Abstract

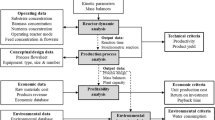

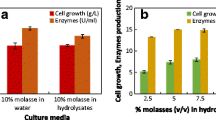

Fed-batch production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer using vinasses–molasses mixture is carried out in this work by implementing different process systems engineering tools. Two fed-batch strategies are tested experimentally at 5 L scale, considering only offline information: (1) offline optimizing control and (2) exponential feeding. Application of these strategies showed that different feeding profiles result in different dynamic behaviour, influencing both, yield and biopolymer properties. As offline-based feeding strategies do not consider information of the culture status, they cannot deal with uncertainties. Therefore, a closed loop control strategy was implemented, which uses biomass and substrate information predicted online by soft-sensors. Results demonstrated the technical feasibility to produce biopolymer using a 75/25%vol. vinasses–molasses mixture. Successful implementation of the soft-sensor-based control strategy was evidenced at pilot plant scale, where sugar concentration was kept almost constant for 14 h, while obtaining the desired copolymer. Thus, proposed control strategy could be of interest at industrial-scale.

Similar content being viewed by others

References

Ntaikou I, Koumelis I, Tsitsilianis C, Parthenios J, Lyberatos G (2018) Comparison of yields and properties of microbial polyhydroxyalkanoates generated from waste glycerol based substrates. Int J Biol Macromol 112:273–283

Nielsen C, Rahman A, Rehman AU, Walsh MK, Miller CD (2017) Food waste conversion to microbial polyhydroxyalkanoates. Microbial Biotechnol 10(6):1338–1352

Salakkam A, Webb C (2018) Production of poly (3-hydroxybutyrate) from a complete feedstock derived from biodiesel by-products (crude glycerol and rapeseed meal). Biochem Eng J 137:358–364

Bhattacharyya A, Pramanik A, Maji SK, Haldar S, Mukhopadhyay UK, Mukherjee J (2012) Utilization of vinasse for production of poly-3-(hydroxybutyrate-co-hydroxyvalerate) by Haloferax mediterranei. AMB Express 2(1):34

Pramanik A, Mitra A, Arumugam M, Bhattacharyya A, Sadhukhan S, Ray A et al (2012) Utilization of vinasse for the production of polyhydroxybutyrate by Haloarcula marismortui. Folia Microbiol 57(1):71–79

Khanna S, Srivastava AK (2006) Optimization of nutrient feed concentration and addition time for production of poly (β-hydroxybutyrate). Enzyme Microbial Technol 39(5):1145–1151

López JA, Bucalá V, Villar MA (2010) Application of dynamic optimization techniques for poly (β-hydroxybutyrate) production in a fed-batch bioreactor. Indus Eng Chem Res 49(4):1762–1769

Lopez-Arenas T, González-Contreras M, Anaya-Reza O, Sales-Cruz M (2017) Analysis of the fermentation strategy and its impact on the economics of the production process of PHB (polyhydroxybutyrate). Comput Chem Eng 107:140–150

Penloglou G, Vasileiadou A, Chatzidoukas C, Kiparissides C (2017) Model-based intensification of a fed-batch microbial process for the maximization of polyhydroxybutyrate (PHB) production rate. Bioprocess Biosyst Eng 40(8):1247–1260

Novak M, Koller M, Braunegg M, Horvat P (2015) Mathematical modelling as a tool for optimized PHA production. Chem Biochem Eng Q 29(2):183–220

Moran-Salazar RG, Sanchez-Lizarraga AL, Rodriguez-Campos J, Davila-Vazquez G, Marino-Marmolejo EN, Dendooven L, Contreras-Ramos SM (2016) Utilization of vinasses as soil amendment: consequences and perspectives. SpringerPlus 5(1):1007

Christofoletti CA, Escher JP, Correia JE, Marinho JFU, Fontanetti CS (2013) Sugarcane vinasse: environmental implications of its use. Waste Manage 33(12):2752–2761

Ortegón GP, Arboleda FM, Candela L, Tamoh K, Valdes-Abellan J (2016) Vinasse application to sugar cane fields. Effect on the unsaturated zone and groundwater at Valle del Cauca (Colombia). Sci Total Environ 539:410–419

Moraes BS, Triolo JM, Lecona VP, Zaiat M, Sommer SG (2015) Biogas production within the bioethanol production chain: use of co-substrates for anaerobic digestion of sugar beet vinasse. Bioresour Technol 190:227–234

Acosta-Cárdenas A, Alcaraz-Zapata W, Cardona-Betancur M (2018) Sugarcane molasses and vinasse as a substrate for polyhydroxyalkanoates (PHA) production. DYNA 85(206):220–225

Pant D, Adholeya A (2007) Biological approaches for treatment of distillery wastewater: a review. Bioresour Technol 98(12):2321–2334

Escalante-Sánchez A, Barrera-Cortés J, Poggi-Varaldo HM, Ponce-Noyola T, Baruch IS (2018) A soft sensor based on online biomass measurements for the glucose estimation and control of fed-batch cultures of Bacillus thuringiensis. Bioprocess Biosyst Eng 41(10):1471–1484

Mears L, Stocks SM, Sin G, Gernaey KV (2017) A review of control strategies for manipulating the feed rate in fed-batch fermentation processes. J Biotechnol 245:34–46

Oliveira R, Simutis R, de Azevedo SF (2004) Design of a stable adaptive controller for driving aerobic fermentation processes near maximum oxygen transfer capacity. J Process Control 14(6):617–626

Srinivasa BB, Moreshwar JM (2009) U.S. Patent Application No. 12/349,134

Pagliano G, Ventorino V, Panico A, Pepe O (2017) Integrated systems for biopolymers and bioenergy production from organic waste and by-products: a review of microbial processes. Biotechnol Biofuels 10(1):113

Aramvash A, Moazzeni Zavareh F, Gholami Banadkuki N (2018) Comparison of different solvents for extraction of polyhydroxybutyrate from Cupriavidus necator. Eng Life Sci 18(1):20–28

Heinrich D, Madkour MH, Al-Ghamdi MA, Shabbaj II, Steinbüchel A (2012) Large scale extraction of poly (3-hydroxybutyrate) from Ralstonia eutropha H16 using sodium hypochlorite. AMB Express 2(1):59

Amicarelli A, Quintero O, di Sciascio F (2014) Behavior comparison for biomass observers in batch processes. Asia-Pacific J Chem Eng 9(1):81–92

Chatzidoukas C, Penloglou G, Kiparissides C (2013) Development of a structured dynamic model for the production of polyhydroxybutyrate (PHB) in Azohydromonas lata cultures. Biochem Eng J 71:72–80

Ochoa S (2016) A new approach for finding smooth optimal feeding profiles in fed-batch fermentations. Biochem Eng J 105:177–188

Mozumder MSI, De Wever H, Volcke EI, Garcia-Gonzalez L (2014) A robust fed-batch feeding strategy independent of the carbon source for optimal polyhydroxybutyrate production. Process Biochem 49(3):365–373

Mohapatra S, Mohanta PR, Sarkar B, Daware A, Kumar C, Samantaray DP (2017) Production of polyhydroxyalkanoates (PHAs) by Bacillus strain isolated from waste water and its biochemical characterization. Proc Natl Acad Sci India Sect B Biol Sci 87(2):459–466

Avella M, Martuscelli E, Raimo M (2000) Review properties of blends and composites based on poly (3-hydroxy) butyrate (PHB) and poly (3-hydroxybutyrate-hydroxyvalerate)(PHBV) copolymers. J Mater Sci 35(3):523–545

Kulkarni SO, Kanekar PP, Nilegaonkar SS, Sarnaik SS, Jog JP (2010) Production and characterization of a biodegradable poly (hydroxybutyrate-co-hydroxyvalerate)(PHB-co-PHV) copolymer by moderately haloalkalitolerant Halomonas campisalis MCM B-1027 isolated from Lonar Lake, India. Bioresour Technol 101(24):9765–9771

Veloso AC, Ferreira EC (2017) Online analysis for industrial bioprocesses: broth analysis. In: Larroche C, Ángeles Sanromán M, Du G, Pandey A (eds) Current developments in biotechnology and bioengineering. Elsevier, Amsterdam, pp 679–704

Chéruy A (1997) Software sensors in bioprocess engineering. J Biotechnol 52(3):193–199

Acknowledgements

Financial support from COLCIENCIAS through the research project with contract number FP44842-064-2015 is gratefully acknowledged. Authors gratefully acknowledge the support given by the research group Laboratorio de Investigación en Polímeros at University of Antioquia, where the polymer characterization was carried out.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

García, C., Alcaraz, W., Acosta-Cárdenas, A. et al. Application of process system engineering tools to the fed-batch production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) from a vinasses–molasses Mixture. Bioprocess Biosyst Eng 42, 1023–1037 (2019). https://doi.org/10.1007/s00449-019-02102-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02102-z