Abstract

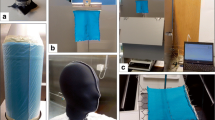

The ASTM F2370 (2010) is the only standard with regard to measurement of clothing real evaporative resistance by means of a sweating manikin. However, the sweating set-point is not recommended in the standard. In this study, the effect of sweating rate on clothing real evaporative resistance was investigated on a 34-zone “Newton” sweating thermal manikin in a so-called isothermal condition (T manikin = T a = T r). Four different sweating set rates (i.e., all segments had a sweating rate of 400, 800, 1200 ml/hr∙m2, respectively, and different sweating rates were assigned to different segments) were applied to determine the clothing real evaporative resistance of five clothing ensembles and the boundary air layer. The results indicated that the sweating rate did not affect the real evaporative resistance of clothing ensembles with the absence of strong moisture absorbent layers. For the clothing ensemble with tight cotton underwear, a sweating rate of lower than 400 ml/hr∙m2 is not recommended. This is mainly because the wet fabric “skin” might not be fully saturated and thus led to a lower evaporative heat loss and thereby a higher real evaporative resistance. For vapor permeable clothing, the real evaporative resistance determined in the so-called isothermal condition should be corrected before being used in thermal comfort or heat strain models. However, the reduction of wet thermal insulation due to moisture absorption in different test scenarios had a limited contribution to the effect of sweating rate on the real evaporative resistance.

Similar content being viewed by others

References

ASTM (2010) ASTM F2370 standard test method for measuring the evaporative resistance of clothing using a sweating manikin. American Society for Testing and Materials (ASTM), Pennsylvania

Fan J, Chen Y, Zhang W (2001) A perspiring fabric thermal manikin: its development and use. Proceedings of the 4th International Meeting on Thermal Manikin (4IMM). EMPA, St. Gallen, pp 1–5

Gao C, Holmér I (2006) Initial, transient and steady state evaporative resistance of impermeable protective clothing. Proceedings of the 6th International Meeting on Thermal Manikin and Modeling (6I3M). The Hong Kong Polytechnic University, Hong Kong, pp 253–261

Hall JF, Polte JW (1956) Effect of water content and compression on clothing insulation. J Appl Physiol 8:539–545

Holmér I (2004) Thermal manikin history and applications. Eur J Appl Physiol 92:614–618

Holmér I, Elnäs S (1981) Physiological evaluation of resistance to evaporative heat transfer by clothing. Ergonomics 24:63–74

Holmér I, Nilsson H (1995) Heated manikin as a tool for evaluating clothing. Ann Occup Hyg 39:809–818

ISO (2004a) ISO 15831 Clothing—physiological effect—measurement of thermal insulation by means of a thermal manikin. International Organization for Standardization, Geneva

ISO (2004b) ISO 7933 Ergonomics of the thermal environment—analytical determination and interpretation of heat stress using calculation of the predicted heat strain. International Organization for Standardization, Geneva

ISO (2005) ISO 7730 Moderate thermal environments—determination of the PMV and PPD indices and specification of the conditions for thermal comfort. International Organization for Standardization, Geneva

Lu Y, Wang F, Wan X et al. (2015) Clothing resultant thermal insulation determined on a movable thermal manikin. Part II: effects of wind and body movements on local insulation. Int J Biometeorol, doi: 10.1007/s00484-015-0959-0

McCullough EA (2001) Interlaboratory study of sweating thermal manikins. In: Richards MGM (ed) Proceedings of the 4th International Meeting on Thermal Manikin (4IMM). EMPA, St. Gallen, pp 1–6

Meinander H (1997) Experience with a sweating thermal manikin–ready for standard use? In: Nilsson H, Holmér I (eds) Proceedings of a European seminar on thermal manikin testing. Arbetslivsinstitutet, Solna, pp 38–42

Meinander H, Hellsten M (2004) The influence of sweating on the heat transmission properties of cold protective clothing studied with a sweating thermal manikin. Int J Occup Saf Ergon 10:263–269

Ueno S, Sawada S (2012) Correction of the evaporative resistance of clothing by the temperature of skin fabric on a sweating and walking thermal manikin. Text Res J 82:1143–1156

Varheenmaa M (2014) A new generation sweating thermal manikin for the evaluation of the thermoregulation properties of protective clothing. In: Varheenmaa M (ed.) Proceedings of the 10th International Meeting on Thermal Manikin and Modeling (10i3m), Tampere, Finland, pp.1–5

Wang F, Annaheim S, Morrissey M, Rossi RM (2014a) Real evaporative cooling efficiency of one-layer tight-fitting sportswear in a hot environment. Scand J Med Sci Sports 24:e129–e139

Wang F, Gao C, Kuklane K, Holmér I (2011) Determination of clothing evaporative resistance on a sweating thermal manikin in an isothermal condition: heat loss method or mass loss method? Ann Occup Hyg 55:775–783

Wang F, Havenith G, Mayor TS et al. (2014b) Clothing real evaporative resistance determined by means of a sweating thermal manikin: a new round-study study. In: Varheenmaa M (ed.) Proceedings of the 10th International Meeting on Thermal Manikin and Modeling (10i3m), Tampere, Finland, pp.1–7

Wang F, Kuklane K, Gao C, Holmér I (2010) Development and validity of a universal empirical equation to predict skin surface temperature on thermal manikins. J Therm Biol 35:197–203

Wang F, Kuklane K, Gao C, Holmér I (2012) Effect of temperature difference between manikin and wet fabric skin surfaces on clothing evaporative resistance: how much error is there? Int J Biometeorol 56:177–182

Wang F, Shi W, Lu Y, Song G, Rossi RM, Annaheim S (2015a) Effects of moisture content and air gap on clothing apparent “wet” thermal insulation: how much reduction is there? Text Res J, doi: 10.1177/0040517515580527

Wang F, Zhang C, Lu Y (2015b) Correction of the heat loss method for calculating clothing real evaporative resistance. J Therm Biol 52:45-51

Acknowledgments

This study was financially supported by projects from the Natural Science Foundation of Jiangsu Province (BK20130312).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y., Wang, F., Peng, H. et al. Effect of sweating set rate on clothing real evaporative resistance determined on a sweating thermal manikin in a so-called isothermal condition (T manikin = T a = T r). Int J Biometeorol 60, 481–488 (2016). https://doi.org/10.1007/s00484-015-1029-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00484-015-1029-3