Abstract

Micro-injection molding is the main method molding complex micro plastic parts accurately at one process. It is more complex than traditional injection molding because of the micro-scale effect. The polymeric flow in micro channels differs from those in macro ones significantly, and the molding theories of traditional injection molding can not be used in micro-injection molding. In this study, the effects of micro-scale, such as micro-viscosity and wall slip, were considered based on the flow characteristics of micro-injection molding, and the mathematical model and the numerical model were built. The simulation of filling stage in micro-injection molding was implemented by hybrid finite element/finite difference/control volume method accordingly. The influence of micro-viscosity and wall slip on filling stage was investigated by numerical analysis. The results indicated that the micro-scale effects have important influence on the filling stage of micro-injection molding, and the micro-scale effects become more and more significant as the gap thickness drops.

Similar content being viewed by others

References

Kim DS, Lee KC, Kwon TH, Lee SS (2003) Micro-channel filling flow considering surface tension effect. J Micromech Microeng 12:236–246

Pioter V, Mueller K, Plewa K, Ruprecht R, Hausselt J (2002) Performance and simulation of thermoplastic micro injection molding. Microsyst Technol 8:387–390

Rosebaun EE, Hatzikiriakos SG (1997) Wall slip in the capillary flow of molten polymers subject to viscous heating. AIChE J 43:598–608

Shen CY, Wang LX, Li Q (2007) Numerical simulation of compressible flow with phase change of filling stage in injection molding. J Reinf Plast Compos 26(4):353–372

Xu B, Ooi KT, Wong TN, Liu CY (1999) Study on the viscosity of the liquid flowing in microgeometry. J Micromech Microeng 9:337–384

Yao DG, Kim B (2002) Simulation of the filling process in micro channels for polymeric materials. J Micromech Microeng 12(5):604–610

Yong WB (2005) Simulation of the filling process in molding components with micro channels. Microsyst Technol 11:410–415

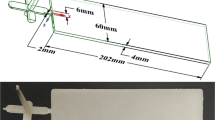

Zhu WN (2009) Numerical simulation of the filling stage of micro-injection molding in slit cavity. Master Thesis, Zhengzhou University

Acknowledgments

The authors would like to express their gratitude to the National Engineering Research Center for Advance Polymer Processing Technology and School of Mechanics and Engineering Science of Zhengzhou University in China, for the funding support of ‘Major Research Plan of Henan public projects (HNZB[2010]N91)’ and the special pre-research project of the 973 Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Li, Q., Zhu, W. et al. Scale effect on filling stage in micro-injection molding for thin slit cavities. Microsyst Technol 18, 2085–2091 (2012). https://doi.org/10.1007/s00542-012-1545-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1545-6