Abstract

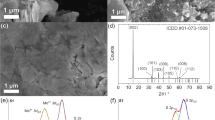

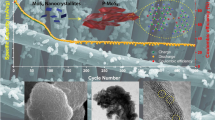

Choice of binder and the electrode-making process play a pivotal role in the electrochemical performance of MoS2, when used as lithium-ion battery anode. In this work, MoS2 nanorods are prepared by gas phase synthesis method using molybdenum trioxide (MoO3) nanobelts and sulfur as starting materials. It has been observed that by tuning the reaction conditions, morphology and yield of the final product can be controlled. Carboxymethyl cellulose (CMC) is used as binder to fabricate the MoS2 electrode, and its electrochemical performance is tested against Li/Li+. The performance of electrode can be further improved by incorporating heat treatment to the active material and conductive carbon mixture prior to electrode fabrication. The electrochemical data shows that the optimum temperature for heat treatment is 700 °C. In the current report, we would like to elucidate a detailed study based on electrode fabrication process and their impact on the electrochemical performance.

Similar content being viewed by others

References

Poizot P, Laruelle S, Grugeon S, Dupont L, Tarascon JM (2000) Nature 407:496–499

Sen UK, Srakar S, Veluri PS, Singh S, Mitra S (2013) Nanosci Nanotechnol Asia 3:21–35

Bruce PG, Scrosati B, Tarascon JM (2008) Angew Chem Int Ed 47:2930–2946

Taberna PL, Mitra S, Poizot P, Simon P, Tarascon JM (2006) Nat Mater 5:567–573

Reddy MV, Yu T, Sow CH, Shen ZX, Lim CT, Rao GVS, Chowdari BVR (2007) Adv Funct Mater 17:2792–2799

Chang K, Chen W (2011) ACS Nano 6:4720–4728

Cao X, Shi Y, Shi W, Rui X, Yan Q, Kong J, Zhang H (2013) Small 9:3433–3438

Wang Z, Chen T, Chen W, Chang K, Ma L, Huang G, Chen D, Lee JY (2013) J Mater Chem A 1:2202–2210

Bindumadhavan K, Srivastava SK, Mahanty S (2013) Chem Commun 49:1823–1825

Park SK, Yu SH, Woo S, Quan B, Lee DC, Kim MK, Sung YE, Piao Y (2013) Dalton Trans 42:2399–2405

Chang K, Chen W, Ma L, Li H, Li H, Huang F, Xu Z, Zhangd Q, Lee JY (2011) J Mater Chem 21:6251–6257

Zhou X, Wan LJ, Guo YG (2012) Nanoscale 4:5868–5871

Sen UK, Mitra S (2013) ACS Appl Mater Interfaces 5:1240–1247

Li J, Dahn HM, Krause LJ, Le DB, Dahn JR (2008) J Electrochem Soc 155:A812–A816

Liu G, Zheng H, Kim S, Deng Y, Minor AM, Song X, Battaglia VS (2008) J Electrochem Soc 155:A887–A892

Liu G, Zheng H, Simens AS, Minor AM, Song X, Battaglia VS (2007) J Electrochem Soc 154:A1129–A1134

Veluri PS, Mitra S (2013) RSC Adv 3:15132–15138

Wang Z, Madhavi S, Lou XW (2012) J Phys Chem C 116:12508–12513

Gillot F, Boyanov S, Dupont L, Doublet ML, Morcrette M, Monconduit L, Tarascon JM (2005) Chem Mater 17:6327–6337

Gu Y, Xu Y, Wang Y (2013) ACS Appl Mater Interfaces 5:801–806

Wang Y, Wu J, Tang Y, Lü X, Yang C, Qin M, Huang F, Li X, Zhang X (2012) ACS Appl Mater Interfaces 4:4246–4250

Liu H, Su D, Wang G, Qiao SZ (2012) J Mater Chem 22:17437–17440

Bhandavat R, David L, Singh G (2012) J Phys Chem Lett 3:1523–1530

Feldman Y, Wasserman E, Srolovitz DJ, Tenne R (1995) Science 267:222–225

Li XL, Li YD (2003) Chem Euo J 9:2726–2731

Hsu WK, Chang BH, Zhu YQ, Han WQ, Terrones H, Terrones M, Grobert N, Cheetham AK, Kroto HW, Walton DRM (2000) J Am Chem Soc 122:10155–10158

Chen Z, Cummins D, Reinecke BN, Clark E, Sunkara MK, Jaramillo TF (2011) Nano Lett 11:4168–4175

Sen UK, Mitra S (2012) RSC Adv 2:11123–11131

Wang M, Li G, Xu H, Qian Y, Yang J (2013) ACS Appl Mater Interfaces 5:1003–1008

Shi YM, Wang Y, Wong JI, Tan AYS, Hsu CL, Li LJ, Lu YC, Yang HY (2013) Sci Rep 3:2169

Stephenson T, Li Z, Olsen B, Mitlin D (2014) Energy Environ Sci 7:209–231

Ji X, Nazar LF (2010) J Mater Chem 20:9821–9826

Mabuchi A, Tokumitsu K, Fujimoto H, Kasuh T (1995) J Electrochem Soc 142:1041–1046

Andrews R, Jacques D, Qian D, Dickey EC (2001) Carbon 39:1681–1687

Endo M, Kim YA, Hayashi T, Yanagisawa T, Muramatsu H, Ezaka M, Terrones H, Terrones H, Dresselhaus MS (2003) Carbon 41:1941–1947

Ataca C, Şahin H, Aktürk E, Ciraci S (2011) J Phys Chem C 115:3934–3941

Ghorbani-Asl M, Enyashin AN, Kuc A, Seifert G, Heine T (2013) Phys Rev B 88(245440):1–7

Acknowledgments

We thank the “National Centre for Photovoltaic Research and Education (NCPRE),” Ministry of New and Renewable Energy, Govt. of India, and IRCC-IIT Bombay for financial support and infrastructural facilities. The authors are thankful to the members of SAIF, IIT Bombay, for their assistance with electron diffraction and FEG-SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 1687 kb)

Rights and permissions

About this article

Cite this article

Sen, U.K., Mitra, S. Improved electrode fabrication method to enhance performance and stability of MoS2-based lithium-ion battery anode. J Solid State Electrochem 18, 2701–2708 (2014). https://doi.org/10.1007/s10008-014-2518-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2518-8