Abstract

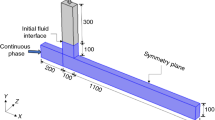

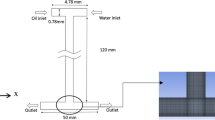

Researchers usually simplify their simulations by considering the Newtonian fluid assumption in microfluidic devices. However, it is essential to study the behavior of real non-Newtonian fluids in such systems. Moreover, using the external electric or magnetic fields in these systems can be very beneficial for manipulating the droplet size. This study considers the simulation of the process of non-Newtonian droplets’ formation under the influence of an external electric field. The novelty of this study is the use of a shear-thinning fluid as the droplet phase in this process, which has been less studied despite its numerous applications. The effects of an external electric field on this process are also investigated. Aqueous carboxymethyl cellulose (CMC) solution with different mass concentrations is selected as the non-Newtonian fluid of the droplet phase. The level set numerical method is used to analyze the formation of droplets in a T-junction. First, the effects of changing the key parameters such as the inlet velocities of phases, the concentration of the droplet phase, and the contact angle and the time of first droplet formation are investigated. The results indicate that as the concentration of the droplet phase increases, the diameter of the droplet decreases. Next, by applying a voltage difference to the system, an electric field is created inside the system. It is found that the stronger the electric field, the larger the droplet size due to the direction of electric forces applied to the interface of the droplet.

Similar content being viewed by others

References

Li, X., Chen, X.: Effect of interface wettability on the flow characteristics of liquid in smooth microchannels. Acta Mech. 230, 2111–2123 (2019). https://doi.org/10.1007/s00707-019-2371-z

Chatterjee, K., Staples, A.: Slip flow in a microchannel driven by rhythmic wall contractions. Acta Mech. 229, 4113–4129 (2018). https://doi.org/10.1007/s00707-018-2210-7

Whitesides, G.M.: The origins and the future of microfluidics. Nature 442, 368–373 (2006). https://doi.org/10.1038/nature05058

Ebadi, A., Toutouni, R., Farshchi Heydari, M.J., Fathipour, M., Soltani, M.: A novel numerical modeling paradigm for bio particle tracing in non-inertial microfluidics devices. Microsyst. Technol. (2019). https://doi.org/10.1007/s00542-018-4275-6

Pan, Z., Zhang, R., Yuan, C., Wu, H.: Direct measurement of microscale flow structures induced by inertial focusing of single particle and particle trains in a confined microchannel. Phys. Fluids. (2018). https://doi.org/10.1063/1.5048478

Huang, N.T., Hwong, Y.J., Lai, R.L.: A microfluidic microwell device for immunomagnetic single-cell trapping. Microfluid. Nanofluidics (2018). https://doi.org/10.1007/s10404-018-2040-x

Shen, F., Xue, S., Xu, M., Pang, Y., Liu, Z.M.: Experimental study of single-particle trapping mechanisms into microcavities using microfluidics. Phys. Fluids. (2019). https://doi.org/10.1063/1.5081918

Ichikawa, Y., Yamamoto, K., Yamamoto, M., Motosuke, M.: Near-hydrophobic-surface flow measurement by micro-3D PTV for evaluation of drag reduction. Phys. Fluids. (2017). https://doi.org/10.1063/1.5001345

Ageev, A.I., Osiptsov, A.N.: Slow viscous flow in a microchannel with similar and different superhydrophobic walls. J. Phys. Conf. Ser. (2018). https://doi.org/10.1088/1742-6596/1141/1/012134

Mohammadi, A., Floryan, J.M.: Mechanism of drag generation by surface corrugation. Phys. Fluids (2012). https://doi.org/10.1063/1.3675557

Javaherchian, J., Moosavi, A.: Pressure drop reduction of power-law fluids in hydrophobic microgrooved channels. Phys. Fluids. 31, 073106 (2019). https://doi.org/10.1063/1.5115820

Lin, X., Bao, F., Tu, C., Yin, Z., Gao, X., Lin, J.: Dynamics of bubble formation in highly viscous liquid in co-flowing microfluidic device. Microfluid. Nanofluidics (2019). https://doi.org/10.1007/s10404-019-2221-2

Hin, S., Paust, N., Keller, M., Rombach, M., Strohmeier, O., Zengerle, R., Mitsakakis, K.: Temperature change rate actuated bubble mixing for homogeneous rehydration of dry pre-stored reagents in centrifugal microfluidics. Lab Chip. 18, 362–370 (2018). https://doi.org/10.1039/c7lc01249g

Tan, H.: Numerical study of a bubble driven micromixer based on thermal inkjet technology. Phys. Fluids. (2019). https://doi.org/10.1063/1.5098449

Sakurai, R., Yamamoto, K., Motosuke, M.: Concentration-adjustable micromixers using droplet injection into a microchannel. Analyst. 144, 2780–2787 (2019). https://doi.org/10.1039/c8an02310g

Shamloo, A., Hassani-Gangaraj, M.: Investigating the effect of reagent parameters on the efficiency of cell lysis within droplets. Phys. Fluids 32, 62002 (2020). https://doi.org/10.1063/5.0009840

Bijarchi, M.A., Dizani, M., Honarmand, M., Shafii, M.B.: Splitting dynamics of ferrofluid droplet inside a microfluidic T-junction using a Pulse-Width Modulated magnetic field in Micro-magnetofluidics. Soft Matter (2020). https://doi.org/10.1039/D0SM01764G

Favakeh, A., Bijarchi, M.A., Shafii, M.B.: Ferrofluid droplet formation from a nozzle using alternating magnetic field with different magnetic coil positions. J. Magn. Magn. Mater. (2020). https://doi.org/10.1016/j.jmmm.2019.166134

Bijarchi, M.A., Shafii, M.B.: Experimental investigation on the dynamics of on-demand ferrofluid drop formation under a pulse-width-modulated nonuniform magnetic field. Langmuir 36, 7724–7740 (2020). https://doi.org/10.1021/acs.langmuir.0c00097

Shojaeian, M., Lehr, F.X., Göringer, H.U., Hardt, S.: On-demand production of femtoliter drops in microchannels and their use as biological reaction compartments. Anal. Chem. 91, 3484–3491 (2019). https://doi.org/10.1021/acs.analchem.8b05063

Nasiri, R., Shamloo, A., Akbari, J., Tebon, P., Dokmeci, M.R., Ahadian, S.: Design and simulation of an integrated centrifugal microfluidic device for CTCs separation and cell lysis. Micromachines (2020). https://doi.org/10.3390/mi11070699

Mai, T.D., Ferraro, D., Aboud, N., Renault, R., Serra, M., Tran, N.T., Viovy, J.L., Smadja, C., Descroix, S., Taverna, M.: Single-step immunoassays and microfluidic droplet operation: towards a versatile approach for detection of amyloid-β peptide-based biomarkers of Alzheimer’s disease. Sens. Actuators B Chem. 255, 2126–2135 (2018). https://doi.org/10.1016/j.snb.2017.09.003

Naghdloo, A., Ghazimirsaeed, E., Shamloo, A.: Numerical simulation of mixing and heat transfer in an integrated centrifugal microfluidic system for nested-PCR amplification and gene detection. Sens. Actuators B Chem. 283, 831–841 (2019). https://doi.org/10.1016/j.snb.2018.12.084

Sun, D., Cao, F., Cong, L., Xu, W., Chen, Q., Shi, W., Xu, S.: Cellular heterogeneity identified by single-cell alkaline phosphatase (ALP) via a SERRS-microfluidic droplet platform. Lab Chip. 19, 335–342 (2019). https://doi.org/10.1039/C8LC01006D

Amadeh, A., Ghazimirsaeed, E., Shamloo, A., Dizani, M.: Improving the performance of a photonic PCR system using TiO2 nanoparticles. J. Ind. Eng. Chem. (2020). https://doi.org/10.1016/j.jiec.2020.10.036

Cheow, L.F., Yobas, L., Kwong, D.L.: Digital microfluidics: droplet based logic gates. Appl. Phys. Lett. 90, 1–4 (2007). https://doi.org/10.1063/1.2435607

Zhang, Q., Zhang, M., Djeghlaf, L., Bataille, J., Gamby, J., Haghiri-Gosnet, A.M., Pallandre, A.: Logic digital fluidic in miniaturized functional devices: perspective to the next generation of microfluidic lab-on-chips. Electrophoresis 38, 953–976 (2017). https://doi.org/10.1002/elps.201600429

Teh, S.Y., Lin, R., Hung, L.H., Lee, A.P.: Droplet microfluidics. Lab Chip. 8, 198–220 (2008). https://doi.org/10.1039/b715524g

Cedillo-Alcantar, D.F., Han, Y.D., Choi, J., Garcia-Cordero, J.L., Revzin, A.: Automated droplet-based microfluidic platform for multiplexed analysis of biochemical markers in small volumes. Anal. Chem. 91, 5133–5141 (2019). https://doi.org/10.1021/acs.analchem.8b05689

Geng, H., Feng, J., Stabryla, L.M., Cho, S.K.: Dielectrowetting manipulation for digital microfluidics: creating, transporting, splitting, and merging of droplets. Lab Chip. 17, 1060–1068 (2017). https://doi.org/10.1039/c7lc00006e

Teo, A.J.T., Li, K.H.H., Nguyen, N.T., Guo, W., Heere, N., Xi, H.D., Tsao, C.W., Li, W., Tan, S.H.: Negative pressure induced droplet generation in a microfluidic flow-focusing device. Anal. Chem. 89, 4387–4391 (2017). https://doi.org/10.1021/acs.analchem.6b05053

Xu, J.H., Li, S.W., Tan, J., Luo, G.S.: Correlations of droplet formation in T-junction microfluidic devices: from squeezing to dripping. Microfluid. Nanofluidics 5, 711–717 (2008). https://doi.org/10.1007/s10404-008-0306-4

De Menech, M., Garstecki, P., Jousse, F., Stone, H.A.: Transition from squeezing to dripping in a microfluidic T-shaped junction. J. Fluid Mech. 595, 141–161 (2008)

Liu, H., Zhang, Y.: Droplet formation in a T-shaped microfluidic junction. J. Appl. Phys. 106, 34906 (2009). https://doi.org/10.1063/1.3187831

Christopher, G.F., Noharuddin, N.N., Taylor, J.A., Anna, S.L.: Experimental observations of the squeezing-to-dripping transition in T-shaped microfluidic junctions. Phys. Rev. E. 78, 36317 (2008). https://doi.org/10.1103/PhysRevE.78.036317

Jullien, M.C., Tsang Mui Ching, M.J., Cohen, C., Menetrier, L., Tabeling, P.: Droplet breakup in microfluidic T-junctions at small capillary numbers. Phys. Fluids. 21, 1–7 (2009). https://doi.org/10.1063/1.3170983

Sivasamy, J., Wong, T.N., Nguyen, N.T., Kao, L.T.H.: An investigation on the mechanism of droplet formation in a microfluidic T-junction. Microfluid. Nanofluidics 11, 1–10 (2011). https://doi.org/10.1007/s10404-011-0767-8

Nekouei, M., Vanapalli, S.A.: Volume-of-fluid simulations in microfluidic T-junction devices: influence of viscosity ratio on droplet size. Phys. Fluids (2017). https://doi.org/10.1063/1.4978801

Zeng, W., Li, S., Fu, H.: Modeling of the pressure fluctuations induced by the process of droplet formation in a T-junction microdroplet generator. Sens. Actuators A Phys. 272, 11–17 (2018). https://doi.org/10.1016/j.sna.2018.01.013

Bashir, S., Rees, J.M., Zimmerman, W.B.: Simulations of microfluidic droplet formation using the two-phase level set method. Chem. Eng. Sci. 66, 4733–4741 (2011). https://doi.org/10.1016/j.ces.2011.06.034

Soh, G.Y., Yeoh, G.H., Timchenko, V.: Numerical investigation on the velocity fields during droplet formation in a microfluidic T-junction. Chem. Eng. Sci. 139, 99–108 (2016). https://doi.org/10.1016/j.ces.2015.09.025

Gu, Z., Liow, J.L.: Micro-droplet formation with non-Newtonian solutions in microfluidic T-junctions with different inlet angles. In: 2012 7th IEEE International Conference on Nano/Micro Engineering Molecular System. NEMS 2012. pp 423–428 (2012). https://doi.org/10.1109/NEMS.2012.6196809

Nooranidoost, M., Izbassarov, D., Muradoglu, M.: Droplet formation in a flow focusing configuration: effects of viscoelasticity. Phys. Fluids. (2016). https://doi.org/10.1063/1.4971841

Chiarello, E., Gupta, A., Mistura, G., Sbragaglia, M., Pierno, M.: Droplet breakup driven by shear thinning solutions in a microfluidic T-junction. Phys. Rev. Fluids. 2, 1–13 (2017). https://doi.org/10.1103/PhysRevFluids.2.123602

Liang, D., Ma, R., Fu, T., Zhu, C., Wang, K., Ma, Y., Luo, G.: Dynamics and formation of alternating droplets under magnetic field at a T-junction. Chem. Eng. Sci. 200, 248–256 (2019). https://doi.org/10.1016/j.ces.2019.01.053

Sahore, V., Doonan, S.R., Bailey, R.C.: Droplet microfluidics in thermoplastics: device fabrication, droplet generation, and content manipulation using integrated electric and magnetic fields. Anal. Methods. 10, 4264–4274 (2018). https://doi.org/10.1039/c8ay01474d

Chen, I.M., Tsai, H.H., Chang, C.W., Zheng, G., Su, Y.C.: Electric-field triggered, on-demand formation of sub-femtoliter droplets. Sens. Actuators B Chem. 260, 541–553 (2018). https://doi.org/10.1016/j.snb.2017.12.152

Nhu, C.N., Thu, H.N., Le Van, L., Duc, T.C., Dau, V.T., Bui, T.T.: Study on flow-focusing microfluidic device with external electric field for droplet generation. In: Fujita, H., Nguyen, D.C., Vu, N.P., Banh, T.L., Puta, H.H. (eds.) Advances in Engineering Research and Application, pp. 553–559. Springer International Publishing, Cham (2019)

Li, Y., Jain, M., Ma, Y., Nandakumar, K.: Control of the breakup process of viscous droplets by an external electric field inside a microfluidic device. Soft Matter 11, 3884–3899 (2015). https://doi.org/10.1039/c5sm00252d

Yang, C., Qiao, R., Mu, K., Zhu, Z., Xu, R.X., Si, T.: Manipulation of jet breakup length and droplet size in axisymmetric flow focusing upon actuation. Phys. Fluids 31, 091702 (2019). https://doi.org/10.1063/1.5122761

Josephides, D.N., Sajjadi, S.: Increased drop formation frequency via reduction of surfactant interactions in flow-focusing microfluidic devices. Langmuir 31, 1218–1224 (2015). https://doi.org/10.1021/la504299r

Van Nguyen, H., Nguyen, H.Q., Nguyen, V.D., Seo, T.S.: A 3D printed screw-and-nut based droplet generator with facile and precise droplet size controllability. Sens. Actuators B Chem. 296, 126676 (2019). https://doi.org/10.1016/j.snb.2019.126676

Tóth, A.B., Holczer, E., Hakkel, O., Tóth, E.L., Iván, K., Fürjes, P.: Modelling and characterisation of droplet generation and trapping in cell analytical two-phase microfluidic system. Proceedings. 1, 526 (2017). https://doi.org/10.3390/proceedings1040526

Yan, Q., Xuan, S., Ruan, X., Wu, J., Gong, X.: Magnetically controllable generation of ferrofluid droplets. Microfluid. Nanofluidics. 19, 1377–1384 (2015). https://doi.org/10.1007/s10404-015-1652-7

Zhang, S., Guivier-Curien, C., Veesler, S., Candoni, N.: Prediction of sizes and frequencies of nanoliter-sized droplets in cylindrical T-junction microfluidics. Chem. Eng. Sci. 138, 128–139 (2015). https://doi.org/10.1016/j.ces.2015.07.046

Chen, H., Man, J., Li, Z., Li, J.: Microfluidic generation of high-viscosity droplets by surface-controlled breakup of segment flow. ACS Appl. Mater. Interfaces. 9(21059), 21064 (2017). https://doi.org/10.1021/acsami.7b03438

Prileszky, T.A., Ogunnaike, B.A., Furst, E.M.: Statistics of droplet sizes generated by a microfluidic device. AIChE J. 62, 2923–2928 (2016). https://doi.org/10.1002/aic.15246

Wong, V.L., Loizou, K., Lau, P.L., Graham, R.S., Hewakandamby, B.N.: Numerical simulation of the effect of rheological parameters on shear-thinning droplet formation. Am. Soc. Mech. Eng. Fluids Eng. Div. FEDSM (2014). https://doi.org/10.1115/FEDSM2014-21363

Allgén, L.-G., Roswall, S.: A dielectric study of a carboxymethylcellulose in aqueous solution. J. Polym. Sci. 12, 229–236 (1954). https://doi.org/10.1002/pol.1954.120120119

Nabizadeh, A., Hassanzadeh, H., Sharifi, M., Keshavarz Moraveji, M.: Effects of dynamic contact angle on immiscible two-phase flow displacement in angular pores: a computational fluid dynamics approach. J. Mol. Liq. (2019). https://doi.org/10.1016/j.molliq.2019.111457

Wang, X.D., Lee, D.J., Peng, X.F., Lai, J.Y.: Spreading dynamics and dynamic contact angle of non-Newtonian fluids. Langmuir 23, 8042–8047 (2007). https://doi.org/10.1021/la0701125

Šikalo, Š, Wilhelm, H.D., Roisman, I.V., Jakirlić, S., Tropea, C.: Dynamic contact angle of spreading droplets: experiments and simulations. Phys. Fluids. 17, 1–13 (2005). https://doi.org/10.1063/1.1928828

Jangir, P., Jana, A.K.: CFD simulation of droplet splitting at microfluidic T-junctions in oil–water two-phase flow using conservative level set method. J. Braz. Soc. Mech. Sci. Eng. 41, 1–16 (2019). https://doi.org/10.1007/s40430-019-1569-2

Li, L., Zhang, C.: Electro-hydrodynamics of droplet generation in a co-flowing microfluidic device under electric control. Colloids Surf. A Physicochem. Eng. Asp. 586, 124258 (2020). https://doi.org/10.1016/j.colsurfa.2019.124258

Sheng, P., Qian, T., Wang, X.: Hydrodynamic boundary condition at the fluid-solid interface. Int. J. Mod. Phys. B. 21, 4131–4143 (2007). https://doi.org/10.1142/S0217979207045311

Osher, S., Sethian, J.A.: Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 79, 12–49 (1988). https://doi.org/10.1016/0021-9991(88)90002-2

Wong, V.L., Loizou, K., Lau, P.L., Graham, R.S., Hewakandamby, B.N.: Numerical studies of shear-thinning droplet formation in a microfluidic T-junction using two-phase level-SET method. Chem. Eng. Sci. 174, 157–173 (2017). https://doi.org/10.1016/j.ces.2017.08.027

Lan, W., Li, S., Wang, Y., Luo, G.: CFD simulation of droplet formation in microchannels by a modified level set method. Ind. Eng. Chem. Res. 53, 4913–4921 (2014). https://doi.org/10.1021/ie403060w

Olsson, E., Kreiss, G.: A conservative level set method for two phase flow. J. Comput. Phys. 210, 225–246 (2005). https://doi.org/10.1016/j.jcp.2005.04.007

Harten, A.: The artificial compression method for computation of shocks and contact discontinuities. I. Single conservation laws. Commun. Pure Appl. Math. 30, 611–638 (1977). https://doi.org/10.1002/cpa.3160300506

Zare, Y., Park, S.P., Rhee, K.Y.: Analysis of complex viscosity and shear thinning behavior in poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes biosensor based on Carreau-Yasuda model. Results Phys. 13, 102245 (2019). https://doi.org/10.1016/j.rinp.2019.102245

Van Der Graaf, S., Nisisako, T., Schroën, C.G.P.H., Van Der Sman, R.G.M., Boom, R.M.: Lattice Boltzmann simulations of droplet formation in a T-shaped microchannel. Langmuir 22, 4144–4152 (2006). https://doi.org/10.1021/la052682f

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amiri, N., Honarmand, M., Dizani, M. et al. Shear-thinning droplet formation inside a microfluidic T-junction under an electric field. Acta Mech 232, 2535–2554 (2021). https://doi.org/10.1007/s00707-021-02965-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-02965-y