Abstract

Abstract

In this paper I summarize our recent investigations (Park and Kim, Phys Chem C 111:14903, 2007; Solid State Ionics 179:1329, 2008) on the origin of the grain-boundary resistance in a doped LaGaO3, a perovskite-structured solid electrolyte. The partial electronic and ionic resistances of the bulk and the grain boundaries, as well as the total resistance, in 1 mol% Sr-doped LaGaO3 were measured separately by means of a dc-polarization method and ac-impedance spectroscopy. Both of the partial resistances at the grain boundaries were greater than the bulk counterparts, indicating that the grain boundaries impede the ionic as well as the electronic transport in this material. The transference number of the partial electronic conductivity at the grain boundary was however greater than that in the bulk. This fact strongly suggests that both electronic and ionic charge carriers deplete at the grain boundaries to form the space-charge zones and that the grain-boundary cores in this material are positively charged. In light of the fact that the effective charge of the oxygen vacancy (+2) is greater than that of the electron hole (+1), the oxygen vacancies deplete more sharply in the space-charge zones compared to the electron holes such that the grain boundaries become more mixed conducting relative to the bulk. These observations verify that the electrical conduction across the grain-boundaries in 1 mol% Sr-doped LaGaO3 is governed by the space charge.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The physical behavior of grain boundaries (i.e., interfaces between crystallites, namely grains, in polycrystalline ceramics) differs from that of the bulk due to their structural deviation from the crystal interior. In the past decade, the electrical nature of grain boundaries relative to the bulk has attracted considerable attention as “size effects” [1] on the conductivity have become one of the main foci of research interest, particularly in the field of solid state ionics. Reducing the size of the grains enhances the geometric contribution of the grain boundaries to the total volume of the polycrystalline ceramic such that the overall electrical properties may be governed by the property associated with the grain boundaries when the grain size is sufficiently small (typically less than few tens of nanometers). The overall conductivity of a material with a higher density of grain boundaries can then be enhanced if the grain boundaries serve as highly conducting paths.

Solid electrolytes (SEs) [2] are virtually pure ionic conductors that serve as a key component in electrochemical devices such as solid oxide fuel cells (SOFCs) [3, 4]. Among them, doped zirconia and ceria, fast oxygen-ionic conductors with a fluorite structure, have almost exclusively been employed as SEs for SOFC applications owing to their relatively high ionic conductivity at elevated temperatures [2–4]. However, these SEs present sufficiently high ionic conductivity only at very high temperatures, leading to the high operating temperature (>800 °C) of the SOFCs. It is desirable to lower the operating temperature down to the intermediate temperature (IT) range (500–700 °C or even less) to ameliorate the problems associated with high-temperature operation, such as long-term durability of the cells and cost [4]. Lower-temperature operation, on the other hand, requires enhanced conductance in the SEs.

Nanocrystalline SEs have been the center of attention for over a decade owing to their potential for use in the IT-SOFCs. However, it was found that the grain boundaries in fluorite-structured SEs inherently rather impede oxygen-ionic transport in the materials, and this issue worsens at lower temperatures. Hence, the electrical nature of the grain boundaries in those SEs has been intensively explored during the past decade and the intrinsic origins of the grain boundary resistance are now relatively well understood [5–9]: at the grain boundaries, the oxygen vacancies (V ••O ) deplete to form space-charge zones [10, 11] in the vicinity of the grain-boundary core, leading to high resistance to oxygen-ionic transport across them. The excess positive charge formed in the grain-boundary core is responsible for the depletion of V ••O in the space-charge zones.

Doped LaGaO3 is a perovskite-structured oxygen-ionic conductor that presents a conductivity higher than the conductivities of the fluorite-structured SEs at lower temperatures [12], and is thus considered a SE for IT-SOFC applications. However, the electrical nature of the grain boundaries in this SE resembles that in fluorite-structured SEs in that the grain boundaries block the oxygen-ionic transport. In view of the relatively recent discovery of this SE, research on it has focused almost exclusively on its bulk properties, while little attention has been paid to the grain boundaries to date. The chief question about the blocking nature of the grain boundaries in this perovskite-structured SE is whether the intrinsic cause of the grain-boundary resistance is the space charge, as seen in the fluorite-structured SEs.

In this contribution I summarize our recent investigations [13, 14] on the influence of the space-charge effects on the grain-boundary conduction in 1 mol% Sr-doped LaGaO3 (LSGO), which we selected as a model system. As will be presented below, the results obtained from dc-polarization and ac-impedance measurements clearly demonstrate that both V ••O and the electron holes (h·) (i.e., the majority charge carriers in LSGO at the oxygen partial pressure, \( P_{{{\text{O}}_{2} }} \), of concern) deplete at the grain boundaries to form space-charge zones, leading to grain boundaries with high resistance to both ionic and the electronic transport across them.

Results and discussion

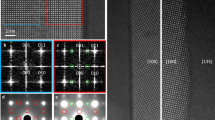

Figure 1 shows a high-resolution transmission electron microscope (HR-TEM) image of dense (>95%) LSGO used for electrical measurements. The grain boundaries appear to be free of pores as well as insulating amorphous phases which are often responsible for the high resistance to the ionic current at the grain boundaries observed in impure SEs. The Ca and Si contents (typical sources of the amorphous phases) in the sample, measured using an inductively coupled plasma (ICP) technique, were below the detection limit (≪100 ppm), consistent with the TEM results.

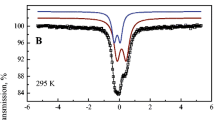

The resistances under different \( P_{{{\text{O}}_{2} }} \) in LSGO were measured using both ac-impedance spectroscopy and a dc-measurement technique. The advantage of the ac over the dc measurements is that the ac technique allows one to measure the local resistance (e.g., in the bulk and the grain boundary) separately. Figure 2 shows an ac-impedance spectrum (i.e., a Nyquist plot) measured from LSGO in O2 at 400 °C (see red symbols), which consists of a relatively tiny (see also the inset in Fig. 2) arc that appears at higher frequencies and a large semicircular arc that subsequently appears at lower frequencies of concern (namely arc 1 and arc 2, respectively). Arc 1 appears to be incomplete. The best fits for arcs 1 and 2 using an equivalent circuit consisting of two parallel RQ elements in series [i.e., (R 1 Q 1 )(R 2 Q 2 ) where R and Q denote resistance and a constant-phase element, respectively] are indicated as solid lines in Fig. 2. The dielectric constant of ~30 at 400 °C estimated from C 1 (=(R 1−n1 Q 1)1/n) agrees well with that of pure LaGaO3 (~25) [15], suggesting that arcs 1 and 2 represent the bulk and the grain boundaries, respectively, as usual. (Figure 2 also shows an indication of a third arc, corresponding to the electrode resistance, which appears at at even lower frequency range than the frequency range of concern in this study; however, a discussion of the electrode resistance is beyond the scope of this paper.) Note that the grain boundaries are almost exclusively responsible for the overall resistance in LSGO at 400 °C. Figure 2 also shows a spectrum measured under N2.

It is interesting to note that arc 2 varies with varying ambient \( P_{{{\text{O}}_{2} }} \) , while arc 1 remains unchanged. As mentioned above, the majority ionic and electronic charge carriers in LSGO under oxidizing conditions (e.g., under O2) are V ••O and h·, respectively. If electric conduction in LSGO is predominantly controlled by V ••O , the resistance should be independent of \( P_{{{\text{O}}_{2} }} \) since the number of V ••O in the material is determined by the amont of dopant. Hence, the fact that only the grain-boundary resistance depends on the ambient \( P_{{{\text{O}}_{2} }} \) implies that the electronic contribution to grain-boundary conduction is greater than that the electronic contribution to the bulk conduction. In other words, the electronic transference number (t j = σ j /∑ k σ k ) at the grain boundaries (t el,gb) is greater than that in the bulk (t el,∞).

According to Eq. 1, at equilibrium, the local concentration of defect j in the vicinity of the grain-boundary core is determined by the electrical potential of the grain-boundary core:

where Δϕ(x) is the electrical potential relative to the bulk (subscript ∞; i.e., Δϕ(x) = ϕ(x) − ϕ(∞)). The symbols z, e, k B and T denote the charge number, elementary charge, Boltzmann’s constant and temperature, respectively. Both V ••O and h· thus deplete in the vicinity of the grain-boundary core to form space-charge zones if ϕ(0) > 0. Furthermore, V ••O should deplete more sharply than h· (see Eq. 1), as illustrated qualitatively in Fig. 3, since the effective charge of V ••O (+2) is greater than that of h· (+1), leading to a greater t el,gb than t el,∞. Therefore, Fig. 2 strongly suggests that the grain-boundary conduction in LSGO is controlled by the space charge. In order to verify this speculation, one should measure the partial ionic and electronic conductivities at the grain boundaries and in the bulk separately to check whether t el,gb is in fact greater than t el,∞.

Figure 4 presents the current (I)–voltage (U) characteristics measured from an ion-blocking dc-polarization cell (see the inset in Fig. 4) at 475 °C in air. Dc-polarization methods [16, 17] are considered to be one of the most effective means to measure the partial conductivities separately. Prior to measuring the I–U characteristics, the ion-blocking cell was polarized at a constant applied voltage of 5 mV. During polarization, the initial current (~155 nA) rapidly dropped to reach an equilibrium value of 30 nA within 1000 s. This fact ensures that the ionic current is effectively blocked at the ion-blocking electrode. Figure 4 shows that the current linearly increases with increasing applied voltage up to ~25 mV and then starts to deviate from linear behavior to show the characteristic nonlinear I–U relation for a blocking cell as the voltage further increases. In light of the fact that the concentration of electrons in LSGO in the \( P_{{{\text{O}}_{2} }} \) range of concern is negligibly small compared to that of h· (i.e., h· is almost exclusively responsible for the electronic current in LSGO, if not entirely), one can estimate the partial electronic conductivity (σ el = 1/R el(d/A), where d and A are the distance between the electrodes and the area of the electrode, and R denotes resistance) by directly measuring R el in the ohmic region (<25 mV).

It is also necessary for one to selectively measure the local σ el in the bulk and at the grain boundaries to eventually estimate both t el.gb and t el,∞. This is actually possible owing to the fact that the activation energy of R gb (~0.7 eV) estimated from the Arrhenius plots (not shown here) was found to be significantly higher than that of R ∞ (~1.4 eV) in LSGO [13, 14]. At relatively high temperatures (>750 °C), the resistance in LSGO is predominantly determined by R ∞ (i.e., R dc = R ∞ + R gb ≈ R ∞ since R ∞ ≫ R gb), while R gb is responsible for the resistance (i.e., R dc = R ∞ + R gb ≈ R gb since R ∞ ≪ R gb) at lower temperatures (<500 °C) [14]. Note that the electrodes of the sample were modified in such a way that the resistance at the electrodes is negligibly small at all temperatures of concern [14] (also see “Experimental” for details). By measuring R el in different temperature regions, one can thus measure R el,∞ and R el,gb selectively and thus t el,∞ and t el,gb.

Figure 5 shows t el,gb and t el,∞ estimated at different temperatures. The t el,gb/t el,∞ measured at lower/higher temperatures was extrapolated to higher/lower temperatures for direct comparison. As is clear from Fig. 5, t el,gb is greater than t el,∞ as expected from Fig. 2 at all temperatures of concern. Therefore, Fig. 5 verifies that the high grain-boundary resistance to oxygen-ionic transport observed in LSGO is due to the depletion of V ••O to form space charge zones at the grain boundaries. Space-charge-controlled grain-boundary conduction in perovskites has been previously reported for dielectric oxides (e.g., acceptor-doped SrTiO3), and intensively studied by Waser, Maier and their coworkers [18–23 and references cited therein]. At the grain boundaries in these materials, both V ••O and h· were found to be depleted, forming space-charge zones similar to those we observed in LSGO.

A more quantitative and comprehensive analysis of the influence of space-charge effects on the oxygen-ionic transport in LSGO is given in [13]. Attention should also be paid to the origin of the grain-boundary resistance in highly doped LaGaO3, materials that are more relevant to practical applications. In highly doped samples, the influence of space-charge effects on grain-boundary conduction may be less, since the width of the space-charge zone (related to the Debye length) decreases with increasing dopant concentration in the bulk. This issue is currently under investigation.

Experimental

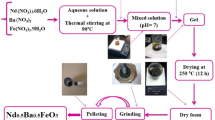

One mol% Sr-doped LaGaO3 (La0.99Sr0.01GaO3−x : LSGO) was synthesized employing a Pechini-type method using La(NO3)3 · 6H2O (99.9%, Sigma–Aldrich, St. Louis, MO, USA), Ga(NO3)3 · 8H2O (>99.9%, Sigma–Aldrich) and Sr(NO3)2 (99.9%, Sigma–Aldrich) as reactants. The synthesized LSGO was pressed into pellets at 300 MPa by cold isostatic pressing. The as-pressed pellets were sintered at 1600 °C for 10 h in air. The relative density of the sintered pellets, estimated using an Archimedean method, was above 95%. The chemical composition as well as the concentrations of background impurities (including Ca and Si) in the pellets were determined using inductively coupled plasma emission spectroscopy (ICP). The structure and phase homogeneity of the LSGO pellets was characterized using an X-ray diffractometer (XRD) with Cu-Kα radiation (XDS 2000, Scintag, Santa Clara, CA, USA). No indication of secondary phase formation was observed.

The microstructure of the pellets was examined using a high-resolution transmission electron microscope (HR-TEM, JEM-2500SE, JEOL, Tokyo, Japan).

The electrical resistance of the pellet was measured as a function of temperature (T = 250~600 °C) under different oxygen partial pressures using both two-probe ac impedance spectroscopy and a dc-measurement technique. Prior to the measurements, Pt electrodes were fabricated by painting Pt paste (5349, Heraeus, Hanau, Germany) on both surfaces of the pellet, followed by annealing at 1000 °C/1 h in air. Impedance spectra were obtained in the frequency range from 50 mHz to 10 MHz using an impedance analyzer (Novocontrol, Novocontrol Technology, Hundsangen, Germany). The total dc currents were measured using a source-measure unit (236, Keithley, Cleveland, OH, USA) in the high-temperature (≥750 °C) and the low-temperature (≤500 °C) regions. To minimize the electrode resistance of the pellet, which may be present at low temperatures, the surfaces of the pellets were coated with a porous composite layer. The composite material was prepared by mechanically mixing LSG and LSM (La0.8Sr0.2MnO3-δ, FCM, USA) powders (1:1 wt%) with the organic solvent. The slurry was screen-printed on the surface of the pellet and then heated at 1000 °C for 2 h in air.

The partial electronic current in the sample was measured using a dc-polarization method. A dc source meter (230, Keithley) was used to apply constant voltage (U) from 0 V to 1.0 V, and an electrometer (617, Keithley) was used to measure the current (I).

References

Maier J (2000) Point-defect thermodynamics and size effects. Solid State Ionics 131:13

Goodenough JB (2003) Oxide-ion electrolytes. Ann Rev Mat Res 33:91

Minh NQ (1993) Ceramic fuel-cells. J Am Ceram Soc 76(3):563

Steele BCH (2000) Materials for IT-SOFC stacks 35 years R&D: the inevitability of gradualness? Solid State Ionics 134(1–2):3

Guo X, Maier J (2001) Grain boundary blocking effect in zirconia: a Schottky barrier analysis. J Electrochem Soc 148(3):E121

Lee JS, Anselmi-Tamburini U, Munir ZA, Kim S (2006) A direct evidence of electron accumulation in the grain boundary of yttria doped nanocrystalline zirconia ceramics. Electrochem Solid-State Lett L9(8):J34

Kim S, Maier J (2002) On the conductivity mechanism of nanocrystalline ceria. J Electrochem Soc 149:J73

Tschoepe A (2001) Grain size-dependent electrical conductivity of polycrystalline cerium oxide II: space charge model. Solid State Ionics 139:267

Guo X, Waser R (2006) Electrical properties of the grain boundaries of oxygen ion conductors: acceptor-doped zirconia and ceria. Prog Mater Sci 51:152

Maier J (1995) Ionic conduction in space charge regions. Prog Solid State Chem 23:171

Kim S, Fleig J, Maier J (2003) Space charge conduction: simple analytical solutions for ionic and mixed conductors and application to nanocrystalline ceria. Phys Chem Chem Phys 5:2268

Ishihara T, Matsuda H, Takita Y (1994) Doped LaGaO3 perovskite-type oxide as a new oxide ionic conductor. J Am Chem Soc 116(9):3801

Park HJ, Kim S (2007) Space charge effects on the interfacial conduction in Sr-doped lanthanum gallates: a quantitative analysis. J Phys Chem C 111:14903

Park HJ, Kim S (2008) The enhanced electronic transference number at the grain boundaries in Sr-doped LaGaO3. Solid State Ionics 179:1329

Slater PR, Irvine JTS, Ishihara T, Takita Y (1998) The structure of the oxide ion conductor La0.9Sr0.1Ga0.8Mg0.2O2.85 by powder neutron diffraction. Solid State Ionics 107:319

Hebb MH (1952) Electrical conductivity of silver sulfide. J Chem Phys 20:185

Wagner C (1955) Galvanische Zellen mit festen Elektrolyten mit gemischter Stromleitung. Z Elektrochem 60:4

Volmamm M, Waser R (1994) Grain-boundary defect chemistry of acceptor-doped titanates—space-charge layer width. J Am Ceram Soc 77:235

Waser R (1995) Electronic-properties of grain-boundaries in SrTiO3 and BaTiO3 ceramics. Solid State Ionics 75:89

Waser R, Hagenbeck R (2000) Grain boundaries in dielectric and mixed conducting ceramics. Acta Mater 48:797

Denk I, Claus J, Maier J (1997) Electrochemical investigations of SrTiO3 boundaries. J Electrochem Soc 144:3526

Leonhardt M, Jamnik J, Maier J (1999) In situ monitoring and quantitative analysis of oxygen diffusion through Schottky-barriers in SrTiO3 bicrystals. Electrochem Solid-State Lett 2:333

De Souza RA, Zehnpfenning J, Martin M, Maier J (2005) Determining oxygen isotope profiles in oxides with Time-of-Flight SIMS. Solid State Ionics 176:1465

Acknowledgments

S. Kim is grateful to Dr. H. J. Park for discussion.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Kim, S. The intrinsic origin of the grain-boundary resistance in Sr-doped LaGaO3 . Monatsh Chem 140, 1053–1057 (2009). https://doi.org/10.1007/s00706-009-0136-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-009-0136-4