Abstract

The effect of sweating simulation methods on clothing evaporative resistance was investigated in a so-called isothermal condition (T manikin = T a = T r ). Two sweating simulation methods, namely, the pre-wetted fabric “skin” (PW) and the water supplied sweating (WS), were applied to determine clothing evaporative resistance on a “Newton” thermal manikin. Results indicated that the clothing evaporative resistance determined by the WS method was significantly lower than that measured by the PW method. In addition, the evaporative resistances measured by the two methods were correlated and exhibited a linear relationship. Validation experiments demonstrated that the empirical regression equation showed highly acceptable estimations. The study contributes to improving the accuracy of measurements of clothing evaporative resistance by means of a sweating manikin.

Similar content being viewed by others

References

ASTM (2010) ASTM F 2370 standard test method for measuring the evaporative resistance of clothing using a sweating manikin. American Society for Testing and Materials (ASTM), Pennsylvania

Belghazi K, Elabbassi EB, Tourneux P, Libert JP (2005) Assessment of whole body and regional evaporative heat loss coefficients in very premature infants using a thermal mannequin: influence of air velocity. Med Phys 32:752–758

Burton AC, Edholm OG (1955) Man in a cold environment. Edward Arnold Ltd., London

Fan J, Chen Y, Zhang W (2001) A perspiring fabric thermal manikin: its development and use. Proceedings of the 4th International Meeting on Thermal Manikin (4IMM). EMPA, St. Gallen, pp 1–5

Havenith G, Bröde P, Candas V, den Hartog E, Kuklane K, Holmer I, Rossi RM, Richards M, Farnworth B, Wang X (2013) Evaporative cooling: effective latent heat of evaporation in relation to evaporation distance from the skin. J Appl Physiol 114:778–785

Holmér I (2004) Thermal manikin history and applications. Eur J Appl Physiol 92:614–618

Holmér I, Elnäs S (1981) Physiological evaluation of resistance to evaporative heat transfer by clothing. Ergonomics 24:63–74

ISO (2004a) ISO 15831 clothing—physiological effect—measurement of thermal insulation by means of a thermal manikin. International Organization for Standardization, Geneva

ISO (2004b) ISO 7933 ergonomics of the thermal environment—analytical determination and interpretation of heat stress using calculation of the predicted heat strain. International Organization for Standardization, Geneva

ISO (2005) ISO 7730. Moderate thermal environments—determination of the PMV and PPD indices and specification of the conditions for thermal comfort. International Organization for Standardization, Geneva, Switzerland

ISO (2007) Evaluation of cold environments—determination of required clothing insulation (IREQ). International Organization for Standardization, Geneva

Lu Y, Wang F, Peng H, Shi W, Song G (2015) Effect of sweating set rate on clothing real evaporative resistance determined on a sweating thermal manikin in a so-called isothermal condition (T air = T manikin = T r ). Int J Biometeorol. doi:10.1007/s00484-015-1029-3

McCullough EA (2001) Interlaboratory study of sweating thermal manikins. In: Richards MGM (ed) Proceedings of the 4th International Meeting on Thermal Manikin (4IMM). EMPA, St. Gallen, pp 1–6

Meinander H (1997) Experience with a sweating thermal manikin–ready for standard use? In: Nilsson H, Holmér I (eds) Proceedings of a European seminar on thermal manikin testing. Arbetslivsinstitutet, Solna, pp 38–42

Meinander H, Hellsten M (2004) The influence of sweating on the heat transmission properties of cold protective clothing studied with a sweating thermal manikin. Int J Occup Saf Ergon 10:263–269

Richards MGM, McCullough EA (2005) Revised interlaboratory study of sweating thermal manikins including results from the sweating agile thermal manikin. J ASTM Int 2:1–13

Ueno S, Sawada S (2012) Correction of the evaporative resistance of clothing by the temperature of skin fabric on a sweating and walking thermal manikin. Text Res J 82:1143–1156

Varheenmaa M (2014) A new generation sweating thermal manikin for the evaluation of the thermoregulation properties of protective clothing. In: Varheenmaa M (ed.) Proceedings of the 10th International Meeting on Thermal Manikin and Modelling (10i3m), Tampere, Finland, pp.1-5

Wang F (2009) A preliminary study on the wet cotton skin. Technical Report: Lund University, Sweden. Unpublished work

Wang F, Gao C, Kuklane K, Holmér I (2009) A study on evaporative resistances of two skins designed for thermal manikin Tore under different environmental conditions. J Fiber Bioeng Inform 1:301–305

Wang F, Kuklane K, Gao C, Holmér I (2010) Development and validity of a universal empirical equation to predict skin surface temperature on thermal manikins. J Therm Biol 35:197–203

Wang F, Gao C, Kuklane K, Holmér I (2011) Determination of clothing evaporative resistance on a sweating thermal manikin in an isothermal condition: heat loss method or mass loss method? Ann Occup Hyg 55:775–783

Wang F, del Ferraro S, Lin LY, Sotto Mayor T, Ribeiro M, Gao C, Kuklane K, Holmér I (2012a) Localised boundary air layer and clothing evaporative resistances for individual body segments. Ergonomics 55:799–812

Wang F, Kuklane K, Gao C, Holmér I (2012b) Effect of temperature difference between manikin and wet fabric skin surfaces on clothing evaporative resistance: how much error is there? Int J Biometeorol 56:177–182

Wang F, Annaheim S, Morrissey M, Rossi RM (2014a) Real evaporative cooling efficiency of one-layer tight-fitting sportswear in a hot environment. Scand J Med Sci Sports 24:e129–e139

Wang F, Havenith G, Mayor TS, Kuklane K, Léonard J, Zwolinska M, Hodder S, Wong C, Kishino J and Dai X (2014) Clothing real evaporative resistance determined by means of a sweating thermal manikin: a new round-study study. In: Varheenmaa M (ed.) Proceedings of the 10th International Meeting on Thermal Manikin and Modelling (10i3m), Tampere, Finland, pp.1–7

Wang F, Shi W, Lu Y, Song G, Rossi RM, Annaheim S (2015a) Effects of moisture content and clothing fit on clothing apparent ‘wet’ thermal insulation: a thermal manikin study. Text Res J. doi:10.1177/0040517515580527

Wang F, Zhang C, Lu Y (2015b) Correction of real evaporative heat loss on the wet fabric ‘skin’ of a sweating thermal manikin in a so-called isothermal condition (T air = T manikin = T r ). J Therm Biol 52:45–51

Acknowledgments

This study received no specific funding.

Author information

Authors and Affiliations

Corresponding author

Annex A: Correction of the clothing evaporative resistance determined in the so-called isothermal condition (T manikin = T a = T r )

Annex A: Correction of the clothing evaporative resistance determined in the so-called isothermal condition (T manikin = T a = T r )

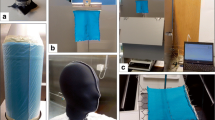

For the “Newton” sweating manikin, a fabric “skin” (the skin must be thin and tightly fitted to the manikin body; i.e., there should not be any air gap in between) should dress up the manikin when performing wet tests. During the wet test, this piece of fabric skin should be kept fully wetted either by buffering enough amount of water or by continuously supplying water. Evaporation occurring at the surface of this diffusive fabric skin will absorb heat from the skin. Unfortunately, the surface temperature of the fabric skin is not controlled. Therefore, there is a temperature difference between the controlled manikin surface and the wetted fabric skin surface. Thus, the skin will draw heat from the manikin surface through conduction, and in the so-called isothermal condition where T air = T manikin = T r , the fabric skin will also probably draw heat from the ambient environment through both convection and radiation due to the negative temperature difference (i.e., T sk,f < T air). The surface temperature at the fabric skin T sk,f may be calculated by Eq. (A-1)

where T sk,f is the surface temperature of the wetted fabric skin, °C; H manikin is the observed heat loss from the manikin, W/m2; and I sk,wet is the wet conductive thermal resistance of the wetted fabric skin, m2 K/W.

Wang et al. (2010) have developed a universal equation to estimate the wet fabric skin surface temperature. This equation has been further validated by Ueno and Sawada (2012). The equation reads

It should be noted that the value of 0.0132 m2 K/W for I sk,wet is dependent on the fabric skins construction and thickness; different values (e.g., 0.0092 m2 K/W reported by Ueno and Sawada (2012) were reported in other laboratories for their specific fabric skins.

The clothing standard evaporative resistance R et,standard should be calculated as

It should be noted that the prevailing way uses the evaporative heat loss observed on the manikin surface H manikin to calculate clothing real evaporative resistance. The clothing evaporative resistance (determined in the so-called isothermal condition) calculated by the prevailing heat loss method may be called as the standard evaporative resistance. However, in the so-called isothermal condition, the wet fabric skin-clothing system may gain heat from the environment. Thus, the heat loss observed on manikin H manikin is not equal to the actual energy H e used for water evaporation of the wet fabric skin-clothing system. The actual thermal energy used for water evaporation H e may be calculated by

where I t,wet is the wet thermal insulation of the tested clothing ensemble, m2 K/W.

The clothing thermal insulation decreases as it gets wet. Based on the meta-analysis (Wang et al. 2015a), the relationship between the increase of total clothing weight w t (in grams) and the reduction in the clothing thermal insulation ΔI t was further explored. The equation used for calculating the decrease of clothing thermal insulation reads

Thus, the clothing wet thermal insulation I t, wet should be calculated as

Combining Eqs. (A-2)–(A-6) with the Eq. (A-3), we can finally use the Eq. (A-7) to calculate the clothing real evaporative resistance (the air temperature in Eq. (A-7) was T air = 34.0 °C)

Rights and permissions

About this article

Cite this article

Lu, Y., Wang, F. & Peng, H. Effect of two sweating simulation methods on clothing evaporative resistance in a so-called isothermal condition. Int J Biometeorol 60, 1041–1049 (2016). https://doi.org/10.1007/s00484-015-1095-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00484-015-1095-6