Zhou, S.P., Dafalias, Y.F.: Experimental investigation of shear strength of sands with inherent fabric anisotropy. Acta Geotech. 9, 257–275 (2014)

Tatsuoka, F., Nakamura, S., Huang, C.-C., Tani, K.: Strength anisotropy and shear band direction in plane strain tests of sand. Soils Found. 30(1), 35–54 (1999)

Tatsuoka, F., Sakamoto, M., Kawamura, T., Fukushima, S.: Shear and deformation characteristics of sand in plane strain compression at extremely low pressure. Soils Found. 26(1), 65–84 (1986)

Lam, W.K., Tatsuoka, F.: Effects of initial anisotropic fabric and σ2 on strength and deformation characteristics of sand. Soils Found. 28(1), 89–106 (1988)

Mahmood, A., Mitchell, J.K.: Fabric–property relationships in fine granular materials. Clay. Clay Miner. 22, 397–408 (1974)

Azami, A., Pietruszczak, S., Guo, P.: Bearing capacity of shallow foundations in transversely isotropic granular media. Int. J. Numer. Anal. Met. 34(8), 771–793 (2010)

Farhadi, B., Lashkari, A.: Influence of soil inherent anisotropy on behavior of crushed sand-steel interfaces. Soils Found. 57(1), 111–125 (2017)

Ochiai, H., Lade, P.V.: Three-dimensional behavior of sand with anisotropic fabric. J. Geotech. Eng.: ASCE 109(10), 1313–1328 (1983)

Lade, P.V., Nam, J., Hong, W.P.: Shear banding sand cross-anisotropic behavior observed in laboratory sand tests with stress rotation. Can. Geotech. J. 45(1), 74–84 (2008)

Fu, P., Dafalias, Y.F.: Study of anisotropic shear strength of granular materials using DEM simulation. Int. J. Numer. Anal. Met. 35(10), 1098–1126 (2010)

Rothenburg, L., Bathurst, R.J.: Numerical simulation of idealized granular assemblies with plane elliptical particles. Comput. Geotech. 11(4), 315–329 (1991)

Hosseininia, E.S.: Investigating the micromechanical evolutions within inherently anisotropic granular materials using discrete element method. Granul. Matter 14(4), 483–503 (2012)

Jiang, M.J., Zhang, A., Fu, C.: 3-D DEM simulations of drained triaxial tests on inherently anisotropic granulates. Eur. J. Environ. Civ. En. 22(s1), 37–56 (2018)

Zhao, T., Dai, F., Xu, N.W., Liu, Y., Xu, Y.: A composite particle model for non-spherical particles in DEM simulations. Granul. Matter 17(6), 763–774 (2015)

Oda, M.: Initial fabrics and their relations to mechanical properties of granular material. Soils Found. 12(1), 17–36 (1972)

Yang, Z.X., Li, X.S., Yang, J.: Quantifying and modelling fabric anisotropy of granular soils. Géotechnique 58(4), 237–248 (2008)

Walton, K.: The effective elastic modulus of a random packing of spheres. J. Mech. Phys. Solids 35(2), 213–226 (1987)

Herrmann, H.J., Hansen, A., Roux, S.: Fracture of disordered, elastic lattices in two dimensions. Phys. Rev.: B 39(1), 637–648 (1989)

Pollard, D.D., Fletcher, R.C.: Fundamentals of Structural Geology. Cambridge University Press, United Kingdom (2005)

Goodman RE: Introduction to Rock Mechanics. 2nd, Wiley (1989)

Ng, T.T.: Numerical simulations of granular soil using elliptical particles. Comput. Geotech. 16(2), 153–169 (1994)

Zheng, Q.J., Zhou, Z.Y., Yu, A.B.: Contact forces between viscoelastic ellipsoidal particles. Powder Technol. 248, 25–33 (2013)

ITASCA: Particle Flow Code in Three Dimensions. User’s Guide. Itasca Consulting Group Inc., Minnesota (2008)

Cambou, B.: Micromechanical approach in granular materials. In: Cambou, B. (ed.) Behaviour of Granular Materials International Centre for Mechanical Sciences, vol. 385. Springer, Vienna (1998)

Jiang, M.J., Konrad, J.M., Leroueil, S.: An efficient technique for generating homogeneous specimens for DEM studies. Comput. Geotech. 30(7), 579–597 (2003)

Yang, B., Jiao, Y., Lei, S.: A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng. Comput. 23(6), 607–631 (2006)

Huang, H.Y.: Discrete element modeling of tool-rock interaction. Ph.D. Thesis, University of Minnesota, Minneapolis, America (1999)

Leet, K., Uang, C.M., Gilbert, A.M.: Fundamentals of Structural Analysis, 5th edn. McGraw-Hill Education, Chichester (2017)

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant Nos. 11872281, 12272274, and 51890911) and the State Key Laboratory of Disaster Reduction in Civil Engineering (Grant No. SLDRCE19-A-06).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

Figure

15 shows the force analysis of the unit cell in Fig. 1c, where F1, F2, and F3 are the redundant axial force, shear force, and bending moment of the rigid beams (Type-3 beam), respectively. According to the symmetric characteristic of the unit, Fi (i = 1, 2, 3) in beams 4 and 7 are equal to each other.

If \(\delta_{ij}\) and \(\Delta_{{i{\text{P}}}}\) are the displacement in the Fi (= 1, 2, 3) direction induced by the unit redundant force \(\overline{F}_{j} (j = {1, 2, 3})\) and external forces Fx and Fy, respectively, they can be calculated by the principle of virtual work as follows:

where \(k_{ih}\)(i = n, s, m) and lh are the contact stiffness along the i direction and length of beam h, respectively; k is a parameter related to the shape of the cross-section; and n = 7 is the number of rigid beams. Additionally, \(\overline{F}_{{{\text{N}}ih}}\),\(\overline{F}_{{{\text{S}}ih}}\) and \(\overline{M}_{ih}\) (\(F_{{{\text{NP}}h}}\), \(F_{{{\text{SP}}h}}\) and \(M_{{{\text{P}}h}}\)) are the axial force, shear force, and bending moment of beam h induced by the unit redundant force \(\overline{F}_{i}\) (external forces Fx and Fy), respectively, which are the function of normal direction in the local coordinate system of beam h. dl is the differential of length of beam h. Noted that, to keep consistent with the theoretical derivation, the material constants of original principle of virtual work [67] are replaced by contact stiffesses \(k_{i}\) in this study through the relations between material constants and contact stiffesses according to the beam model. Therefore, \(\delta_{ij}\) and \(\Delta_{{i{\text{P}}}}\) can be expressed as:

Substituting Eq. (48) into the typical equations of the force method in structure mechanics \(\delta_{ij} F_{i} + \Delta_{ip} = 0\) [67], the redundant force Fi of rigid beams 4 and 7 can be expressed as:

where:

Substituting Eqs. (1–3) into Eq. (50) and considering the relation of m, we obtain the dimensionless strength coefficients in Eq. (12), which are expressed by microscopic parameters, including the major-minor axis ratio m and stiffness ratios λ, ξ, γ. After the redundant force of rigid beams 4 and 7 is determined, the internal forces of all remaining beams can be obtained by force analysis of the statically determinate structure, and the axial and shear forces of beams 1 and 2, 3, 5 and 6 can be expressed by strength coefficients A and B as follows:

and:

Letting fx or fy = 0, we can obtain the expressions of axial and shear forces of beams 2, 3, 5 and 6 and 1 for the uniaxial tension loading situations in the y or x directions in Eqs. (28) and (31), respectively.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, Z., Wang, H. & Jiang, M. Strength criteria at anisotropic principal directions expressed in closed form by interparticle parameters for elliptical particle assembly. Granular Matter 25, 1 (2023). https://doi.org/10.1007/s10035-022-01285-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-022-01285-9