Abstract

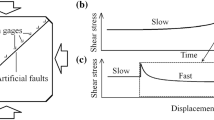

The influence of mineral grain and grain boundary strength is investigated using a calibrated intact (non-jointed) brittle rock specimen subjected to direct shear with a particle-based distinct element method and its embedded grain-based method. The adopted numerical approach allows one to independently control the grain boundary and mineral grain strength. The investigation reveals that, in direct shear, the normal stress (σ n) applied to a rock specimen relative to its uniaxial compressive strength (UCS) determines the resulting rupture mechanism, the ultimate rupture zone geometry, and thus its shear stress versus horizontal displacement response. This allows one to develop a rupture matrix based on this controlling parameter (i.e., σ n/UCS). Mineral grain strength reductions result in the lowering of the apparent cohesion intercept of the peak linear Coulomb strength envelope, while grain boundary strength reductions change the peak linear Coulomb strength envelope to a bi-linear or curved shape. The impact of grain boundary strength is only relevant at σ n/UCS ratios <0.17 where tensile and dilatant rupture mechanisms dominate. Once shear rupture begins to be the dominant rupture mechanism in a brittle rock (i.e., at σ n/UCS ratios >0.17), the influence of weakened grain boundaries is minimized and strength is controlled by that of the mineral grains.

Similar content being viewed by others

References

Bewick RP, Valley B, Kaiser PK (2012) Effect of grain scale geometric heterogeneity on tensile stress generation in rock loaded in compression. In: 46th US Rock Mechanics/Geomechanics Symposium. Chicago, June 24–27

Bewick RP, Kaiser PK, Bawden WF (2013) DEM simulation of direct shear: 1. Constant normal stress boundary conditions. Rock Mech Rock Eng. doi:10.1007/s00603-013-0490-8

Cresswell AW, Barton ME (2003) Direct shear tests on an uncemented, and a very slightly cemented, locked sand. Q J Eng Geol Hydrogeol 36:119–132

Deere DU (1968) Geological considerations. In: Stagg KG, Zienkiewicz OC (eds) Rock mechanics in engineering practice. Wiley, London

Dusseault MB, Morgenstern NR (1978) Shear strength of Athabasca Oil Sands. Can Geotech J 15:216–238

Hoek E (1968) Brittle fracture of rock. In: Stagg KG, Zienkiewicz OC (eds) Rock mechanics in engineering practice. Wiley, London

Itasca Consulting Group (2011) Particle flow code in two dimensions, vol 4.00–190. Minneapolis, MN, USA

Lajtai EZ (1969) Mechanics of second order faults and tension gashes. Geol Soc Am Bull 80:2253–2272

Lan H, Martin DC, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behaviour during compression loading. J Geophys Res 115:B01202. doi:10.1029/2009JB006496

Martin CD, Kaiser PK, Christiansson R (2003) Stress, instability and design of underground excavations. Int J Rock Mech Min Sci 40:1027–1047

Patton F (1966) Multiple modes of shear failure in rock. First Congress of the International Society of Rock Mechanics. Lisbon 1:509–513

Petit J-P (1988) Normal stress dependent rupture morphology in direct shear tests on sandstone with applications to some natural fault surface features. Int J Rock Mech Min Sci Geomech Abstr 25:411–419

Potyondy DO (2010) A grain-based model for rock: approaching the true microstructure. In: Li CC et al (eds) Proceedings, Bergmekanikk i Norden 2010—Rock Mechanics in the Nordic Countries 2010 (Kongsberg, Norway, June 2010), Norwegian Group for Rock Mechanics, Oslo, pp 225–234

Rosengren KJ, Jaeger JC (1968) The mechanical properties of an interlocked low-porosity aggregate. Geotechnique 18:317–326

Wibberley CAJ, Petit JP, Rives T (2000) Micromechanics of shear rupture and the control of normal stress. J Struct Geol 22:411–427

Acknowledgments

This research was supported by the Centre for Excellence in Mining Innovation (CEMI) and the Natural Sciences and Engineering Research Council of Canada (NSERC). Constructive and helpful comments by the reviewers, which improved the manuscript, are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bewick, R.P., Kaiser, P.K. & Bawden, W.F. DEM Simulation of Direct Shear: 2. Grain Boundary and Mineral Grain Strength Component Influence on Shear Rupture. Rock Mech Rock Eng 47, 1673–1692 (2014). https://doi.org/10.1007/s00603-013-0494-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-013-0494-4