Abstract

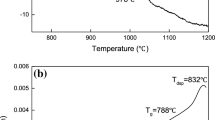

Surface treatment on glass before thermal assisted direct bonding (TADB) is an issue for lab-on chip fabrication. Surface cleaning for obtaining good quality TADB on soda-lime glass are studied and tested in this paper. The optimized cleaning solution for soda lime glass samples is NH4OH–H2O2–H2O (0.5:1:5 volume ratio) and it can be considered as the optimised solution for cleaning soda-lime glasses by this solution, as a result of a trade-off between cleaning efficiency and surface etching. The surface quality before and after cleaning is evaluated by optical microscopy, profilometry and atomic force microscopy. TADB between the cleaned samples is carried out and the bonding strength measured. The tensile strength of optimized samples after TADB was found to be higher than 15 MPa.

Similar content being viewed by others

References

Chen Q, Milanese D, Chen Q, Ferraris M et al (2005) Direct bonding and ion exchange for waveguide lossless splitter fabrication. ICG/ISG 2005, p5

Chen Q, Chen Q, Milanese D, Ferraris M, Fokine M (2007) Direct bonding and imprinting techniques for micro-fluidic devices fabri-cation in commercial soda-lime glass, Patent No. TO2007A000345

Chen Q, Milanese D, Chen Q, Ferraris M et al (2008) Fabrication and direct bonding of photosensitive multi-component silicate glasses for lossless planar waveguide splitter. J Non-Cryst Solids 354:1230–1234. doi:10.1016/j.jnoncrysol.2006.11.045

Chen Q, Chen Q, Milanese D, Ferraris M (2009) Micro-structures fabrication on glasses for micro-fluidics by imprinting technique. J Microsys Technol (in press)

Fung CD, Cheung PW, Ko WH, Fleming DG (1985) Micromachining and micropackaging of transducers. Elsevier, Amsterdam, p 41

Gui C, Albers H, Gardeniers JGE (1997) Fusion bonding of rough surfaces with polishing technique for silicon. J Microsys Technol 122–128

Guu YH (2005) AFM surface imaging of AISI D2 tool steel machined by the EDM process. Appl Surf Sci 242(3–4):245–250

Guu YH, Hocheng H (2001) High cycle fatigue of electrical-discharge machined AISI D2 tool steel. J Mater Prod Technol 16(6–7):642. doi:10.1504/IJMPT.2001.001286

Haisma J, Gijsbertus ACMS, Theo MM (1995) Surface preparation and phenomenological aspects of direct bonding. Philipp J Res 49:23–46

Imran F, Erwin B, Rik D (2005) Bonding strength tests between silicon wafers and duran tubes. Actuator Microsys, pp 936–939

Kutchoukov VG, Laugere F, van der Vlist W (2004) Fabrication of nanofluidic devices using glass-to-glass anodic bonding. J Non Cryst Solids, Sens Actuator A 114:521–527

Lee DJ, Byeong KJ, Jin J (1999) Effects of a hydrophilic surface in anodic bonding. J Micromech Microeng 9:313–318

Mitsushi I, Frederick WK Jr, Masayuki M et al (1993) Particle removal from silicon wafer surface in wet cleaning process. IEEE Trans Semicond Man 6:3

Plobi A et al (1999) Wafer direct bonding: tailoring adhesion between brittle materials. Mater Sci Eng R25(1–2):1–88

Qin-Yi T, Ulrich MG (1999) Wafer bonding and layer splitting for microsystems. J Adv Mater 17:1409–1425

Sayah A, Solignac D, Cueni T (2000) Development of novel low temperature bonding technologies for microchip chemical analysis applications. J App Phys Sens Actuator 84:103–108

Tung WH (1998) The relationship between white layer and residual stress induced by edm hole-drilling. Dissertation, National Cheng Kung University, Taiwan

Acknowledgments

This work has been partially funded by AsiaLink EU (ASIA-LINK-CN/ASIA-LINK/004 (81206)) project. M. Salvo, V. Casalegno and F. Rizzo are kindly acknowledged for mechanical tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Q., Chen, Q. & Ferraris, M. Optimization of thermal assisted direct bonding of soda-lime glasses for lab-on chip application. Microsyst Technol 16, 527–532 (2010). https://doi.org/10.1007/s00542-010-1025-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-010-1025-9