Abstract

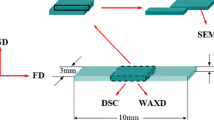

In this paper, PP (polypropylene) microstructures were manufactured by micro injection molding (MIM). The surface topography and internal defect under different process conditions were studied. An internal defect named “hollow” was observed in microstructures made without vacuum. To investigate the morphology (crystal and phase), the microstructures samples were cut to slices with 10 μm thickness along the filling direction. Results of polarized light microscopic observation reveal that these microstructures also represent “skin-core” morphology, i.e. a highly oriented non-crystalline skin layer, a shear zone with column crystal essentially parallel to the injection direction and a spherulites core. However the morphology distribution of microstructures is different from the macroscopic structure: the non-crystalline layer is much thinner, the ratio of skin layer (non-crystalline and column crystal layer) to core thickness is very big, there is no change of spherulites dimension from skin to center. So the microstructures must have a special mechanical performance differ from the macroscopic parts.

Similar content being viewed by others

References

Liou AC, Chen RH (2005) Injection molding of polymer micro- and sub-micron structures with high-aspect ratios. Int J Adv Manuf Technol 28:1097–1103

Kasanicka B, Muller M, Auhorn M et al (2006) Correlations between production process, states and mechanical properties of microstructures made of zirconia. Microsyst Technol 12:1133–1141

Gurhan K, Peter A, Michael BJ (1995) Microstructure and physical property control of injection moulded polypropylene. Plastics, Rubber Composites Pprocess Appl 23:71–85

Viana JC (2004) Development of the skin layer in injection moulding: phenomenological model. Polymer 45:993–10058

Ruprecht R, Gietzelt T, Miller K et al (2002) Injection molding of microstructured components from plastics, metals and ceramics. Microsyst Technol 8:351–358

Pantanik R, Coccorullo I, Speranza V et al (2005) Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Progress Polymer Sci 30:1185–1222

Ruprecht R, Hanemann T, Piotter V. et al (1998) Polymer materials for microsystem technologies. Microsyst Technol 5:44–48

Ralf T, Jorg K, Stefan S, et al (1996) Morphology and phase behaviour of blends of syndiotactic and isotactic polypropylene: 1. X-ray scattering, light microscopy, atomic force microscopy, and scanning electron microscopy. Polymer 37:2627–2634

Shimizu T, Murakoshi Y, Sano T et al (1998) Fabrication of micro–parts by high aspect ratio structuring and metal injection molding using the supercritical debinding methol. Microsyst Technol 5:90–92

Piotter V, Bauer W, Benzler T. et al (2002) Injection molding of components for Microsystems. Microsyst Technol 7:99–102

Michaeli W, Spennemann A, Gartner R (2002) New plastification concepts for micro injection moulding. Microsyst Technol 8:55–57

Liu ZY, Loh MH, Tor SB et al (2002) Micro-powder injection molding. J Mater Process Technol 127:165–168

Acknowledgments

The authors would like to thank the forty-ninth research institute of China Electron Science and Technology Combine Company for making the silicon insert.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, K.F., Lu, Z. Analysis of morphology and performance of PP microstructures manufactured by micro injection molding. Microsyst Technol 14, 209–214 (2008). https://doi.org/10.1007/s00542-007-0412-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-007-0412-3