Abstract

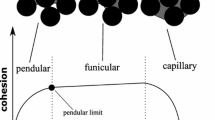

Liefferink et al. (GM 22: 57, 2020) reported the effect of liquid volume fraction on the penetration hardness/shear modulus and the friction coefficient of several types of wet sand. However, no analytical equation can simultaneously explain these two observations. In this paper, we formulate the effective elastic modulus of wet granular material as a function of the liquid volume fraction using the effective medium approximation. We also propose the equation of the friction coefficient between the surface of an object and the surface of the wet granular materials. The equations for the modulus of elasticity and coefficient of friction as a function of the liquid volume fraction can well explain the observed data by using a few adjusted parameters.

Graphic abstract

Similar content being viewed by others

References

Liefferink, R.W., Aliasgari, M., Maleki-Jirsaraei, N., Rouhani, S., Bonn, D.: Sliding on wet sand. Granul. Matter. 22, 57 (2020). https://doi.org/10.1007/s10035-020-01022-0

Albert, R., Pfeifer, M.A., Barabási, A.L., Schiffer, P.: Slow drag in a granular medium. Phys. Rev. Lett. 82, 205–208 (1999). https://doi.org/10.1103/PhysRevLett.82.205

Pakpour, M., Habibi, M., Møller, P., Bonn, D.: How to construct the perfect sandcastle. Sci. Rep. 2, 549 (2012). https://doi.org/10.1038/srep00549

Fall, A., Weber, B., Pakpour, M., Lenoir, N., Shahidzadeh, N., Fiscina, J., Wagner, C., Bonn, D.: Sliding friction on wet and dry sand. Phys. Rev. Lett. 112, 175502 (2014). https://doi.org/10.1103/PhysRevLett.112.175502

Yuliza, E., Amalia, N., Rahmayanti, H.D., Munir, R., Munir, M.M., Khairurrijal, K., Abdullah, M.: Stability of granular tunnel. Granul. Matter. 20, 75 (2018). https://doi.org/10.1007/s10035-018-0847-5

Fournier, Z., Geromichalos, D., Herminghaus, S., Kohonen, M.M., Mugele, F., Scheel, M., Schulz, M., Schulz, B., Schier, C., Seemann, R., Skudelny, A.: Mechanical properties of wet granular materials. J. Phys. Condens. Matter. 17, S477–S502 (2005). https://doi.org/10.1088/0953-8984/17/9/013

El Korchi, F.Z., Jamin, F., El Youssoufi, M.S.: Collapse of granular media subjected to wetting. EPJ Web Conf. 140, 10010 (2017). https://doi.org/10.1051/epjconf/201714010010

Halsey, T.C., Levine, A.J.: How sandcastles fall. Phys. Rev. Lett. 80, 3141–3144 (1998). https://doi.org/10.1103/PhysRevLett.80.3141

Macaulay, M., Rognon, P.: Viscosity of cohesive granular flows. Soft Matter 17, 165–173 (2021). https://doi.org/10.1039/d0sm01456g

Møller, P.C.F., Bonn, D.: The shear modulus of wet granular matter. Europhys. Lett. 80, 38002 (2007). https://doi.org/10.1209/0295-5075/80/38002

Pacheco-Vázquez, F., Moreau, F., Vandewalle, N., Dorbolo, S.: Sculpting sandcastles grain by grain: self-assembled sand towers. Phys. Rev. E. 86, 051303 (2012). https://doi.org/10.1103/PhysRevE.86.051303

Budiansky, B.: On the elastic moduli of some heterogeneous materials. J. Mech. Phys. Solids 13, 223–227 (1965). https://doi.org/10.1016/0022-5096(65)90011-6

Snarskii, A.A., Shamonin, M., Yuskevich, P.: Effective medium theory for the elastic properties of composite materials with various percolation thresholds. Materials 13, 1243 (2020). https://doi.org/10.3390/ma13051243

Timoshenko, S., Gere, M.J.: Theory of Elastic Stability. McGraw-Hill, New York (1982)

Sun, Q., Jin, F., Wang, G., Song, S., Zhang, G.: On granular elasticity. Sci. Rep. 5, 9652 (2015). https://doi.org/10.1038/srep09652

Chang, C.S., Chao, S.J., Chang, Y.: Estimates of elastic moduli for granular material with anisotropic random packing structure. Int. J. Solids Struct. 32(14), 1989–2008 (1995). https://doi.org/10.1016/0020-7683(94)00225-L

Hemmerle, A., Schröter, M., Goehring, L.: A cohesive granular material with tunable elasticity. Sci. Rep. 6, 35650 (2016). https://doi.org/10.1038/srep35650

Bruggeman, D.A.G.: Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen: I—dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Phys. 416, 636–664 (1935). https://doi.org/10.1002/andp.19354160705

Landauer, R.: The electrical resistance of binary metallic mixtures. J. Appl. Phys. 23(7), 779–784 (1952). https://doi.org/10.1063/1.1702301

Hill, R.: A self-consistent mechanics of composite materials. J. Mech. Phys. Solids. 13(4), 213–222 (1965). https://doi.org/10.1016/0022-5096(65)90010-4

Zamponi, F.: Packings close and loose. Nature 453, 606–607 (2008). https://doi.org/10.1038/453606a

Bergman, D.J., Kantor, Y.: Critical properties of an elastic fractal. Phys. Rev. Lett. 53, 511 (1984). https://doi.org/10.1103/PhysRevLett.53.511

Miwa, M., Horiba, N.: Effects of fibre length on tensile strength of carbon/glass fibre hybrid composites. J. Mater. Sci. 29, 973–977 (1994). https://doi.org/10.1007/BF00351419

Naveen, P.N.E., Yasaswi, M.: Experimental analysis of coir-fiber reinforced polymer composite materials. Int. J. Mech. Eng. Rob. Res. 2, 10–18 (2013)

Taketa, I., Matsutani, H.: Effect of fiber length on the tensile strength of unidirectionally arrayed chopped strands. Adv. Compos. Mater. 29, 43–54 (2020). https://doi.org/10.1080/09243046.2019.1650321

Fu, S.-Y., Hu, X., Yue, C.-Y.: Effects of fiber length and orientation distributions on the mechanical properties of short-fiber-reinforced polymers. Mater. Sci. Res. Int. 5, 74–83 (1999). https://doi.org/10.2472/jsms.48.6Appendix_74

Kumar, R., Hashmi, A.A.R., Nimanpure, S., Naik, A.: Enhanced dynamic mechanical properties of kenaf epoxy composites. Adv. Mater. Proc. 2, 749–757 (2017). https://doi.org/10.5185/amp.2017/981

Mikrajuddin, Shi, F.G., Okuyama, K.: Electrical conduction in insulator particle – solid-state ionic and conducting particle-insulator matrix composites : a unified theory. J. Electrochem. Soc. 147, 3157–3165 (2000). https://doi.org/10.1149/1.1393876

Abdullah, M., Lenggoro, I.W., Okuyama, K., Shi, F.G.: In situ synthesis of polymer nanocomposite electrolytes emitting a high luminescence with a tunable wavelength. J. Phys. Chem. B. 107, 1957–1961 (2003). https://doi.org/10.1021/jp022223c

Mikrajuddin, A., Shi, F.G., Chungpaiboonpatana, S., Okuyama, K., Davidson, C., Adams, J.M.: Onset of electrical conduction in isotropic conductive adhesives : a general theory. Mater. Sci. Semicond. Process. 2, 309–319 (1999). https://doi.org/10.1016/S1369-8001(99)00035-9

Sharma, H., Dukes, M., Olsen, D.: Field measurements of dynamic moduli and poisson’s ratios of refuse and underlying soils at a landfill site," in Geotechnics of Waste Fills—Theory and Practice, ed. A. Landva and G. Knowles. In: ASTM International. pp. 57–709 (1990)

Weisstein, E.: Cubic formula. From Wolfram Math World, https://mathworld.wolfram.com/CubicFormula.html. Retrieved on May 10, 2021

Coppersmith, S.N., Majumdar, S., Narayan, O., Witten, T.A.: Model for forece fluctuation in bead packs. Phys. Rev. E. 53, 4673–4685 (1996). https://doi.org/10.1103/PhysRevE.53.4673

Liu, C.H., Nagel, S.R., Schecter, D.A., Coppersmith, S.N., Majumdar, S., Narayan, O., Witten, T.A.: Force fluctuations in bead packs. Science 269, 513–515 (1995). https://doi.org/10.1126/science.269.5223.513

McKee, C.T., Last, J.A., Russell, P., Murphy, C.J.: Indentation versus tensile measurements of young’s modulus for soft biological tissues. Tissue Eng. Part B. 17, 155–164 (2011). https://doi.org/10.1089/ten.teb.2010.0520

Brzinski, T.A., Mayor, P., Durian, D.J.: Depth-dependent resistance of granular media to vertical penetration. Phys. Rev. Lett. 111, 168002 (2013). https://doi.org/10.1103/PhysRevLett.111.168002

Katsuragi, H., Durian, D.J.: Unified force law for granular impact cratering. Nat. Phys. 3, 420–423 (2007). https://doi.org/10.1038/nphys583

Oda, M.: Co-ordination number and its relation to shear strength of granular material. Soils Found. 17, 29–42 (1977). https://doi.org/10.3208/sandf1972.17.2_29

O’Hern, C.S., Silbert, L.E., Liu, A.J., Nagel, S.R.: Jamming at zero temperature and zero applied stress: the epitome of disorder. Phys. Rev. E. 68, 011306 (2003). https://doi.org/10.1103/PhysRevE.68.011306

Matsushima, T., Uesugi, K., Nakano, T., Tsuchiyama, A.: Microstructural quantification of granular assembly studied by Micro X-ray CT at SPring-8. J. Appl. Mech. 11, 507–515 (2008). https://doi.org/10.2208/journalam.11.507

Ueda, T., Matsushima, T., Yamada, Y.: Effect of particle size ratio and volume fraction on shear strength of binary granular mixture. Granul. Matter. 13, 731–742 (2011). https://doi.org/10.1007/s10035-011-0292-1

Liefferink, R.W., Weber, B., Bonn, D.: Ploughing friction on wet and dry sand. Phys. Rev. E. 98, 052903 (2018). https://doi.org/10.1103/PhysRevE.98.052903

Shahidzadeh-Bonn, N., Vie, P., Chateau, X., Roux, J.-N., Bonn, D.: Delayed fracture in porous media. Phys. Rev. Lett. 95, 175501 (2005). https://doi.org/10.1103/PhysRevLett.95.175501

Shahixpoor, M.: Statistical mechanical considerations on the random packing of granular materials. Powder Technol. 25, 163–176 (1980). https://doi.org/10.1016/0032-5910(80)87027-6

Bernabé, Y., Li, M., Tang, Y.-B., Evans, B.: Pore Space connectivity and the transport properties of rocks. Oil Gas Sci. Technol. Rev. 71, 50 (2016). https://doi.org/10.2516/ogst/2015037

Poplavko, Y.M.: Mechanical properties of solids. Electron. Mater. Princip. Appl. Sci. (2019). https://doi.org/10.1016/B978-0-12-815780-0.00002-5

Spinner, S., Knudsen, F.P., Stone, L.: Elastic constant-porosity relations for polycrystalline thoria. J. Res. Natl. Bur. Stand. 67C, 39 (1963). https://doi.org/10.6028/jres.067C.005

Martin, L.P., Dadon, D., Rosen, M.: Evaluation of ultrasonically determined elasticity-porosity relations in zinc oxide. J. Am. Ceram. Soc. 79(5), 1281–1289 (1996). https://doi.org/10.1111/j.1151-2916.1996.tb08585.x

Shamonin, M., Yuskevich, P.: Effective medium theory for the elastic properties of composite materials with various percolation thresholds. Materials 13, 1243 (2020). https://doi.org/10.3390/ma13051243

Berryman, J.G.: Effective medium approximation for elastic constants of porous solids with microscopic heterogeneity. J. Appl. Phys. 59, 1136 (1986). https://doi.org/10.1063/1.336550

Hornby, B.E., Schwartzt, L.M., Hudson, J.A.: Anisotropic effective-medium modeling of the elastic properties of shales. Geophys. 59, 1570–1583 (1994). https://doi.org/10.1190/1.1443546

Berryman, J.G.: Hybrid effective medium approximations for random elastic composites. Mech. Mater. 70, 115–135 (2014). https://doi.org/10.1016/j.mechmat.2013.11.003

Skomski, R., Li, J., Zhou, J., Sellmyer, D.J.: Multiscale phenomena in Bruggeman composites. Mater. Res. Soc. Symp. Proc. (2005). https://doi.org/10.1557/PROC-851-NN1.7

Huang, Y., Hu, K.X.: Elastic moduli of a microcracked composite with spherical inclusions of cubic anisotropy. Compos. Sci. Technol. 50, 149–156 (1994). https://doi.org/10.1016/0266-3538(94)90136-8

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

We will show approximately that Eq. (10) can be derived from Eq. (1) with the assumption that the effective Poisson’s ratio can be considered not to change significantly. With this assumption, Eqs. (1) and (2), which are coupled equations become two separate equations. Equation (1) can be written in the following form

With several mathematical steps, Eq. (32) can be rewritten as

Let us look at the right side of Eq. (33). If the volume of the liquid fraction is close to zero (the granular system is almost dry), \(p_{dd} \approx 1\), \(p_{dw} \approx p_{ww} \approx 0\), and \(G_{e} = G_{dd}\). As a result, the right side of Eq. (33) becomes \(\approx 0\). If the volume fraction of the liquid is very high so that \(p_{ww} \approx 1\), \(p_{dd} \approx p_{dw} \approx 0\), and \(G_{e} = G_{ww}\) so that the right-hand side of Eq. (33) is also close to zero. For the case of wet granular materials, \(G_{dw} > G_{dd}\) and \(G_{dw} > G_{ww}\). When the shear modulus approaches the peak, \(p_{dw}\) is not too small and \(G_{e}\) is close \(G_{dw}\) but smaller. If this condition is reached and we approximate \(G_{e} /G_{dd} \to \infty\) and \(G_{e} /G_{dd} \to \infty\) (this is actually a rough approximation), the right-hand side of Eq. (33) approaches

Since \(p_{dw} = O\left( 1 \right)\), \(1 + \left( {1/\beta_{e} - 1} \right)G_{e} /G_{dw} < 1 + \left( {1/\beta_{e} - 1} \right) = 1/\beta_{e}\), we obtain \(p_{dw} /\left[ {1 + \left( {1/\beta_{e} - 1} \right)G_{e} /G_{dw} } \right] \approx \beta_{e} O\left( 1 \right)\) and the right-hand side of Eq. (33) is approximately \(\approx - \beta_{e} + \beta_{e} O\left( 1 \right) \approx 0\). From this analysis we can conclude that Eq. (33) can be approximated by the following equation

Each term of Eq. (34) can be written as

The Poisson ratios of most sand granules are approximately 0.3–0.4 [31]. Assuming that the effective Poisson’s ratio does not differ much from this value, we can approximate \(\left( {1 + v_{e} } \right)/\left( {1 + v_{i} } \right) \approx 1\) and we get the equation

where \(i = dd\), \(dw\), and \(ww\). This approximate equation is very similar to the EMA equation which has been used to explain the formation of electrical conductivity in composites [28,29,30],

by analogizing \(1/\beta_{e}\) as \(z/2\), where \(z\) is the coordination number. This analogy does not produce very different estimates.

As mentioned above, the value of \(\beta_{e}\) for sand granules is in the range of 0.44–0.48. The Poisson’s ratio for most materials varies from zero (for very brittle materials) to 0.7 (a completely elastic material) [46] so, assuming \(v_{e}\) is in that range, then the range of values for \(\beta_{e}\) is between 0.22 and 0.53. Taking \(z \approx 4.5 - 7.5\) [40, 41], we obtain \(2/z\) between 0.27 and 0.44, which is not much different from \(\beta_{e}\). According to Hill [20], \(\beta_{e}\) is in the range 0.4–0.6; is very near 0.45 for most metals \(\beta_{e}\). An interesting result is the report of Spinner et al. [47] on the effect of porosity on the Poisson’s ratio of porous thorium oxide (ThO2), where the Poisson’s ratio decreases with increasing porosity. Hill [20] has obtained the dependent equation of Poisson’s ratio to volume fraction of one component of the composite composed of two components according to the equation \(v_{e} = \left( {p_{1} v_{1} + p_{2} v_{2} - v_{1} v_{2} } \right)/\left( {1 - p_{1} v_{2} - p_{2} v_{1} } \right)\). For porous materials, the second component is a vacuum so we can take \(v_{2} = 0\). If porosity is \(\phi\), \(p = 1 - \phi\) so \(v_{e} = \left( {1 - \phi } \right)v_{1} /\left( {1 - \phi v_{1} } \right)\). It is easy to prove that \(v_{e}\) decreases with increasing \(\phi\) in the range \(0 \le \phi \le 1\). Martin et al. [48] also proved that for porous ZnO, the Poisson’s ratio decreases with increasing porosity according to the empirical equation \(v = v_{0} \left( {1 - \phi } \right)^{\tau }\), where \(v_{0}\) is the porosity of the solid material and \(\tau = 1.12\). These results can be understood because the greater the porosity, the more brittle the material is so that the Poisson’s ratio is getting smaller. We can easily show that \(\beta_{e}\) gets bigger as Poisson ratio gets smaller. And intuitively, because the volume of the material is getting smaller when the porosity is greater, the greater the porosity, the lesser dense the material which causes the coordination number to be smaller. So, we conclude that the greater the porosity of the material, the smaller \(1/\beta_{e}\) according to the change in \(z/2\), which supports the analogy of \(1/\beta_{e}\) as \(z/2\) is reasonable.

Indeed, the value of \(z/2\) is not exactly equal to \(1/\beta_{e}\). For equations that have been derived by a number of approximations, these differences could be tolerated. By looking at the similarities above, we will use Eq. (10) to estimate the elastic modulus of the granular material. Thus, the equation for estimating the modulus of elasticity proposed here is different from that reported by many researchers [12, 13, 20, 49,50,51,52,53,54].

Rights and permissions

About this article

Cite this article

Abdullah, M., Rahmayanti, H.D., Amalia, N. et al. Effective elastic modulus of wet granular materials derived from modified effective medium approximation and proposal of an equation for the friction coefficient between the object and wet granular materials surfaces. Granular Matter 23, 78 (2021). https://doi.org/10.1007/s10035-021-01144-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01144-z