Abstract

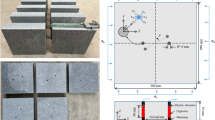

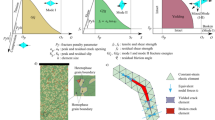

In this paper, the micro-cracking behaviour of pre-cracked Barre granite is investigated using a grain-based distinct element model (GBM). We investigated and demonstrated a cohesive model in a distinct element code, PFC2D, to mimic the elastic and softening response of the intra-grain contacts in the GBM. The study employed the smooth-joint model to simulate the micro-cracking behaviour of grain interfaces. The grain size distribution, as well as the mineral constituent of Barre granite, was incorporated in the numerical model. The model was calibrated against uniaxial compressive strength and Brazilian split-tensile-strength tests. We found that the GBM framework successfully reproduced the macroscopic physical properties obtained from the laboratory tests. When calibration was complete, the geometries of pre-existing cracks, which were considered in the experimental testing, were imported into the numerical model and used to generate synthetic, pre-cracked Barre granite. The macroscopic cracking process in the generated numerical models was observed by monitoring the evolution of intra- and inter-granular micro-cracks. The cracking and coalescence behaviour of numerical pre-cracked granite revealed that the proposed GBM approach can replicate the macroscopic fracturing pattern of pre-cracked Barre granite with close agreement to the experimental observations. The crack initiation, coalescence, and peak axial stresses were also recorded during numerical testings, and a good agreement was also achieved between these simulated results and the laboratory data. The proposed GBM framework is promising for research into micro-cracking behaviour of pre-cracked crystalline rocks under compressive loading.

modified from Morgan et al. (2013)

Similar content being viewed by others

References

Bahrani N, Kaiser PK (2016) Numerical investigation of the influence of specimen size on the unconfined strength of defected rocks. Comput Geotech 77:56–67. https://doi.org/10.1016/j.compgeo.2016.04.004

Bahrani N, Valley B, Kaiser PK, Pierce M (2011) Evaluation of PFC2D grain-based model for simulation of confinement-dependent rock strength degradation and failure processes. Paper presented at the 45th US Rock Mechanics/Geomechanics Symposium, San Francisco, California

Bahrani N, Kaiser PK, Valley B (2014) Distinct element method simulation of an analogue for a highly interlocked, non-persistently jointed rockmass. Int J Rock Mech Min Sci 71:117–130. https://doi.org/10.1016/j.ijrmms.2014.07.005

Bewick RP, Kaiser PK, Bawden WF (2014a) DEM Simulation of Direct Shear: 2. Grain Boundary and Mineral Grain Strength Component Influence on Shear Rupture. Rock Mech Rock Eng 47:1673–1692. https://doi.org/10.1007/s00603-013-0494-4

Bewick RP, Kaiser PK, Bawden WF, Bahrani N (2014b) DEM Simulation of Direct Shear: 1. Rupture Under Constant Normal Stress Boundary Conditions. Rock Mech Rock Eng 47:1647–1671. https://doi.org/10.1007/s00603-013-0490-8

Bobet A, Einstein HH (1998) Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min Sci 35:863–888. https://doi.org/10.1016/S0148-9062(98)00005-9

Brace WF, Bombolakis EG (1963) A note on brittle crack growth in compression. J Geophys Res 68:3709–3713. https://doi.org/10.1029/jz068i012p03709

Brace WF, Paulding BW, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71:3939–3953. https://doi.org/10.1029/jz071i016p03939

Brady BHG, Brown ET (2004) Rock Mechanics for Underground Mining, 3rd edn. Kluwer Academic Publishers, Netherlands

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44:997–1010. https://doi.org/10.1016/j.ijrmms.2007.02.002

Diaz MB, Jung SG, Zhuang L, Kim KY, Yeom S, Shin HS (2016) Effect of cleavage anisotropy on hydraulic fracturing behavior of pocheon granite. Paper presented at the 50th US. Rock Mechanics/Geomechanics Symposium, Houston, Texas

Farahmand K, Vazaios I, Diederichs MS, Vlachopoulos N (2018) Investigating the scale-dependency of the geometrical and mechanical properties of a moderately jointed rock using a synthetic rock mass (SRM) approach. Comput Geotech 95:162–179. https://doi.org/10.1016/j.compgeo.2017.10.002

Gao F, Stead D, Elmo D (2016) Numerical simulation of microstructure of brittle rock using a grain-breakable distinct element grain-based model. Comput Geotech 78:203–217. https://doi.org/10.1016/j.compgeo.2016.05.019

Hajiabdolmajid V, Kaiser PK, Martin CD (2002) Modelling brittle failure of rock. Int J Rock Mech Min Sci 39:731–741. https://doi.org/10.1016/S1365-1609(02)00051-5

Hoek E, Diederichs MS (2006) Empirical estimation of rock mass modulus. Int J Rock Mech Min Sci 43:203–215. https://doi.org/10.1016/j.ijrmms.2005.06.005

Hofmann H, Babadagli T, Yoon JS, Zang A, Zimmermann G (2015a) A grain based modeling study of mineralogical factors affecting strength, elastic behavior and micro fracture development during compression tests in granites. Eng Fract Mech 147:261–275. https://doi.org/10.1016/j.engfracmech.2015.09.008

Hofmann H, Babadagli T, Zimmermann G (2015b) A grain based modeling study of fracture branching during compression tests in granites. Int J Rock Mech Min Sci 77:152–162. https://doi.org/10.1016/j.ijrmms.2015.04.008

Horii H, Nemat-Nasser S (1985) Compression-induced microcrack growth in brittle solids: axial splitting and shear failure. J Geophys Res Solid Earth 90:3105–3125. https://doi.org/10.1029/jb090ib04p03105

Itasca Consulting Group Inc (2016) PFC manual, version 5.0, Minneapolis

Kazerani T, Zhao J (2010) Micromechanical parameters in bonded particle method for modelling of brittle material failure. Int J Numer Anal Method Geomech 34:1877–1895. https://doi.org/10.1002/nag.884

Kazerani T, Yang ZY, Zhao J (2012) A discrete element model for predicting shear strength and degradation of rock joint by using compressive and tensile test data. Rock Mech Rock Eng 45:695–709. https://doi.org/10.1007/s00603-011-0153-6

Khazaei C, Hazzard J, Chalaturnyk R (2015) Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput Geotech 67:94–102. https://doi.org/10.1016/j.compgeo.2015.02.012

Le LA, Nguyen GD, Bui HH, Sheikh AH, Kotousov A, Khanna A (2017) Modelling jointed rock mass as a continuum with an embedded cohesive-frictional model. Eng Geol 228:107–120. https://doi.org/10.1016/j.enggeo.2017.07.011

Le LA, Nguyen GD, Bui HH, Sheikh AH, Kotousov A, Khanna A (2018) Localised failure mechanism as the basis for constitutive modelling of geomaterials. Int J Eng Sci 133:284–310

Li Y-P, Chen L-Z, Wang Y-H (2005) Experimental research on pre-cracked marble under compression. Int J Solids Struct 42:2505–2516. https://doi.org/10.1016/j.ijsolstr.2004.09.033

Li XF, Zhang QB, Li HB, Zhao J (2018) Grain-based discrete element method (gb-dem) modelling of multi-scale fracturing in rocks under dynamic loading. Rock Mech Rock Eng 51:3785–3817. https://doi.org/10.1007/s00603-018-1566-2

Liu G, Cai M, Huang M (2018) Mechanical properties of brittle rock governed by micro-geometric heterogeneity. Comput Geotech. https://doi.org/10.1016/j.compgeo.2017.11.013

Ma Y, Huang H (2018a) DEM analysis of failure mechanisms in the intact Brazilian test. Int J Rock Mech Min Sci 102:109–119. https://doi.org/10.1016/j.ijrmms.2017.11.010

Ma Y, Huang H (2018b) A displacement-softening contact model for discrete element modeling of quasi-brittle materials. Int J Rock Mech Min Sci 104:9–19. https://doi.org/10.1016/j.ijrmms.2018.02.007

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. University of Manitoba, Winnipeg

Mayer JM, Stead D (2017) Exploration into the causes of uncertainty in UDEC grain boundary models. Comput Geotech 82:110–123. https://doi.org/10.1016/j.compgeo.2016.10.003

Miller JT (2008) crack coalescence in granite. MSc Thesis, Massachusetts Institute of Technology

Miller JT, Einstein HH (2008) Crack Coalescence tests on granite. Paper presented at the 42nd US Rock Mechanics Symposium (USRMS), San Francisco, California

Moore DE, Lockner DA (1995) The role of microcracking in shear-fracture propagation in granite. J Struct Geol 17:95–114. https://doi.org/10.1016/0191-8141(94)E0018-T

Moradian Z, Einstein HH, Ballivy G (2016) Detection of cracking levels in brittle rocks by parametric analysis of the acoustic emission signals. Rock Mech Rock Eng 49:785–800. https://doi.org/10.1007/s00603-015-0775-1

Morgan SP, Johnson CA, Einstein HH (2013) Cracking processes in Barre granite: fracture process zones and crack coalescence. Int J Fract 180:177–204. https://doi.org/10.1007/s10704-013-9810-y

Mosher S, Berger RL, Anderson DE (1975) Fracturing characteristics of two granites. Rock Mech 7:167–176. https://doi.org/10.1007/bf01246723

Munoz H, Taheri A, Chanda EK (2016) Pre-peak and post-peak rock strain characteristics during uniaxial compression by 3D digital image correlation. Rock Mech Rock Eng 49:2541–2554. https://doi.org/10.1007/s00603-016-0935-y

Nguyen NHT, Bui HH, Nguyen GD, Kodikara J (2017a) A cohesive damage-plasticity model for DEM and its application for numerical investigation of soft rock fracture properties. Int J Plast 98:175–196. https://doi.org/10.1016/j.ijplas.2017.07.008

Nguyen NHT, Bui HH, Nguyen GD, Kodikara J, Arooran S, Jitsangiam P (2017b) A thermodynamics-based cohesive model for discrete element modelling of fracture in cemented materials. Int J Solids Struct 117:159–176. https://doi.org/10.1016/j.ijsolstr.2017.03.027

Nicksiar M, Martin CD (2014) Factors affecting crack initiation in low porosity crystalline rocks. Rock Mech Rock Eng 47:1165–1181. https://doi.org/10.1007/s00603-013-0451-2

Peng J, Wong LNY, Teh CI (2017) Effects of grain size-to-particle size ratio on micro-cracking behavior using a bonded-particle grain-based model. Int J Rock Mech Min Sci 100:207–217. https://doi.org/10.1016/j.ijrmms.2017.10.004

Potyondy D (2010a) A grain-based model for rock: approaching the true microstructure. In: Proceedings Rock Mechanics in the Nordic Countries,2010

Potyondy D (2010b) PFC2D Grain-Structure Generator. PFC2D Example on Itasca website. Itasca Consulting Group, Inc, Minneapolis

Potyondy D (2012) A flat-jointed bonded-particle material for hard rock. Paper presented at the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, Illinois

Potyondy D, Cundall P (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Pouya A, Yazdi P (2015) A damage-plasticity model for cohesive fractures. Int J Rock Mech Min Sci 73:194–202

Cao R-H, Cao P, Lin H, Pu C-z OuK (2016) Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: experimental studies and particle mechanics approach. Rock Mech Rock Eng 49:763–783. https://doi.org/10.1007/s00603-015-0779-x

Rodríguez P, Arab PB, Celestino TB (2016) Characterization of rock cracking patterns in diametral compression tests by acoustic emission and petrographic analysis. Int J Rock Mech Min Sci 83:73–85. https://doi.org/10.1016/j.ijrmms.2015.12.017

Saadat M, Taheri A (2019) A numerical approach to investigate the effects of rock texture on the damage and crack propagation of a pre-cracked granite. Comput Geotech 111:89–111. https://doi.org/10.1016/j.compgeo.2019.03.009

Shen B, Stephansson O, Einstein Herbert H, Ghahreman B (1995) Coalescence of fractures under shear stresses in experiments. J Geophys Res Solid Earth 100:5975–5990. https://doi.org/10.1029/95jb00040

Taheri A, Tani K (2008) Developing of an apparatus for down-hole triaxial tests in a rock mass. Int J Rock Mech Min Sci 45:800–806

Taheri A, Tani K (2010) Assessment of the stability of rock slopes by the slope stability rating classification system. Rock Mech Rock Eng 43:321–333. https://doi.org/10.1007/s00603-009-0050-4

Taheri A, Yfantidis N, Olivares C, Connelly B, Bastian T (2016) Experimental study on degradation of mechanical properties of sandstone under different cyclic loadings. Geotech Test J 39:673–687. https://doi.org/10.1520/gtj20150231

Tang CA, Liu H, Lee PKK, Tsui Y, Tham LG (2000) Numerical studies of the influence of microstructure on rock failure in uniaxial compression—Part I: effect of heterogeneity. Int J Rock Mech Min Sci 37:555–569. https://doi.org/10.1016/S1365-1609(99)00121-5

Tavallali A, Vervoort A (2010) Failure of layered sandstone under Brazilian test conditions: effect of micro-scale parameters on macro-scale behaviour. Rock Mech Rock Eng 43:641–653. https://doi.org/10.1007/s00603-010-0084-7

Tuğrul A, Zarif IH (1999) Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Eng Geol 51:303–317. https://doi.org/10.1016/S0013-7952(98)00071-4

Ulusay R (2015) The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. Springer, Berlin, pp 47–48

Wong RHC, Chau KT (1998) Crack coalescence in a rock-like material containing two cracks. Int J Rock Mech Min Sci 35:147–164. https://doi.org/10.1016/S0148-9062(97)00303-3

Wong LNY, Einstein HH (2009) Crack coalescence in molded gypsum and Carrara marble: part 1 macroscopic observations and interpretation. Rock Mech Rock Eng 42:475–511. https://doi.org/10.1007/s00603-008-0002-4

Wu XY, Baud P, T-f Wong (2000) Micromechanics of compressive failure and spatial evolution of anisotropic damage in Darley Dale sandstone. Int J Rock Mech Min Sci 37:143–160. https://doi.org/10.1016/S1365-1609(99)00093-3

Yin P, Wong RHC, Chau KT (2014) Coalescence of two parallel pre-existing surface cracks in granite. Int J Rock Mech Min Sci 68:66–84. https://doi.org/10.1016/j.ijrmms.2014.02.011

Yoon JS, Zang A, Stephansson O (2012) Simulating fracture and friction of Aue granite under confined asymmetric compressive test using clumped particle model. Int J Rock Mech Min Sci 49:68–83. https://doi.org/10.1016/j.ijrmms.2011.11.004

Zeng W, Yang S-Q, Tian W-L (2018) Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng Fract Mech 200:430–450. https://doi.org/10.1016/j.engfracmech.2018.08.016

Zhang X-P, Wong LNY (2012) Cracking processes in rock-like material containing a single flaw under uniaxial compression: a numerical study based on parallel bonded-particle model approach. Rock Mech Rock Eng 45:711–737. https://doi.org/10.1007/s00603-011-0176-z

Zhang X-P, Wong LNY (2013) Crack initiation, propagation and coalescence in rock-like material containing two flaws: a numerical study based on bonded-particle model approach. Rock Mech Rock Eng 46:1001–1021. https://doi.org/10.1007/s00603-012-0323-1

Zhang Y, Wong LNY (2018) A review of numerical techniques approaching microstructures of crystalline rocks. Comput Geosci 115:167–187. https://doi.org/10.1016/j.cageo.2018.03.012

Zhao C, Ym Zhou, Cf Zhao, Bao C (2018) Cracking processes and coalescence modes in rock-like specimens with two parallel pre-existing cracks. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-018-1525-y

Zhou XP, Cheng H, Feng YF (2014) An experimental study of crack coalescence behaviour in rock-like materials containing multiple flaws under uniaxial compression. Rock Mech Rock Eng 47:1961–1986. https://doi.org/10.1007/s00603-013-0511-7

Zhou X-P, Zhang J-Z, Wong LNY (2018) Experimental study on the growth, coalescence and wrapping behaviors of 3D cross-embedded flaws under uniaxial compression. Rock Mech Rock Eng 51:1379–1400. https://doi.org/10.1007/s00603-018-1406-4

Acknowledgements

The cohesive model used in this study was formulated based on a generic framework by Giang D. Nguyen (University of Adelaide) and Ha H. Bui (Monash University), with Giang D. Nguyen’s help in the development and revision of the model. The first author is grateful to Mr Sacha Emam from Itasca Consulting group who provided consultation during implementation and verification of the model in PFC2D software. Professional editor, Leticia Mooney, provided copyediting and proofreading services, according to the guidelines laid out in the university-endorsed national ‘Guidelines for editing research theses’.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The first author declares that he has no conflict of interest. The second author declares that he has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saadat, M., Taheri, A. Modelling Micro-cracking Behaviour of Pre-cracked Granite Using Grain-Based Distinct Element Model. Rock Mech Rock Eng 52, 4669–4692 (2019). https://doi.org/10.1007/s00603-019-01862-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-01862-0