Abstract

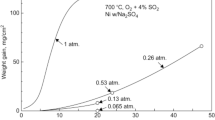

The electrochemical behavior of single-layer TiN, CrN, CrAlN, and TiAlN coatings on 304 stainless steel substrate, deposited using state-of-the-art and industrial size cathodic arc PVD machine, were evaluated in 1M HCl and 3.5 pct NaCl solutions. The corrosion behavior of the blank and coated substrates was analyzed by electrochemical impedance spectroscopy (EIS), linear polarization resistance, and potentiodynamic polarization. Bond-coat layers of pure-Ti, pure-Cr, alloyed-CrAl, and alloyed-TiAl for TiN, CrN, CrAlN, and TiAlN coatings were, respectively, first deposited for improved coating adhesion before the actual coating. The average coating thickness was about 1.80 µm. Results showed that the corrosion potentials (E corr) of the coated substrates were shifted to more noble values which indicated improvement of the coated substrate resistance to corrosion susceptibility. The corrosion current densities were lower for all coated substrates as compared to the blank substrate. Similarly, EIS parameters showed that these coatings possessed improved resistance to defects and pores in similar solution compared to the same nitride coatings developed by magnetron sputtering. The charge transfer resistance (R ct) can be ranked in the following order: TiAlN > CrN > TiN > CrAlN in both media except in NaCl solution where R ct of TiN is lowest. While the pore resistance (R po) followed the order: CrAlN > CrN > TiAlN > TiN in HCl solution and TiAlN > CrN > CrAlN > TiN in NaCl solution. It is found that TiAlN coating has the highest protective efficiencies of 79 and 99 pct in 1M HCl and 3.5 pct NaCl, respectively. SEM analysis of the corroded substrates in both media was also presented.

Similar content being viewed by others

References

Y. Li, L. Qu, and F. Wang: 2003, Corrosion Science, vol. 45, no. 7, pp. 1367–1381.

R. M. Souto, H. Alanyali: 2000, Corrosion Science, vol. 42, pp. 2201–2211.

V. K. William Grips, H. C. Barshilia, V. E. Selvi, and K. S. Rajam: 2006, Thin Solid Films, vol. 514, no. 1–2, pp. 204–211.

C. Liu, Q. Bi, and A. Matthews: 2001, Corrosion Science, vol. 43, pp. 1953–1961.

X. Ding, A. L. K. Tan, X. T. Zeng, C. Wang, T. Yue, and C. Q. Sun: 2008, Thin Solid Films, vol. 516, no. 16, pp. 5716–5720.

C. Petrogalli, L. Montesano, M. Gelfi, G. M. La Vecchia, and L. Solazzi: 2014, Surf. Coatings Technol., vol. 258, pp. 878–885.

F. Caiazzo, V. Sisti, S. Trasatti, and S. Trasatti: 2014, Coatings, vol. 4, no. 3, pp. 508–526,

F. C. Caiazzo, V. Sisti, and S. Trasatti: 2014, Metall. Ital, vol. 106, pp. 3–8.

G.-H. Song, X.-P. Yang, G.-L. Xiong, Z. Lou, and L.-J. Chen: 2013, Vacuum, vol. 89, pp. 136–141.

W. Chou, G. Yu, and J. Huang: 2001, Corros. Sci., vol. 43, pp. 2023–2035.

S. Korablov, M. A. M. Ibrahim, and M. Yoshimura: 2005, Corros. Sci., vol. 47, no. 7, pp. 1839–1854.

O. Cegil, B. Kılınc, S. Sen, and U. Sen: 2014, Acta Phys. Pol. A, vol. 125, no. 2, pp. 359–61.

S. J. Bull and A. M. Jones: 1996, Surf. Coatings Technol., vol. 78, no. 7, pp. 173–184.

J. Y. Rauch, C. Rousselot, and N. Martin: 2002, Surf. Coat. Technol., vol. 157, pp. 138–143.

K. Rajeev and B. Tiwari: 2012, Int. J. Metall. Mater. Sci. Eng., vol. 2, no. 3, pp. 11–21.

Sulzer Metco, The World of Metalworking, (2011).

C. Sujaya and H. D. Shashikala: 2012, Surf. Eng. Appl. Electrochem., vol. 48, no. 2, pp. 133–140.

N. A. Odewunmi, S. A. Umoren, and Z. M. Gasem: 2015, J. Ind. Eng. Chem., vol. 21, pp. 239–247.

A. Madhankumar, S. Nagarajan, N. Rajendran, and T. Nishimura: 2012, J. Solid State Electrochem., vol. 16, no. 6, pp. 2085–2093.

A. MadhanKumar, R. SureshBabu, I. B. Obot, and Z. M. Gasem: 2015, RSC Advances, vol. 5, no. 25, pp. 19264–72.

V. Chawla: 2013, J. Mater. Sci. Eng., vol. A3, no. 1, pp. 22–30.

B. Matthes, E. Broszeit, J. Aromaa, H. Ronkainen, S.-P. Hannula, A. Leyland, and A. Matthews: 1991, Surf. Coatings Technol., vol. 49, no. 1–3, pp. 489–495.

J. Creus, H. Mazille, and H. Idrissi: 2000, Surf. Coatings Technol., vol. 130, no. 2–3, pp. 224–232.

M. A. M. Ibrahim, S. F. Korablov, and M. Yoshimura: 2002, Corros. Sci., vol. 44, pp. 815–828.

X. Ding, A. L. K. Tan, X. T. Zeng, C. Wang, T. Yue, and C. Q. Sun: 2008, Thin Solid Films, vol. 516, no. 16, pp. 5716–5720.

V. Chawla, D. Puri, S. Prakash, A. Chawla, and B. Singh: 2009, J. Mater. Mater. Charact. & Engineering, vol. 8, no. 9, pp. 715–727.

V. Chawla, A. Chawla, B.S. Sidhu, S. Prakash, D. Puri: 2010, J. Miner. Mater. Charact. Eng., vol. 11, no. 9, pp. 1037–1057.

Acknowledgments

The authors acknowledge the support received from King Abdulaziz City for Science and Technology (KACST), Riyadh, Saudi Arabia, for funding this work under the National Science Technology Plan (NSTIP) Grant No. 09-ADV764-04. Also, the Ph.D. Scholarship provided by King Fahd University of Petroleum and Minerals (KFUPM) for A.Y.A. is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 20, 2016.

Rights and permissions

About this article

Cite this article

Adesina, A.Y., Gasem, Z.M. & Madhan Kumar, A. Corrosion Resistance Behavior of Single-Layer Cathodic Arc PVD Nitride-Base Coatings in 1M HCl and 3.5 pct NaCl Solutions. Metall Mater Trans B 48, 1321–1332 (2017). https://doi.org/10.1007/s11663-016-0891-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0891-7