Abstract

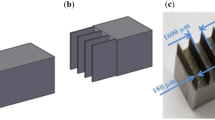

Microfluidic channels have been created for quartz material using micromechanical manufacturing technologies such as micro laser machining, micro ultrasonic machining, and ultra-precision machining. Ultra-precision machining has been used to manufacture cross-junction channels 14 µm wide and 28 µm deep with a three-dimensional triangle cross-section. Micro laser machining has been used

to manufacture U-shaped and  -shaped microfluidic channels. Deep holes and microfluidic channels with a high slenderness ratio (width/depth) can be obtained by using micro ultrasonic machining technology. These three machining techniques are compared with respect to surface profiles and machining quality.

-shaped microfluidic channels. Deep holes and microfluidic channels with a high slenderness ratio (width/depth) can be obtained by using micro ultrasonic machining technology. These three machining techniques are compared with respect to surface profiles and machining quality.

Similar content being viewed by others

References

Anderson DG, Xu QB, Hashimoto M, Whitesides GM, Langer R (2009) Preparation of monodisperse biodegradable polymer microparticles using a microfluidic flow-focusing device for controlled drug delivery. Small 5:1575–1581

Bhuyan MK, Courvoisier F, Lacourt PA, Jacquot M, Furfaro L, Withford MJ, Dudley JM (2010) High aspect ratio taper-free microchannel fabrication using femtose-cond Bessel beams. Opt Express 18:566–574

Bokenkamp D, Desai A, Yang X, Tai YC, Marzluff E, Mayo S (1998) Microfabricated silicon mixers for submillisecond quench-flow analysis. Anal Chem 70:232–236

Borghi A, Gualtieri E, Marchetto D, Moretti L, Valeri S (2008) Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 2651046-2651051

Brivio M, Verboom W, Reinhoudt DN (2006) Miniaturized continuous flow reaction vessels: influence on chemical reactions. Lab Chip 6:329–344

Chu LY, Utada AS, Shah RK, Kim JW, Weitz DA (2007) Controllable monodisperse multiple emulsions. Angew Chem Int Ed 46:8970–89744

Dittrich PS, Manz A (2006) Lab-on-a-chip: microfluidics in drug discovery. Rev Drug Discov 5:211–218

Gattass RR, Mazur E (2008) Femtosecond laser micromachining in transparent materials. Nat Photon 2:219–225

Hettiarachchi K, Talu E, Longo ML, Dayton PA, Lee AP (2007) On-chip generation of microbubbles as a practical technology for manufacturing contrast agents for ultrasonic imaging. Lab Chip 7:463–468

Hisamoto H, Saito T, Tokeshi M, Hibara A, Kitamori T (2001) Fast and high conversion phase-transfer synthesis exploiting the liquid–liquid interface. Chem Commun 24:2662–2663

Kalek C, Robert L, Boy JJ, Blind P (2007) Deep microstructuring in glass for microfluidic applications. Microsyst Technol 13:447–453

Leng XF, Zhang WH, Wang CM, Cui L, Yang CY (2010) Agarose droplet microfluidics for highly parallel and efficient single molecule emulsion PCR. Lab Chip 10:2841–2843

Liu C, Liao Y, He F, Shen Y, Chen D, Cheng Y, Xu Z, Sugioka K, Midorkawa K (2012) Fabrication of three-dimensional microfluidic channels inside glass using nanosecond laser direct writing. Opt Express 20:4291–4296

Menezes PL, Kailas, Kishore SV, Lovell MR (2010) Response of materials during sliding on various surface textures. J Mater Eng Perform 20:1438–1449

Mitchell MC, Spikmans V, de Mello AJ (2001) Microchip-based synthesis and analysis: control of multicomponent reaction products and intermediates. Analyst 126:24–27

Nakano M, Korenaga A, Korenaga A, Miyake K, Murakami T, Ando Y, Usami H, Sasaki S (2007) Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions. Tribol Lett 28:131–137

Queste S, Salut R, Clatot S, Rauch JY, Malek CGK (2010) Manufacture of microfluidic glass chips by deep plasma etching, femtosecond laser ablation, and anodic bonding. Microsyst Technol 16:1485–1493

Stroock AD, Dertinger SKW, Ajdari A, Mezi’ C, Stone I, Whitesides GM (2002) Chaotic mixer for microchannel. Science 295:647–651

Utada AS, Lorenceau E, Link DR, Kaplan PD, Stone HA, Weitz DA (2005) Monodisperse double emulsions generated from a microcapillary device. Science 308:537–541

Yang Z, Matsumoto S, Goto H, Matsumoto M, Maeda R (2001) Ultrasonic micromixer for microfluidic systems sensor. Actuat A-Phys 93:266–272

Zhang J, Midorikawa K (1999) High-quality and high-efficiency machining of glass materials by laser-induced plasma-assisted ablation using conventional nanosecond UV, visible, and infrared lasers Appl. Phys A 69:S879–S882

Zhang J, Sugioka K, Midorikawa K (1998) High-speed machining of glass materials by laser-induced plasma-assisted ablation using a 532-nm laser. Appl Phys A 67:499–501

Zhang B, Tice JD, Ismagilov RF (2004) Formation of droplets of in microfluidic channels alternating composition and applications to indexing of concentrations in droplet-based. Anal Chem 76:4977–49782

Zhang H, Tumarkin E, Peerani R, Nie Z, Sullan RM, Walker GC, Kumacheva E (2006) Microfluidic production of biopolymer microcapsules with controlled morphology. J Am Chem Soc 128:12205–12210

Zheng HY, Lee T (2005) Studies of CO2 laser peeling of glass substrates. J Micromech Microeng 15:2093–2097

Acknowledgments

The support from the Ministry of Economic Affairs and Micro/Meso Mechanical Manufacturing R&D Department, Taiwan, through Grants A0245010 and A0245020 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, YC., Lee, CC., Lin, HS. et al. Fabrication of microfluidic structures in quartz via micro machining technologies. Microsyst Technol 23, 1661–1669 (2017). https://doi.org/10.1007/s00542-015-2717-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2717-y