Abstract

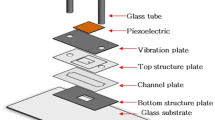

Both the workable micropump and microejector actuated by the shear mode PZT actuators are successfully fabricated. They are based on a similar design and the same process that uses UV-LIGA multilevel electroforming technology. The micropump consists of a vibration plate and a chamber plate while the microejector consists of the same vibration plate and a nozzle plate. The AZ 9260 positive photoresist is used as the electroforming mould. The two alternating steps, the photoresist patterning and nickel electroforming, make components form a quasi 3D (or 2.5D) multilevel microstructure. An over-electroforming technique is employed to form the nozzles in nozzle plate for the microejector. Some useful experimental data about the over-electroforming are proposed to predict and control the orifice diameter. The volume change of the chamber is estimated by both the numerical solution and actual measurement. The liquid ejection of the microejector is observed by a visualization system.

Similar content being viewed by others

References

Andersson H, Wijnggart Wvd, Nilsson P, Enoksson P, Stemme G (2001) A valve-less diffuser micropump for microfluidic analytical systems. Sensors Actuators B 72:259–265

Cuiy A, Lawes RA (1997) A new sacrificial layer process for the fabrication of micromechanical systems. J Micromech Microeng 7:128–130

Gobet J, Cardot F, Bergqvist J, Rudolf F (1993) Electrodeposition of 3D microstructures on silicon. J Micromech Microeng 3:123–130

Guckel H, Christenson TR, Skrobis KJ, Denton DD, Choi B, Lovell EG, Lee JW, Bajikar SS, Chapman TW (1990) Deep X-ray and UV lithographies for micromechanics. IEEE solid-state sensor and actuator workshop 4th technical digest, Hilton Head Island, South Carolina, pp 118–122

Huang L, Wang W, Murphy MC, Lian K, Ling ZG (2000) LIGA fabrication and test of a DC type magnetohydyodynamic (MHD) micropump. Microsyst Technol 6:235–240

Kamper KP, Ehrfeld W, Dopper J, Hessel V, Lehr H, Lowe H, Richter Th, Wolf A (1997) Microfluidic components for biological and chemical microreactors. IEEE international workshop on micro electro mechanical systems, MEMS ‘97, Nagoya, pp 338–343

Kohlmeier T, Seidemann V, Buttgenbach S, Gatzen HH (2002) Application of UV depth lithography and 3D-microforming for high aspect ratio electromagnetic microactuator components. Microsyst Technol 8:304–307

Kohlmeier T, Seidemann V, Buttgenbach S, Gatzen HH (2004) An investigation on technologies to fabricate microcoils for miniaturized actuator systems. Microsyst Technol 10:175–181

Lennon E, Ayela F (2002) Electrodeposition through thick photoresist moulds for the fabrication of a sharp chromium microtip. J Micromech Microeng 12:122–127

Liu C, Cui T, Zhou Z (2003) Modal analysis of a unimorph piezoelectrical transducer. Microsyst Technol 9:474–479

Loechel B (2000) Thick-layer resists for surface micromachining. J Micromech Microeng 10:108–115

Lorenz H, Paratte L, Luthier R, Rooij NF, Renaud P (1996) Low-cost technology for multilayer electroplated parts using laminated dry film resist. Sensors Actuators A 53(1–3):364–368

Steinert CP, Goutier I, Gutmanna O, Sandmaier H, Dauba M, Heij Bd, Zengerle R (2004) A highly parallel picoliter dispenser with an integrated novel capillary channel structure. Sensors Actuators A 116:171–177

Wang EN, Zhang L, Jiang L, Koo JM, Maveety JG, Sanchez EA (2004) Micromachined jets for liquid impingement cooling of VLSI chips. J Microelectromech Syst 13(5):833–842

Yang Y, Chang SC, Bharathan J, Liu J (2000) Organic/polymeric electroluminescent devices processed by hybrid ink-jet printing. J Mater Sci Mater Electron 11:89–96

Acknowledgements

The authors would like to thank the National Science Council of Taiwan for financially supporting this research under Contract no. NSC 92-2212-E-018-001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, S.C., Cheng, C.H. & Lin, Y.C. Fabrication of components for a valve-less micropump or microejector by multilevel electroforming technology. Microsyst Technol 13, 455–463 (2007). https://doi.org/10.1007/s00542-006-0209-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0209-9