Summary

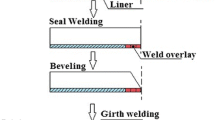

Welding deformations play an important role in sealing capabilities and service life of welded pipe-flange joints. A numerical procedure for modeling of tack welds in girth butt-welding of such joints is of vital importance for the prediction of transverse shrinkage and flange face deformation, which is directly related to the joint sealing capability. This paper presents a 3-D finite element simulation of a pipe-flange joint to describe the numerical procedure for modeling of tack welds in circumferential joints. Sequentially coupled nonlinear transient thermo-mechanical analysis is performed to simulate Metal Inert Gas (MIG) welding. Single pass butt weld geometry with single “V” for 100 mm nominal diameter pipe with same sized weld neck type ANSI flange of class no. 300 is used. Temperature dependent material properties are used and deposition of filler metal is obtained by element birth and death feature. The peak temperature of the tack during the butt-welding of the tacked model is concluded a key parameter for numerical prediction of deformations, whereas tack temperature has negligible effect on the residual stresses.

Similar content being viewed by others

References

Abid, M., Nash, D. H.: Risk assessment studies for gasketed and non-gasketed bolted pipe joints. Int. Pipeline Conf. (IPC2002), Calgary Canada, September 29–October 3, 2002. Proc. IPC2002/IPC-27386, pp. 1–11 (2002).

Nash, D. H., Abid, M.: Surface sensitivity study of non-gasketed flange joint. J. Process Mech. Engng., Part-E (E4) 218, 205–212 (2004).

Rybicki, E., Schmueser, D., Stonesifer, R., Groom, J., Mishaler, H.: A finite element model for residual stresses and deflections in girth-butt welded pipes. ASME J. PVT 100, 256–262 (1978).

Rybicki, E., McGuire, P., Merrick, E., Wert, J.: The effect of pipe thickness on residual stresses due to girth welds. ASME J. PVT 104, 204–209 (1982).

Rybicki, E., Stonesifer, R.: Computation of residual stresses due to multipass welds in piping system. ASME J. PVT 101, 149–154 (1979).

Brickstad, B., Josefson, B. L.: A parametric study of residual stresses in multi-pass butt-welded stainless steel pipes. Int. J. PVP 75, 11–25 (1998).

Karlsson, L., Jonsson, M., Lindgren, L. E., Nasstrom, M., Troive, L.: Residual stresses and deformations in a welded thin-walled pipe. In: ASME Pressure Vessels and Piping Conf. 1989 (Rybicki, E., Shiratori, E., Widera, G.E.O., Miyoshi, T., eds.), pp. 7–14. Weld Residual Stresses and Plastic Deformation, Honolulu, Hawaii 1989. New York: PVP, vol. 173, 1989.

Dong, Y., Hong, J., Tasi, C., Dong, P.: Finite element modeling of residual stresses in austenitic stainless steel pipe girth welds. AWS Welding J. (Welding Res. Suppl.), 442-s–449-s (1997).

Karlsson, R. I., Josefson, B. L.: Three-dimensional finite element analysis of temperature and stresses in single-pass butt-welded pipe. ASME J. PVT 112, 76–84 (1990).

Fricke, S., Keim, E., Schmidt, J.: Numerical weld modeling – a method for calculating weld-induced residual stresses. Nuclear Engng. Des. 206, 139–150 (2001).

Siddique, M., Abid, M., Junejo, H. F., Mufti, R. A.: 3-D finite element simulation of welding residual stresses in pipe-flange joints: effect of welding parameters. Residual Stresses VII, Material Science Forum 490–491, pp. 79–84, 2005 (Denis, S., Hanabusa, T., Baoping, B., Eric Mittemeijer, E., Nan, J., Noyan, I.C., Scholtes, B., Tanaka, K., Xu, K., eds.), Proc. ICRS-7, X’ian, China, 14–17 June 2004.

Jonsson, M., Karlsson, L., Lindgren, L. E.: Simulation of tack welding procedures in butt joint welding of plates. AWS Welding J. Welding Research Suppl., 296-s–301-s (1995).

Jonsson, M., Karlsson, L., Lindgren, L. E.: Plate motion and thermal stresses in root-bead butt-welding of plates. In: Numerical methods in heat transfer (Lewis, R.W., Morgan, K., eds.). New York: Wiley 1995.

Shibahara, M., Serizawa, H., Murakawa, H.: Finite-element analysis using interface elements for predicting deformation during butt welding considering root gap and tack welds. Trans. JWRI 31, 63–70 (2002).

Wang, X., Hoffmann, C., Hsueh, C., Sarma, G., Hubbard, C.: Influence of residual stresses on thermal expansion behavior. Appl. Phys. Lett. 75, 3294–3296 (1999).

Andersen, L.: Residual stresses and deformations in steel structures. Ph.D. thesis, Technical University of Denmark, 2000.

ANSYS User’s Manual, SAS IP inc., 1998.

Lindgren, L. E., Runnemalm, H., Näsström, M.: Simulation of multipass welding of a thick plate. Int. J. Numer. Meth. Engng. 44, 1301–1316 (1999).

Siddique, M., Abid, M., Mufti, R. A.: Simulation of welding distortions and residual stresses in pipe-flange joint using finite element technique: comparison of 2-D and 3-D models. Proc. of IMEC2004 (Int. Mech. Engin. Conf. and Expo), Kuwait, December 5–8 (2004).

Goldak, J., Chakravarti, A., Bibby, M.: A new finite element model for welding heat sources. Metall. Trans. B, 15B, 299–305 (1984).

Goldak, J., Bibby, M., Moore, J., House, R., Patel, B.: Computer modeling of heat flow in welds. Metall. Trans. B, 17B, 587–600 (1985).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abid, M., Siddique, M. Finite-element simulation of tack welds in girth welding of a pipe-flange joint. Acta Mechanica 178, 53–64 (2005). https://doi.org/10.1007/s00707-005-0241-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-005-0241-3