Abstract

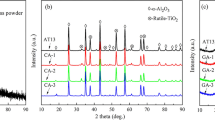

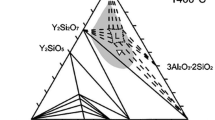

The present study examined how the microstructure and plasma-resistant characteristics of CaO–Al2O3–SiO2 (CAS) glass layers coated on sintered alumina substrates were affected by the applied sintering conditions. Coated layers were formed using a bar-coating method, subsequently subjected to the de-binding process, and then finally sintered at temperatures lower than the crystallization temperature of the glass, ranging from 950 to 1000 °C, for varying durations. The coated layer composed solely of CAS glass exhibited an etch rate approximately four times lower than that of alumina. The lowest etch rate of the CAS glass layer was 13.25 nm/min at 950 °C 15 min, showing the best plasma resistance. It was also found that the glass layers became increasingly crystallized with increasing temperature and duration, and this then reduced their plasma resistance. The etch rate of glass when crystalline phases were present was found to be 35.31 nm/min.

Similar content being viewed by others

References

G.S. May, C.J. Spanos, Fundamentals of Semiconductor Manufacturing and Process Control (John Wiley and Sons, 2006), pp. 98–102

N. Ito, T. Moriya, F. Uesugi, M. Matsumoto, S. Liu, Y. Kitayama, Reduction of particle contamination in plasma-etching equipment by dehydration of chamber wall. Jpn. J. Appl. Phys. 47(5R), 3630 (2008). https://doi.org/10.1143/JJAP.47.3630

K.-B. Kim, D.-M. Kim, J.-K. Lee, Y.-S. Oh, H.-T. Kim, H.-S. Kim, S.-M. Lee, Erosion behavior of YAG ceramics under fluorine plasma and their XPS analysis. J. Korean Ceram. Soc. 46(5), 456–461 (2009). https://doi.org/10.4191/KCERS.2009.46.5.456

D.-M. Kim, M.-R. Jang, Y.-S. Oh, S. Kim, S.-M. Lee, S.-H. Lee, Relative sputtering rates of oxides and fluorides of aluminum and yttrium. Surf. Coat. Technol. 309, 694–697 (2017). https://doi.org/10.1016/j.surfcoat.2016.11.007

J. Iwasawa, R. Nishimizu, M. Tokita, M. Kiyohara, K. Uematsu, Plasma-resistant dense yttrium oxide film prepared by aerosol deposition process. J. Amer. Ceram. Soc. 90(8), 2327–2332 (2007). https://doi.org/10.1111/j.1551-2916.2007.01738.x

D.-M. Kim, K.-B. Kim, S.-Y. Yoon, Y.-S. Oh, H.-T. Kim, S.-M. Lee, Effects of artificial pores and purity on the erosion behaviors of polycrystalline Al2O3 ceramics under fluorine plasma. J. Ceram. Soc. Jpn. 117(1368), 863–867 (2009). https://doi.org/10.2109/jcersj2.117.863

D.B. Graves, D. Humbird, Surface chemistry associated with plasma etching processes. Appl. Surf. Sci. 192(1–4), 72–87 (2002). https://doi.org/10.1016/S0169-4332(02)00021-1

Y. Sato, S. Shibata, R. Sakaida, K. Eriguchi, Characterization of residual defects in plasma-exposed Si Substrates using Cathodoluminescence and positron annihilation spectroscopy. The 17th International Workshop on Junction Technology 2017(IWJT). p.73–76. (2017). https://doi.org/10.23919/iwjt.2017.7966519

J.-H. Choi, H. Na, J. Park, H.-J. Kim, Plasma corrosion resistance of aluminosilicate galsses containing Ca, Y and B under fluorocarbon plasma with Ar+. J. Non. Cryst. Solids. 521, 119498 (2019). https://doi.org/10.1016/j.jnoncrysol.2019.119498

J.-H. Choi, H.-B. Park, H. Na, H.-J. Kim, Plasma corrosion resistance of RO-Al2O3-SiO2 (R: Alkaline earth) under fluorocarbon plasma with Ar+: II. Plasma resistant glass. Corros. Sci. 146, 247–253 (2019). https://doi.org/10.1016/j.corsci.2018.10.015

H. Na, J. Park, S.-C. Choi, H.-J. Kim, The effect of composition of Plasma resistance of CaO-Al2O3-SiO2 glasses under Fluorocarbon Plasma with Ar+. Appl. Surf. Sci. 476, 663–667 (2019). https://doi.org/10.1016/j.apsusc.2019.01.133

D.A. Schulz, A.W. Searcy, Vapor pressure and heat of sublimation of calcium fluoride1,2. J. Phys. Chem. 67(1), 103–106 (1963). https://doi.org/10.1021/j100795a023

B. Brunetti, V. Piacente, P. Scardala, Torsion vapor pressures and sublimation enthalpies of aluminum trifluoride and aluminum trichloride. J Chem. Eng. Data. 54(3), 940–944 (2009). https://doi.org/10.1021/je8007167

J.L. Lyman, T. Noda, Thermochemical properties of Si2F6 and SiF4 in gas and condensed phases. J. Phys. Chem. Ref. Data. 30(1), 165–186 (2001). https://doi.org/10.1063/1.1364519

H. Na, J. Park, D.-G. Kim, S.-C. Choi, H.-J. Kim, Comparison of plasma resistance between spray coating films and bulk of CaO-Al2O3-SiO2 glasses under CF4/O2/Ar plasma etching. J. Korean. Cryst. Growth Cryst Technol. 30(2), 66–72 (2020). https://doi.org/10.6111/JKCGCT.2020.30.2.066

A.D. French, M.S. Cintro´n, Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose. 20(1), 583–588 (2013). https://doi.org/10.1007/s10570-012-9833-y

A. Isogai, M. Usuda, Crystallinity indexes of cellulosic materials. Sen-I Gakkaishi. 46(8), 324–329 (1990). https://doi.org/10.2115/fiber.46.8_324

L. Segal, J.J. Creely, A.E. Martin, C.M. Conrad, An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffactometer. Text. Res. J. 29(10), 786–794 (1959). https://doi.org/10.1177/004051755902901003

R. Dimitrijević, V. Dondur, A. Kremenović, Thermally induced phase transformations of Ca-exchanged LTA and FAU zeolite frameworks: Rietveld refinement of the hexagonal CaAl2Si2O8 diphyllosilicate structure. Zeolites 16(4), 294–300 (1996). https://doi.org/10.1016/0144-2449(95)00154-9

J. Goldstein, D. Newbury, D. Joy, C. Lyman, P. Echlin, E. Lifshin, L. Sawyer, J. Michael, Scanning Electron Microscopy and X-Ray Microanalysis, 3rd edn. (Plenum Publishers, New York, 2003), pp. 65–72

J.-K. Lee, D.-S. Kim, S.-M. Lee, H.-S. Kim, Effect of rare-earth elements on the plasma etching behavior of the RE–Si–Al–O glasses. J. Non. Cryst. Solids. 358(5), 898–902 (2012). https://doi.org/10.1016/j.jnoncrysol.2011.12.082

C. steinbrüchel, Universal energy dependence of physical and ion-enhanced chemical etch yields at low ion energy. Appl. Phys. Lett. 55(19), 1960–1962 (1989). https://doi.org/10.1063/1.102336

D.C. Gray, I. Tepermeister, H.H. Sawin, Phenomenological modeling of ion-enhanced surface kinetics in fluorine-based plasma etching. J. Vac. Sci. Technol. B. 11(4), 1243–1257 (1993). https://doi.org/10.1116/1.586925

T.E.F.M. Standaert, C. Hedlund, E.A. Joseph, G.S. Oehrlein, Role of fluorocarbon film formation in the etching of silicon, silicon dioxide, silicon nitride, and amorphous hydrogenated silicon carbide. J. Vac. Sci. Technol. A. 22(1), 53–60 (2004). https://doi.org/10.1116/1.1626642

D.-M. Kim, S.-H. Lee, William B. Alexander, K.-B. Kim, Y.-S. Oh, S.-M. Kim, X-Ray photoelectron spectroscopy study on the interaction of yttrium-aluminum oxide with fluorine-based plasma. J. Am. Ceram. Soc. 94(10), 3455–3459 (2011). https://doi.org/10.1111/j.1551-2916.2011.04589.x

Acknowledgements

This work was supported by the World Class 300 Project R and D Support project (www.worldclass300.or.kr) funded by the Small and Medium Business Administration (SMBA, Korea). [Project Name “Development of Plasma-resistant Surface Treatment Technology for 3D Structures and Large-area Parts of Semiconductor/Display Fabrication Equipment].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jung, Y.S., Min, K.W., Choi, J.H. et al. Plasma-resistant characteristics according to sintering conditions of CaO–Al2O3–SiO2 glass coating layer. J. Korean Ceram. Soc. 59, 86–93 (2022). https://doi.org/10.1007/s43207-021-00149-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00149-x