Abstract

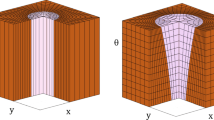

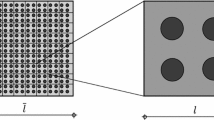

This article presents the details of a numerical technique for computing the macroscopic response of a material with a given micro-structure to arbitrary prescribed loading histories. The method uses classical concepts of homogenisation theory in combination with the finite element method and focusses on the computation of macroscopic yield surfaces and inelastic strain rates. It places no restrictions on the magnitude of deformation and allows arbitrary combinations of stress- or strain control including the prescription of histories of the Cauchy stress. The method is illustrated by analysing a model material, consisting of a non-linearly elastic matrix with stiff elasto-plastic inclusions, which exhibits macroscopically associative elasto-plastic material behaviour with finite elastic strains. Yield surfaces and the directions of plastic flow after a prior finite simple shear deformation are computed for this material and are shown to be consistent with an additive decomposition of the Eulerian strain rate into elastic and plastic parts and a suitable formulation of the normality rule in Cauchy stress space; a novel version of the latter is derived which is valid for an arbitrary reference configuration.

Similar content being viewed by others

References

Adhikari R, Huy T, Buschnakowski M, Knoll K (2004) Asymmetric ps-block-(ps-co-pb)-block-ps block copolymers: morphology formation and deformation behaviour. New J Phys 6: 28

Chen Y, Kulasegaram S (2009) Numerical modelling of fracture of particulate composites using sph method. Comput Mater Sci 47: 60–70

Gürses E, Becker M, Miehe C (2004) Numerical computation of anisotropically evolving yield surfaces based on micro-to macro transitions. Proc Appl Math Mech 4: 219–220

Halphen B, Nguyen Q (1975) Sur les materiaux standards generalises. J Mechanique 14: 39–63

Hill R (1972) On constitutive macro-variables for heterogeneous solids at finite strain. Proc R Soc London A 326: 131–147

Hill R (1978) Aspects of invariance in solid mechanics. In: Yih CS (ed) Advances in applied mechanics, vol 18. Academic Press, San Diego

Hill R (1984) On macroscopic effects of heterogeneity in elastoplastic media at finite strain. Math Proc Camb Phil Soc 95: 481–494

Hill R, Rice J (1973) Elastic potentials and the structure of inelastic constitutive laws. SIAM J Appl Math 25(3): 448–461

Il’yushin AA (1961) On a postulate of plasticity. Prikl Mat Mech 25: 503–507

Kouznetsova V, Brekelmans W, Baajens F (2001) An approach to micro-macro modelling of heterogeneous materials. Comput Mech 27: 37–48

Mehrabadi M, Nemat-Nasser S (1987) Some basic kinematical relations for finite deformation of continua. Mech Mat 6: 127–138

Miehe C, Koch A (2002) Computational micro-to-macro transitions of discretized microstructures undergoing small strains. Arch Appl Mech 72: 300–317

Miehe C, Schröder J, Schotte J (1999) Computational homogenization analysis in fintie plasticity. Simulation of texture develpopment in polycristalline materials. Comput Meth Appl Mech Eng 171: 387–418

Pardoen T, Hutchinson J (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48: 2467–2512

Prakash A, Lebensohn R (2009) Simulation of micromechanical behavior of polycrystals: finite elements versus fast fourier transforms. Modelling Simul Mater Sci Eng 17:1–16(064010)

Rice J (1971) Inelastic constitutive relations for solids: an internal variable theory and its application to metal plasticity. J Mech Phys Solids 19: 433–455

Schmidt I (2004) Deformation induced anisotropy in metal foams—modelling and simulation. Int J Solids Struct 41(24–25): 6759–6782

Schmidt I, Trondl A, Wonisch A, Kraft T (2010) Simulation of the material behaviour of metal-powder during compaction. J Process Mech Eng 224: 187–194

Temizer I, Wriggers P (2008) On the computation of the macroscopic tangent for multiscale volumetric homogenization problems. Comput Meth Appl Mech Eng 198: 495–510

Yuan Z, Fish J (2008) Toward realization of computational homogenization in practice. Int J Numer Meth Eng 73: 361–380

Author information

Authors and Affiliations

Corresponding author

Additional information

Dedicated to Prof. Dietmar Gross on his 70th birthday.

Rights and permissions

About this article

Cite this article

Schmidt, I. Numerical homogenisation of an elasto-plastic model-material with large elastic strains: macroscopic yield surfaces and the Eulerian normality rule. Comput Mech 48, 579–590 (2011). https://doi.org/10.1007/s00466-011-0601-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-011-0601-x