Abstract

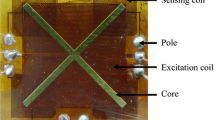

A rapid manufacturing process for the micro solenoid fluxgate sensor integrating multilayer amorphous ribbon core has been established, which combines the micro assembling method and the MEMS technologies. We select Fe-based amorphous soft magnetic ribbons for core materials and have fabricated the micro fluxgate sensors by MEMS technologies, with single-layer core and double-layer core respectively. The micro fluxgate sensors with double-layer core show the advantageous to that with single-layer core and exhibit sensitivity of 1089.2 V/T at excitation current of 120 mA rms, wide linear range of −900 to 900 μT and power consumption of 24.48 mW. The noise power density of the single core fluxgate sensor is 2.48nT/Hz1/2@1 Hz.

Similar content being viewed by others

References

Acuna MH (2002) Space-based magnetometers. Rev Sci Instrum 73:3717–3736

Baschirotto A, Dallago E, Malcovati P, Marchesi M, Melissano E, Morelli M, Siciliano P, Venchi G (2009) An integrated micro-fluxgate magnetic sensor with front-end circuitry. IEEE T Instrum Meas 58:3269–3275

Choi WY (2006) Two-axis micro fluxgate sensor on single chip. Microsyst Technol 12:352–356

Frydrych P, Szewczyk R, Salach J, Trzcinka K (2011) New two-axis fluxgate sensor. Prz Elektrotechniczn 87:53–55

Heim E, Harling S, Pohlig K, Ludwig F, Menzel H, Schilling M (2007) Fluxgate magnetorelaxometry of superparamagnetic nanoparticles for hydrogel characterization. J Magn Magn Mater 311:150–154

Kaluza F, Gruger A, Gruger H (2003) New and future applications of fluxgate sensors. In:4th European magnetic sensors and actuators conference EMSA 2002, Elsevier, Switzerland, p 48–51, 3–5 July 2002

Kirchhoff MR, Büttgenbach S (2010) MEMS fluxgate magnetometer for parallel robot application. Microsyst Technol 16:787–790

Kubik J, Pavel L, Ripka P, Kaspar P (2007) Low-power printed circuit board fluxgate sensor. IEEE Sens J 7:179–183

Lei C, Chen L, Lei J, Yang X, Zhou Y (2011) Ultra low power solenoid MEMS fluxgate sensor with amorphous alloy core. Sensor Lett V9:1689–1691

Liakopoulos TM, Ahn CH (1999) A micro-fluxgate magnetic sensor using micromachined planar solenoid coils. Sensor Actuat A Phys 77:66–72

Ludwig F, Heim E, Eberbeck D, Schwarz K, Trahms L, Schilling M (2009) Comparison and calibration of fluxgate and SQUID magnetorelaxometry techniques for the characterization of magnetic core-shell nanoparticles. IEEE T Magn 45:4857–4860

Ripka P (2008) Sensors based on bulk soft magnetic materials: Advances and challenges. J Magn Magn Mater 320:2466–2473

Robertson PA (2000) Microfabricated fluxgate sensors with low noise and wide bandwidth. Electron Lett 36:331–332

Velasco-Quesada G, Roman-Lumbreras M, Conesa-Roca A, Jerez F (2011) Design of a low-consumption fluxgate transducer for high-current measurement applications. IEEE Sens J 11:280–287

Zhang YM, Steiger M, Hibbs AD, Grimm RE, Sprott TA (2010) Dual-mode, fluxgate-induction sensor for UXO detection and discrimination. J Environ Eng Geophys 15:51–64

Zorlu O, Kejik P, Popovic RS (2007) An orthogonal fluxgate-type magnetic microsensor with electroplated Permalloy core. Sensor Actuat A Phys 135:43–49

Acknowledgments

This work was supported by Basic Research Program of Science and Technology Committee of Shanghai (09JC1408600), The National Natural Science Foundation of China (No. 61074168), and National Key Laboratory Research Fund (9140C790403110C7905).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lei, C., Lei, J., Yang, Z. et al. Improved micro fluxgate sensor with double-layer Fe-based amorphous core. Microsyst Technol 19, 167–172 (2013). https://doi.org/10.1007/s00542-012-1523-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1523-z