Abstract

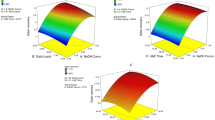

An investigation was carried out using sugarcane bagasse as the agricultural residue to study the optimization of xylanase production by solid-state fermentation. Maximum xylanase production (20.35 U/g substrate) was achieved by Bacillus substilis subsp. subtilis JJBS250 using ‘one variable at a time approach’ at pH 7.0, 40 °C after 48 h. After statistical optimization by response surface methodology (RSM) there was 4.82-fold improvement in xylanase production (98.16 U/g substrate). Further optimization of untreated and sodium carbonate pretreated sugarcane bagasse enzymatic hydrolysis was carried out using both bacterial (Bacillus substilis subsp. subtilis JJBS250) and fungal (Myceliophthora thermophila BJTLRMDU3) xylanases that showed high amount of reducing sugar liberation from untreated sugarcane bagasse (124.24 mg/g substrate) as compared to pretreated (76.23 mg/g substrate) biomass. Furthermore, biophysical characterization of untreated and sodium carbonate pretreated sugarcane bagasse using Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) and scanning electron microscopy (SEM), revealed the structural changes in the pretreated biomass.

Similar content being viewed by others

References

Camassola M, Dillon AJP (2010) Cellulases and xylanases production by Penicillium echinulatum grown on sugarcane bagasse in solid-state fermentation. Appl Biochem Biotechnol 162:1889–1900

Ghoshal G, Banerjee UC, Shivhare US (2015) Utilization of agrowaste and xylanase production in solid state fermentation. J Biochem Technol 6:1013–1024

Burlacu A, Cornea CP, Israel-Roming F (2016) Microbial xylanase: a review. Sci Bull Ser F Biotechnol 20:335–342

Pandey A, Soccol CR, Nigam P, Soccol VT (2000) Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresour Technol 74:69–80

Bala A, Singh B (2019) Development of an environmental-benign process for efficient pretreatment and saccharification of Saccharum biomasses for bioethanol production. Renew Energ 130:12–24

Kumar S, Haq I, Prakash J, Singh SK, Mishra S, Raj A (2017) Purification, characterization and thermostability improvement of xylanase from Bacillus amyloliquefaciens and its application in pre-bleaching of kraft pulp. 3 Biotech 7:20

Khusro A, Kaliyan BK, Al-Dhabi NA, Arasu MV, Agastian P (2016) Statistical optimization of thermo-alkali stable xylanase production from Bacillus tequilensis strain ARMATI. Electron J Biotechnol 22:16–25

Maciel GM, de Souza Vandenberghe LP, Haminiuk CWI, Fendrich RC, Della Bianca BE, da Silva Brandalize TQ, Pandey A, Soccol CR (2008) Xylanase production by Aspergillus niger LBP 326 in solid-state fermentation using statistical experimental designs. Food Technol Biotechnol 46:183–189

Alokika, Singh D, Singh B (2018) Utility of acidic xylanase of Bacillus subtilis subsp. subtilis JJBS250 in improving the nutritional value of poultry feed. 3 Biotech 8:503.

Jain J, Singh B (2016) Phytase production and development of an ideal dephytinization process for amelioration of food nutrition using microbial phytases. Appl Biochem Biotechnol 181:1485–1495

Dahiya S, Singh B (2019) Enhanced endoxylanase production by Myceliophthora thermophile with applicability in saccharification of agricultural substrates. 3 Biotech 9:214

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–429

Kim S, Holtzapple MT (2006) Effect of structural features on enzyme digestibility of corn stover. Bioresour Technol 97:583–591

Panwar D, Srivastava PK, Kapoor M (2014) Production, extraction and characterization of alkaline xylanase from Bacillus sp. PKD-9 with potential for poultry feed. Biocatal Agric Biotechnol 3:118–125

Addela IR, Gujjula R, Surender M, Nyapati S, Rudravaram R, Bhagam R (2015) Production and optimization of xylanase from Penicillium species in solid-state fermentation. Int J Rec Biotechmol 3:15–21

Saratale GD, Saratale RG, Kim SH, Kumar G (2018) Screening and optimization of pretreatments in the preparation of sugarcane bagasse feedstock for biohydrogen production and process optimization. Int J Hydrog Energ 43:11470–11483

Chandel AK, Antunes FA, Anjos V, Bell MJ, Rodrigues LN, Polikarpov I, de Azevedo ER, Bernardinelli OD, Rosa CA, Pagnocca FC, da Silva SS (2014) Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid–base pretreatment and ethanol production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol Biofuels 7:63

Alebiosu FA, Lawal AK, Olatope SO, Suberu YL, Shittu KA, Orji FA, Adelaja OD, Ugbana AI, Esan OA, Dike EN, Elemo GN (2015) Production of xylanases from fungal isolates by solid state fermentation using sugarcane bagasse. Int J Curr Microbiol App Sci 4:323–331

Irfan M, Nadeem M, Syed Q (2014) One-factor-at-a-time (OFAT) optimization of xylanase production from Trichoderma viridea-IR05 in solid-state fermentation. J Radiat Res Appl Sci 7:317–326

Ho LH, Heng KL (2015) Xylanase production by Bacillus subtilis in cost-effective medium using soybean hull as a part of medium composition under submerged fermentation (SmF) and solid-state fermentation (SsF). J Biodivers Bioprospect Dev 2:143

El-Gendy MMA, El-Bondkly AMA (2014) Optimization of solid state fermentation and leaching process parameters for improvement xylanase production by endophytic Streptomyces sp. ESRAA-301097. J Microb Biochem Technol 6:154–166

Sanghi A, Garg N, Sharma J, Kuhar K, Kuhad RC, Gupta VK (2008) Optimization of xylanase production using inexpensive agro-residues by alkalophilic Bacillus subtilis ASH in solid-state fermentation. World J Microbiol Biotechnol 24:633–640

El-Shishtawy RM, Mohamed SA, Asiri AM, Gomaa AM, Ibrahim IH, Al-Talhi HA (2014) Solid fermentation of wheat bran for hydrolytic enzymes production and saccharification content by a local isolate Bacillus megatherium. BMC Biotechnol 14:29

Kumar L, Nagar S, Kumar D, Garg N, Gupta VK (2013) Production of an alkali tolerant extracellular xylanase from Bacillus pumilus VLK-1 in solid state fermentation and its use in tomato juice clarification. Int J Cell Sci Biotechnol 2:1–10

Abdel-Sater MA, El-Said AHM (2001) Xylan-decomposing fungi and xylanolytic activity in agricultural and industrial wastes. Int Biodeterior Biodegrad 47:15–21

Norazlina I, Meenalosani N, Ku Halim KH (2013) Production of xylanase by Trichoderma sp. via solid state culture using sugarcane bagasse. Int J Energ Sci 3:99–105

Poorna AC, Prema P (2007) Production of cellulase-free endoxylanase from novel alkalophilic thermotolerant Bacillus pumilus by solid state fermentation and its application in waste paper recycling. Bioresour Technol 98:485–490

Bala A, Singh B (2017) Concomitant production of cellulase and xylanase by thermophilic mould Sporotrichum thermophile in solid state fermentation and their applicability in bread making. World J Microbiol Biotechnol 33:109

Kapoor M, Nair LM, Kuhad RC (2008) Cost-effective xylanase production from free and immobilized Bacillus pumilus strain MK001 and its application in saccharification of Prosopis juliflora. Biochem Eng J 38:88–97

Sharma KK, Kapoor M, Kuhad RC (2005) In vivo enzymatic digestion, in vitro xylanase digestion, metabolic analogues, surfactants and polyethylene glycol ameliorate laccase production from Ganoderma sp. kk-02. Lett Appl Microbiol 41:24–31

Singh B, Sataynarayana T (2006) A marked enhancement in phytase production by a thermophilic mould Sporotrichum thermophile using statistical designs in a cost-effective cane molasses medium. J Appl Microbiol 101:344–352

Kumar S, Satyanarayana T (2004) Statistical optimization of a thermostable and neutral glucoamylase production by a thermophilic mold Thermomucor indicae-seudaticae in solid-state fermentation. World J Microbiol Biotechnol 20:895–902

Chong G, Di J, Qian J, Wang C, He Y, Huo X, Wu C, Zhang L, Zhang Z, Tang Y, Ma C (2018) Efficient pretreatment of sugarcane bagasse via dilute mixed alkali salts (K2CO3/K2SO3) soaking for enhancing its enzymatic saccharification. Process Biochem 68:121–130

Nosratpour MJ, Karimi K, Sadeghi M (2018) Improvement of ethanol and biogas production from sugarcane bagasse using sodium alkaline pretreatments. J Environ Manag 226:329–339

You Y, Li P, Lei F, Xing Y, Jiang J (2017) Enhancement of ethanol production from green liquor–ethanol-pretreated sugarcane bagasse by glucose–xylose cofermentation at high solid loadings with mixed Saccharomyces cerevisiae strains. Biotechnol Biofuels 10:92

Acknowledgements

Mrs. Alokika acknowledges the financial assistance as senior Research fellowship (No. 09/382(0179)/2016-EMR-1) from Council of Scientific and Industrial Research, New Delhi during the tenure of this research work. We are thankful to Dr. Rajvinder Singh, Department of Genetics (Forensic Science), M. D. U., Rohtak for providing FTIR facility. We are also thankful to Dr. Anil Ohlan, Department of Physics, M. D. U., Rohtak for extending XRD facility for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alokika, Singh, B. Enhanced production of bacterial xylanase and its utility in saccharification of sugarcane bagasse. Bioprocess Biosyst Eng 43, 1081–1091 (2020). https://doi.org/10.1007/s00449-020-02306-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02306-8