Abstract

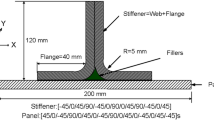

Flexible touch panel is required to undertake extensive bending operations during service; thus, bending testing of flexible touch panel for mechanical behaviors and even reliability is crucial for realizing the technology. This study aims at exploring the bending behaviors of a flexible touch panel under a four-point bending test using finite element analysis. The touch panel is a laminated structure composed of seven thin film layers, namely a polyester layer, an adhesive layer, a polyimide layer, two organic layers and two indium tin oxide conductive layers. Because the touch panel structure is symmetry, only a quarter of the flexible touch panel is established in the analysis model. The mechanical properties of the materials are first obtained using both nanoindentation and uniaxial tensile/compressive testing. Furthermore, a modeling technique based on global and local finite element analysis is applied to evaluate the bending stress at a specified radius of curvature. Special emphasis of the calculation is put on the critical region with respect to stress, which is identified as the most susceptible cracking site.

Similar content being viewed by others

References

Alzoubi K, Hamasha MM, Lu S, Sammakia BS (2010) Bending fatigue study of sputtered ITO on flexible substrate. J Disp Technol 7(11):593–600. doi:10.1109/JDT.2011.2151830

ANSYS Release 12.1 (2010) ANSYS, Inc., Canonsburg, PA, USA. http://www.ansys.com/

Caims DR, Paine DC, Carwford GP (2001) The mechanical reliability of sputter-coated indium tin oxide polyester substrates for flexible display and touchscreen applications. MRS Proc 666. doi:10.1557/PROC-666-F3.24

Chen Q, Xu L, Salo A (2008) Reliability study of flexible display module by experiments. ICEPT-HDP IEEE. doi:10.1109/ICEPT.2008.4607161

Crawford GP (2005) Flexible flat panel displays. Wiley, New York

Grego BS, Lewis J, Vick E, Temple D (2005) Development and evaluation of bend-testing techniques for flexible-display applications. J SID 13(7):575–581. doi:10.1889/1.2001215

Lan F, Peng WC, Lo YH, He JL (2010) Durability under mechanical bending of the indium tin oxide films deposited on polymer substrate by thermionically enhanced sputtering. Org Electron 11:670–676. doi:10.1016/j.orgel.2010.01.008

Lee SK, Lee JU (2003) The fracture distribution in ITO coating with compressive bending stress on polymer substrates. Trans Electr Electron Mater 4(6):5–8

Leterrier Y, Fischer C, Médico L, Demarco F, Månson JAE, Bouten P, Degoede J, Naim JA (2003) Mechanical properties of transparent functional thin films for flexible displays. In: Proceedings of the 46th annual technical conference

Li JP, Yang P, Zhong J (2009) Thermal analysis based on the environmental tests of STN display. EuroSimE IEEE Conf. doi:10.1109/ESIME.2009.4938420

Oh JS, Cho YR, Cheon KE, Karim MA, Jung SJ (2007) Failure mechanism of patterned ITO electrodes on flexible substrate under static and dynamic mechanical stresses. Solid State Phenom 124-126:411–414. doi:10.4028/www.scientific.net/SSP.124-126.411

Park SK, Han JI, Moon DG, Kim WK (2003) Mechanical stability of externally deformed indium–tin–oxide films on polymer substrates. Jpn Soc Appl Phys 42(2A):623–629. doi:10.1143/JJAP.442.623

Sierros A, Morris NJ, Ramji K, Carins DR (2009) Stress–corrosion cracking of indium tin oxide coated polyethylene terephthalate for flexible optoelectronic devices. Thin Solid Film 517:2590–2595. doi:10.1016/j.tsf.2005.10.031

Sim B, Kim EH, Park J, Lee M (2009) Highly enhanced mechanical stability of indium tin oxide film with a thin al buffer layer deposited on plastic substrate. Surf Coat Technol 204:309–312. doi:10.1016/j.surfcoat.2009.07.028

Yeh MK, Chang LY, Cheng HC, Wang PH (2013) Bending stress analysis of laminated foldable touch panel. In: Proceeding of the 37th National Conference on Theoretical and Applied Mechanics and The 1st International Conference on Mechanics, Hsinchu, Taiwan, Paper No. 97

Yu Z, Xiang L, Xue W, Wang H (2007) The bending properties of flexible ITO films. In: IEEE Optical Fiber Communication and Optoelectronics Conference, Asia, 17–19 October, Shanghai, pp. 148–150. doi: 10.1109/AOE.2007.4410733

Acknowledgments

This work was supported by the cooperative project between the Industrial Technology Research Institute and National Tsing Hua University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeh, MK., Chang, LY., Lu, MR. et al. Bending stress analysis of flexible touch panel. Microsyst Technol 20, 1641–1646 (2014). https://doi.org/10.1007/s00542-014-2200-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2200-1