Abstract

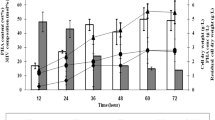

This study reports an efficient fed-batch strategy to improve poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) [P(3HB-co-3HV-co-4HB)] terpolymer production by Cupriavidus sp. USMAA2-4 with enhanced mechanical properties in bioreactor. The cultivations have been performed by combining oleic acid with γ-butyrolactone at different concentration ratios with 1-pentanol at a fixed concentration. The batch and fed-batch fermentations have resulted in P(3HB-co-3HV-co-4HB) with compositions of 9–35 mol% 3HV and 4–24 mol% 4HB monomers. The DO-stat fed-batch fermentation strategies have significantly improved the production with a maximum 4.4-fold increment of cell dry weight (CDW). Besides, appropriate feeding of the substrates has resulted in an increment of terpolymer productivity from 0.086–0.347 g/L/h, with a significantly shortened cultivation time. The bacterial growth and terpolymer formation have been found to be affected by the concentration of carbon sources supplied. Characterization of P(3HB-co-3HV-co-4HB) has demonstrated that incorporation of 3HV and 4HB monomer has significantly improved the physical and thermodynamic properties of the polymers, by reducing the polymer’s crystallinity. The tensile strength, Young’s modulus of the terpolymer has been discovered to increase with the increase of M w. The fed-batch fermentation strategies employed in this study have resulted in terpolymers with a range of flexible materials having improved tensile strength and Young’s modulus as compared to the terpolymer produced from batch fermentation. Possession of lower melting temperature indicates an enhanced thermal stability which broadens the polymer processing window.

Similar content being viewed by others

References

Sudesh K, Iwata T (2008) Sustainability of biobased and biodegradable plastics. Clean 35:433–442

Ojumu TV, Yu J, Solomon BO (2004) Production of polyhydroxyalkanoates, a bacterial biodegradable polymer. Afr J Biotechnol 3:18–24

Braunegg G, Lefebvre G, Genser KF (1998) Polyhydroxyalkanoates, biopolyesters from renewable resources: physiological and engineering aspects. J Biotechnol 65:127–161

Ramadas NV, Singh SK, Soccol CR, Pandey (2009) A Polyhydroxybutyrate production using agro-industrial residue as substrate by Bacillus sphaericus NCIM 5149. Braz Arch Biol Technol 52:17–23

Mumtaz T, Yahaya NA, Aziz SA, Rahman NAA, Yee PL, Shirai Y, Hassan MA (2010) Turning waste to wealth-biodegradable plastics polyhydroxyalkanoates from palm oil mill effluent—a Malaysian perspective. J Clean Prod 18:1393–1402

Khanna S, Srivastava AK (2005) A simple structured mathematical model for biopolymer (PHB) production. Biotechnol Progr 21:830–838

Huang TY, Duan KJ, Huang SY, Chen CW (2006) Production of polyhydroxyalkanoates from inexpensive extruded rice bran and starch by Haloferax mediterranei. J Ind Microbiol Biotechnol 33:701–706

Lee Y, Lee SH, Lee SY (1999) Fed-batch culture of Aeromonas hydrophila for the production of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) using two carbon sources. Biotechnol Bioproc E 4:195–198

Yamane T, Chen XF, Ueda S (1996) Growth-associated production of Poly(3-hydroxyvalerate) from n-pentanol by methylotrophic bacterium, Paracoccus denitrificans. Appl Environ Microb 62:380–384

Steinbűchel A, Fűchtenbusch B (1998) Bacterial and other biological systems for polyester production. Trends Biotechnol 16:419–427

Amirul AA, Yahya ARM, Sudesh K, Azizan MNM, Majid MIA (2008) Biosynthesis of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymer by Cupriavidus sp. USMAA1020 isolated from Lake Kulim, Malaysia. Bioresour Technol 99:4903–4909

Chung A, Liu Q, Ouyang SP, Wu Q, Chen GQ (2009) Microbial production of 3-hydroxydodecanoic acid by pha operon and fadBA knockout mutant of Pseudomonas putida KT2442 harboring tesB gene. Appl Microbiol Biotechnol 83:513–519

Fukui T, Suzuki M, Tsuge T, Nakamura S (2009) Microbial synthesis of poly((R)-3-hydroxybutyrate-co-3-hydroxypropionate) from unrelated carbon sources by engineered Cupriavidus necator. Biomacromol 10:700–706

Faezah AN, Rahayu A, Vigneswari S, Majid MIA, Amirul AA (2011) Regulating the molar fraction of 4-hydroxybutyrate in poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by biological fermentation and enzymatic degradation. World J Microb Biotechnol 27:2455–2459

William SF, Martin DP (2002) Applications of PHAs in medicine and pharmacy. Wiley-VCH Verlag GmbH, Germany

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci 25:1503–1555

Choi J-I, Lee SY (1999) High level production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by fed-batch culture of recombinant Escherichia coli. Appl Environ Microbiol 65:4363–4368

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Shantini K, Yahya ARM, Amirul AA (2012) Empirical modeling development for integrated process optimization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) production. J Appl Polym Sci 125:2155–2162

Shantini K, Yahya ARM, Amirul AA (2015) Influence of feeding and controlled dissolved oxygen level on production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Cupriavidus sp. USMAA2-4 and its characterization. Appl Biochem Biotechnol 176:1315–1334

Huong K-H, Shantini K, Sharmini R, Amirul AA (2017) Exploring the potential of 1-pentanol and oleic acid for optimizing the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer by Cupriavidus sp. USMAA1020. Arabian J Sci Eng 42:2313–2320

Amirul AA, Yahya ARM, Sudesh K, Azizan MNM, Majid MI (2008) Biosynthesis of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymer by Cupriavidus sp. USMAA1020 isolated from Lake Kulim, Malaysia. Bioresour Technol 99:4903–4909

Choi J, Lee SY (1999) Factors affecting the economics of polyhydroxyalkanoates production by bacterial fermentation. Appl Microbiol Biotechnol 51:13–21

Fahima Azira TM, Nursolehah AA, Norhayati Y, Majid MIA, Amirul AA (2011) Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) terpolymer by Cupriavidus sp. USMAA2-4 through two-step cultivation process. World J Microbiol Biotechnol 27:2287–2295

Rahayu A, Zaleha Z, Yahya ARM, Majid MIA, Amirul AA (2008) Production of copolymer poly(3-hydroxybutyrate-co-4-hydroxybutyrate) through a one-step cultivation process. World J Microbiol Biotechnol 24:2403–2409

Huong KH, Yahya ARM, Amirul AA (2014) Pronounced synergistic influence of mixed-substrate cultivation on single-step copolymer P(3HB-co-4HB) biosynthesis with a wide range of 4HB monomer composition. J Chem Technol Biotechnol 89:1023–1029

Huong KH, Kannusamy S, Lim SYH, Amirul AA (2015) Biosynthetic enhancement of single-stage poly(3-hydroxybutyrate-co-4-hydroxybutyrate) production by manipulating the substrate mixtures. J Ind Microbial Biotechnol 42:1291–1297

Nursolehah AA, Sipaut CS, Amirul AA (2012) Improvement of the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) terpolyester by manipulating the culture condition. J Chem Technol Biotechnol 87:1607–1614

Amirul AA, Syairah SN, Yahya ARM, Azizan MN, Majid MIA (2008) Synthesis of biodegradable polyesters by Gram negative bacterium isolated from Malaysian environment. World J Microb Biotechnol 24:1327–1332

Braunegg G, Sonnleitner B, Lafferty RM (1978) A rapid gas chromatography method for determination of the poly-β-hydroxybutyric acid biomass. Eur J Appl Microbiol Biotechnol 6:29–37

Loo CY, Lee WH, Tsuge T, Doi Y, Sudesh K (2005) Biosynthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) from palm oil products in a Wautersia eutropha mutant. Biotechnol Lett 27:1405–1410

Shantini K, Bhubalan K, Yahya ARM, Amirul AA (2013) Productivity increment of biodegradable and biorenewable copolymer containing 3-hydroxyvalerate monomer initiated by alcohols as precursor substrates. J Chem Technol Biotechnol 88:1364–1370

Verlinden RAJ, Hill DJ, Kenward MA, Williams CD, Radecka I (2007) Bacterial synthesis of biodegradable polyhydroxyalkanoates. J Appl Microbiol 102:1437–1449

Huong KH, The CH, Abdullah, AAA (2017) Microbial-based synthesis of highly elastomeric biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate) thermoplastic. Int J bio Macromol 101:983–995

Madden LA, Anderson AJ, Asrar J, Berger P, Garrett P (2000) Production and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) synthesized by Ralstonia eutropha in fed-batch cultures. Polym 41:3499–3505

Tsuge T (2016) Fundamental factors determining the molecular weight of polyhydroxyalkanoates during biosynthesis. Polym J 48:1051–1057

Madden LA, Anderson AJ, Shah DJ, Asrar J (1999) Chain termination in polyhydroxyalkanoates synthesis: involvement of exogenous hydroxy-compounds as chain transfer agents. Int J bio Macromol 25:43–53

Department of Chemical Engineering, Lund University, Sweden (2010) Influence of operating conditions on fed-batch production of polyhydroxyalkanoates in a mixed culture. http://www.chemeng.lth.se/exjobb/E508.pdf. Accessed 15 July 2017

Serafim LS, Lemos PC, Torres C, Reis MAM, Ramos AM (2008) The influence of process parameters on the characteristics of polyhydroxyalkanoates produced by mixed cultures. Macromol Biosci 8:355–366

Noda I, Green PR, Satkowski MM, Schechtman LA (2005) Preparation and properties of a novel class of polyhydroxyalkanoate copolymers. Biomacromol 6:580–586

Yoshie N, Saito M, Inoue Y (2001) Structural transition of lamella crystals in a isomorphous copolymer, poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Macromol 34:8953–8960

Koller M, Hesse P, Bona R, Kutschera C, Atlic A, Braunegg G (2007) Biosynthesis of high quality polyhydroxyalkanoate co- and terpolyester for potential medical application by the archaeon Haloferax mediterranei. Macromol Symp 253:33–39

Jadhav NR, Gaikwad VL, Nair KJ, Kadam HM (2009) Glass transition temperature: basics and application in pharmaceutical sector. Asian J Pharma 3:82–89

Nakamura S, Doi Y, Scandoila M (1992) Microbial synthesis and characterization of poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Macromol 25:4237–4241

Kang CK, Kusaka S, Doi Y (1995) Structure and properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) produced by Alcaligenes latus. Biotechnol Lett 15:583–588

Chai HL, Yahya ARM, Majid MIA, Amirul AA (2009) Microbial synthesis of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymer by Cupriavidus sp. USMAA2-4 through a two-step cultivation process. African J Biotechnol 8:4189–4196

Huong KH, Azuraini MJ, Aziz NA, Amirul AA (2017) Pilot scale production of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) biopolymers with high molecular weight and elastomeric properties. J Biosci Bioeng 124:76–83

Bugnicourt E, Cinelli P, Lazzeri A, Alvarez V (2014) Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging. Express Polym Lett 8:2–14

Chanprateep S, Buasri K, Muangwong A, Utiswannakul P (2010) Biosynthesis and biocompatibility of biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Polym Degrad Stab 95:2003–2012

Hablot E, Bordes P, Pollet E, AvéRous L (2008) Thermal and thermo-mechanical degradation of poly(3-hydroxybutyrate)-based multiphase systems. Polym Degrad Stab 93:413–421

Chanprateep S, Kulpreecha S (2006) Production and characterization of biodegradable terpolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) by Alcaligenes sp. A-04. J Biosci Bioeng 101:51–56

Martin DP, Williams SF (2003) Medical applications of poly-4-hydroxybutyrate: a strong flexible absorbable biomaterial. Biochem Eng J 16:97–105

Acknowledgements

The authors acknowledge the research grant (Science Fund, 02-01-05-SF0363) provided by Ministry of Science, Technology and Innovation Malaysia (MOSTI) that has supported this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Aziz, N.A., Huong, KH., Sipaut, C.S. et al. A fed-batch strategy to produce high poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) terpolymer yield with enhanced mechanical properties in bioreactor. Bioprocess Biosyst Eng 40, 1643–1656 (2017). https://doi.org/10.1007/s00449-017-1820-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1820-0