Summary

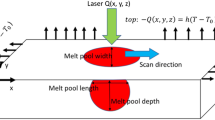

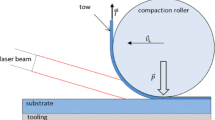

Residual stress induced deformations are a major cause of loss in tolerances in Solid Freeform Fabrication processes employing direct metal deposition. In this paper, a 2D finite element thermo-mechanical model is presented to predict the residual stress induced deformations with application to processes where material is added using a distributed, moving heat source. A sequentially coupled thermo-mechanical analysis is performed using a kinematic thermal model and plane strain structural model. Temperature dependent material properties are used with the material modeled as elastic perfectly plastic. An interpass cooling between successive depositions is employed in accordance to the requirement of experiment. The simulation results are compared with experimental data for successive sections along deposition and it is found that, with the exception of deposition center and plate edges, the two are in very good agreement. The error at plate edges can be as high as 45%, and the reason is that a 2D model cannot capture the effect of plate bolting accurately. A case of continuous deposition, without interpass cooling, has been compared with the base case of employing interpass cooling. It has been found that continuous deposition results in higher preheating of the substrate which consequently reduces the deformation.

Similar content being viewed by others

References

Y. Zhang P. Yiwei Y. Chen A. Male (2002) ArticleTitleAutomated system for welding based rapid prototyping Mechatronics 12 37–53 Occurrence Handle10.1016/S0957-4158(00)00064-7

Merz, R.: Shape deposition manufacturing. PhD. Diss. Vienna University of Technology, TU Wien 1994.

J. Spencer P. Dickens C. Wykes (1998) ArticleTitleRapid prototyping of metal parts by 3D welding Inst. Mech. Engng. 212B 175–181 Occurrence Handle10.1243/0954405981515590

Prodan, T., Amon, C., Finger, S., Weiss, L: Shape deposition manufacturing for embedding electronics and building injection molding tools. Department of Mechanical Engineering, ICES, Carnegie Mellon University, Pittsburgh, Pennsylvania 1998.

K. Schmaltz N. Leoni P. Padmanabhan C. Amon S. Finger L. Weiss (1997) ArticleTitleInvestigation of transport phenomena in microcasting shape deposition manufacturing via experiments designed using optimal sampling Symp. Manufacturing Mater. Process. ASME-HTD 347 241–250

Jayanthi, S., Keefe, M., Gargiulo, E.: Studies in stereolithography: influence of process parameters on curl distortion in photopolymer models. Proc. Solid Freeform Fabrication Symp., pp. 250–258, Austin, Texas 1994.

Ullett, J., Chartoff, R., Lightman, A., Murphy, J., Li, J.: Reducing warpage in stereolithography through novel draw styles. Proc. Solid Freeform Fabrication Symp., pp. 242–249, Austin, Texas 1994.

Jacobs, P.: Rapid prototyping and manufacturing: fundamentals of stereolithography. SME 1996.

N. Karapatis Y. Guidoux P. Gygax R. Glardon (1998) Thermal behavior of parts made by direct metal laser sintering D. L. Bourell J. J. Beaman R. H. Crawford H. L. Marcus J. W. Barlow (Eds) Proc. Solid Freeform Fabrication Symp. Texas Austin 79–87

P. Dickens R. Cobb I. Gibson M. Pridham (1993) ArticleTitleRapid prototyping using 3D welding J. Des. Manufacturing 1 39–44

K. Kalligarakis Mellor (1992) ArticleTitleDouble spiral overlay welding – an alternative to single and multilayer techniques Welding Metal Fabrication 60 277–280

M. P. Mughal H. Fawad R. Mufti (2006) ArticleTitleNumerical thermal analysis to study the effect of static contact angle on the cooling rate of molten metal droplet Numer. Heat Transf. A 49 IssueID1 95–107 Occurrence Handle10.1080/10407780500283382

M. P. Mughal H. Fawad R. Mufti (2006) ArticleTitleParametric thermal analysis of molten metal droplet as applied to layered manufacturing J. Heat Mass Transfer 42 IssueID3 226–237

R. Chin J. Beuth C. Amon (1996) ArticleTitleThermo mechanical modeling of molten metal droplet solidification as applied to layered manufacturing Mech. Mater. 24 257–271 Occurrence Handle10.1016/S0167-6636(96)00037-3

R. Chin J. Beuth C. Amon (2001) ArticleTitleSuccessive deposition of metals in SFF processes, part 2: Thermo mechanical models of adjacent droplet J. Manufacturing Sci. Engng. 123 632–638 Occurrence Handle10.1115/1.1380200

R. Chin J. Beuth C. Amon (2001) ArticleTitleSuccessive deposition of metals in SFF processes, part 1: Thermo mechanical models of layers and droplet columns J. Manufacturing Sci. Engng. 123 623–631 Occurrence Handle10.1115/1.1380199

Nickel, A.: Analysis of thermal stresses in shape deposition manufacturing of metal parts. Ph.D. Thesis, Stanford University 1999.

A. Nickel D. Barnett F. Prinz (2001) ArticleTitleThermal stresses and deposition patterns in layered manufacturing Mat. Sci. Engng. A317 59–64 Occurrence Handle10.1016/S0921-5093(01)01179-0

N. Klingbeil R. Chin J. Beuth C. Amon (1998) Measurement and modeling of residual stresses induced warping in direct metal deposition processes D. L. Bourell J. J. Beaman R. H. Crawford H. L. Marcus J. W. Barlow (Eds) Proc. Solid Freeform Fabrication Symp. Texas Austin 367–374

Fawad, H., Mughal, M. P., Siddique, M.: Finite element simulation of welding based deposition process as applied to layered manufacturing: Thermal model. Int. Mechanical Engineering Conf. and Exhibition 2004 (IMECE2004), IMEC04-5062, pp. 656–673, 2004.

J. Goldak M. Bibby J. Moore R. House B. Patel (1986) ArticleTitleComputer modeling of heat flow in welds Metall Trans. B 15 587–600

Andersen, L. F.: Residual stresses and deformations in steel structures. Ph.D. Thesis, Technical University of Denmark 2000.

L. Lindgren (2001) ArticleTitleFinite element modeling and simulation of welding, part 1: Increased complexity J. Thermal Stresses 24 141–192 Occurrence Handle10.1080/01495730150500442

D. Rosenthal (1946) ArticleTitleThe theory of moving source of heart and its application to metal transfer Trans. ASME 43 IssueID11 849–866

Debiccari: Control of distortion and residual stresses in girth welded pipe, PhD. Thesis, Department of Mechanical Engineering, M.I.T 1986.

V. Kamala J. A. Goldak (1993) ArticleTitleError due to two-dimensional approximation in heat transfer analysis of welds Welding J. 72 IssueID9 440s–446s

J. Goldak A. Chakravarti M. Bibby (1984) ArticleTitleA new finite element model for heat sources Metall. Trans. B 15 299–305

M. Abid M. Siddique (2005) ArticleTitleFinite-element simulation of tack welds in girth welding of a pipe-flange joint Acta Mech. 178 53–64 Occurrence Handle10.1007/s00707-005-0241-3 Occurrence Handle1116.74422

L. Lindgren (2001) ArticleTitleFinite element modeling and simulation of welding, part 2: Improved material modeling J. Thermal Stresses 24 195–231 Occurrence Handle10.1080/014957301300006380

Holman, J.: Heat transfer, 6th international edn, pp. 55–57. Singapore: McGraw Hill 1986.

K. Masubuchi (1980) Analysis of welded structures. International Series on Materials Science and Technology, Vol. 33, 1st edn Pergamon Press New York

McDill, J. M. J., Oddy, A. S., Goldak, J. A.: Comparing 2-D plane strain and 3-D analyses of residual stresses in welds. Proc. of 3rd Int. Conf. on Trends in Welding Research, pp. 105–108, Gatlinburg, Tennessee 1992.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mughal, M.P., Fawad, H. & Mufti, R. Finite element prediction of thermal stresses and deformations in layered manufacturing of metallic parts. Acta Mechanica 183, 61–79 (2006). https://doi.org/10.1007/s00707-006-0329-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-006-0329-4