Abstract

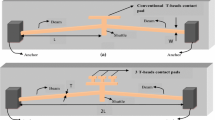

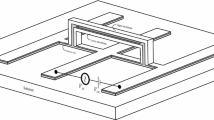

Fabrication and characterization of a novel bistable MEMS (MicroElectroMechanical Systems)-based switch is reported in this paper. The bistable switch is fabricated on SOI wafer with 10 µm thick device Si layer using Silicon-On-Insulator Multi User MEMS Process with three masks. The proposed device is comprised of a centrally clamped parallel curved beams (switching element) and a pair of electrothermal V-beam microactuators (actuating element). The bistability is achieved through the buckling of centrally clamped parallel curved beams and the critical buckling load is provided by the electro-thermal expansion of the V-beam microactuators. Hinges, latches, membranes are not used in the proposed design and thus the fabrication complexity is reduced to a greater extent. A maximum displacement of 20.7 µm is achieved at 14 V DC supply for the V-beam microactuator and this thermal expansion of the V-beam microactuator acted as the critical buckling load for the centrally clamped parallel curved beam. Electrical and mechanical characterization of switch is performed and after the analysis, it is verified that the nonlinear property (elasticity) of silicon material is poor and that is the reason for comparatively higher actuation voltage to simulation results. A novel optimized redesign for the electrothermal V-beam microactuator based on POLYMUMPs process is proposed in order to overcome the uncertainties endured.

Similar content being viewed by others

References

Cazottes P, Fernandes A, Pouget J, Hafez M (2009) Bistable buckled beam: modeling of actuating force and experimental validations. J Mech Des 131:101001

Cheng WJ (2005) Design and fabrication of electrothermal micromotors and compliant mechanisms for spatial parallel micromanipulators. Ph.D. dissertation, pp 91–97

Chiorean RS (2015) Electro-thermo Mechanical Modeling of V-beam microactuators. Proc Technol 19:56–61

Chiorean RS, Dudescu MC, Pustan M, Hardau M (2014) Analytical and numerical study on the maximum force developed by a V-beam thermal microactuator. Proc Technol 12:359–363

Correa DM, Seepersad CC, Haberman MR (2015) Mechanical design of negative stiffness Honeycomb materials. Integr Mater Manuf Innov 4:1–11

Fuentes M, Weber E, Wilson S, Li B, Crozier S (2010) MEMS based RF switch in MRI—a performance study. Proc Int Soc Mag Reson Med (18)

Huang HW, Yang YJ (2013) A MEMS bistable device with push-on-push-off capability. J Microelectromech Syst 22(1):7–9

Joshitha C, Sreeja BS (2014) Design and analysis of bistable MEMS switch. IEEE conference-ICICES2014, ISBN No. 978-1-4799-3834-6/14

Kumar V, Sharma NN (2014) Design and validation of silicon-on-insulator based U shaped thermal microactuator. Int J Mater Mech Manuf 2(1):86–91

Lee C, Wu CY (2004) Study of electrothermal V-beam microactuators and latched mechanism for optical switch. J Micromech Microeng 15:11–19

Park S (2009) A study on buckled-beam microactuators for RF MEMS applications, Ph.D. dissertation, pp 12–18

Pirmoradi E, Mirzajani H, Ghavifekr HB (2015) Design and simulation of a novel electro-thermally actuated lateral RF MEMS latching switch for low power applications. Microsyst Technol 21(2):465–475

Qiu J, Lang JH, Slocum AH (2004) A curved beam bistable mechanism. J Microelectromech Syst 13(2):137146

Qiu J, Lang JH, Slocum AH (2005) A bulk micromachined bistable relay with U-shaped thermal microactuators. J Microelectromech Syst 14(5):10991109

Receveur RAM, Marxer CR, Woering R, Larik VCMH, de Rooji NF (2005) Laterally moving bistable DC switch for biomedical applications. J Microelectromech Syst 14(5):1089–1098

Zhang Z, Yu Y, Liu X, Zhang X (2015) A comparison model of V- and Z-shaped electrothermal microactuators. In: Proceedings of 2015 IEEE International Conference on Mechatronics and Automation

Zhu Y, Moheimani SOR, Yuce MR (2012) Bidirectional electrothermal microactuator with Z-shaped beams. IEEE Sens J 12(7):2508–2509

Acknowledgements

The authors acknowledge that part of the reported work (fabrication/characterization) was carried out at CeNSE, IISc, Bangalore under Indian Nano User Program (INUP) which have been sponsored by DIT and MCIT, Government of India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is not any conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Joshitha, C., Sreeja, B.S., Sasi Princy, S. et al. Fabrication and investigation of low actuation voltage curved beam bistable MEMS switch. Microsyst Technol 23, 4553–4566 (2017). https://doi.org/10.1007/s00542-016-3235-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-3235-2