Abstract

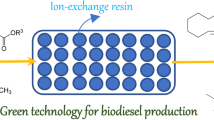

The transesterification of coconut oil with ethanol catalyzed by Burkholderia cepacia lipase immobilized on polysiloxane–polyvinyl alcohol was performed in a continuous flow. The experimental design consisted of a two-stage packed-bed reactor incorporating a column with cationic resin (Lewatit GF 202) to remove the glycerol formed as by-product and the reactor performance was quantified for three different flow rates corresponding to space-times from 10 to 14 h. The influence of space-time on the ethyl ester (FAEE) concentrations, yields and productivities was determined. The reactor operation was demonstrated for space-time of 14 h attaining FAEE concentrations of 58.5 ± 0.87 wt%, FAEE yields of 97.3 ± 1.9 % and productivities of 41.6 ± 1.0 mgester g −1medium h−1. Biodiesel purified samples showed average kinematic viscosity values of 5.5 ± 0.3 mm2 s−1 that meet the criteria established by the American National Standard ASTM (D6751). The immobilized lipase was found to be stable regarding its morphological and catalytic characteristics, showing half-life time (t 1/2) around 1540 h. The continuous packed-bed reactor connected in series with simultaneous glycerol removal has a great potential to attain high level of transesterification yields, raising biodiesel productivity.

Similar content being viewed by others

References

Basha SA, Gopal KR, Jebaraj SA (2009) Review on biodiesel production, combustion, emissions and performance. Renew Sustain Energy Rev 13:1628–1634

Hama S, Kondo A (2013) Enzymatic biodiesel production: an overview of potential feedstocks and process development. Bioresour Technol 135:386–395

Christopher LP, Kumar H, Zambare VP (2014) Enzymatic biodiesel: challenges and opportunities. Appl Energy 119:497–520

Atadashi IM, Aroua MK, Aziz AA (2011) Biodiesel separation and purification: a review. Renew Energy 36:437–443

Poppe JK, Fernandez-Lafuente R, Rodrigues RC, Ayub MAZ (2015) Enzymatic reactors for biodiesel synthesis: present status and future prospects. Biotechnol Adv 33:511–525

Chisti Y (2006) Bioreactor design. In: Ratledge C, Kristiansen B (eds) Basic biotechnology, 3rd edn. Cambridge University Press, Cambridge, pp 181–200

Simões AS, Ramos L, Freitas LT, Santos JC, Zanim GM, De Castro HF (2015) Performance of an enzymatic packed bed reactor running on babassu oil to yield fatty ethyl esters (FAEE) in a solvent-free system. Biofuel Res J. 2:242–247

Zhao Z, Qi F, Yuan C, Du W, Liu D (2015) Lipase-catalyzed process for biodiesel production: enzyme immobilization, process simulation and optimization. Renew Sustain Energy Rev 44:182–197

Gog A, Roman M, Tosa M, Paizs C, Irimie FD (2012) Biodiesel production using enzymatic transesterification—current state and perspectives. Renew Energy 39:10–16

Al-Zuhair S (2007) Production of biodiesel: possibilities and challenges. Biofuels Bioprod Bioref 1:57–66

Royon D, Daz M, Ellenrieder G, Locatelli S (2007) Enzymatic production of biodiesel from cotton seed oil using t-butanol as a solvent. Bioresour Technol 98:648–653

Dors G, Freitas L, Mendes AA, Furigo A, De Castro HF (2012) Transesterification of palm oil catalyzed by Pseudomonas fluorescens lipase in a packed-bed reactor. Energy Fuels 26:5977–5982

Wang Y, Wang X, Liu Y, Ou S, Tan Y, Tang S (2009) Refining of biodiesel by ceramic membrane separation. Fuel Process Technol 90:422–427

Hama S, Tamalampudi S, Yoshida A, Tamadani N, Kuratani N, Noda H, Fukuda H, Kondo A (2011) Enzymatic packed-bed reactor integrated with glycerol-separating system for solvent-free production of biodiesel fuel. Biochem Eng J 55:66–71

Fidalgo WRR, Teixeira LF, Santos JC, De Castro HF (2014) Estabelecimento das condições operacionais para a síntese de biodiesel catalisada por Novozym® 435 em reator de leito fluidizado. Blucher Chemical Engineering Proceedings, v.1, n.2, p.2173-2180. São Paulo: Blucher.; ISSN 2359-1757. doi:10.5151/chemeng-cobeq2014-1551-18707-155999

Product information Lewatit GF-202. http://www.lenntech.com/Data-sheets/Lewatit-GF-202-L.pdf. Accessed Feb 2016

Stamenkovic OS, Velickovic AV, Veljkovic BV (2011) The production of biodiesel from vegetable oils by ethanolysis: current state and perspectives. Fuel 90:3141–3155

Carvalho AKF, Da Rós PCM, Freitas L, Andrade GSS, Zanin GM, De Castro HF (2013) Assessing the potential non-edible oils and residual fat to be used as a feedstock in the enzymatic ethanolysis reaction. Ind Crop Prod 50:485–493

Da Rós PCM, Silva GAM, Mendes AA, Santos JC, De Castro HF (2010) Evaluation of the catalytic properties of Burkholderia cepacia lipase immobilized on non-commercial matrices to be used in biodiesel synthesis from different feedstocks. Bioresour Technol 101:5508–5516

Soares CMF, Castro HF, Moraes FF, Zanin GM (1999) Characterization and utilization of Candida rugosa lipase immobilized on controlled pore silica. Appl Biochem Biotechnol 77–9:745–757

Fogler HS (2002) Distribuições de Tempos de Residência para Reatores Químicos. In: Fogler HS (ed) Elementos de engenharia das reações químicas, 3rd edn. LTC, Rio de Janeiro

Urioste D, Castro MBA, Biaggio FC, De Castro HF (2008) Synthesis of chromatographic standards and establishment of a method for the quantification of the fatty ester composition of biodiesel from babassu oil. Quim Nova 31:407–412

Xu Y, Norbdblad M, Nielsen PM, Brask J, Woodley JM (2011) In situ visualization and effect of glycerol in lipase-catalyzed ethanolysis of rapeseed oil. J Mol Catal B Enzym 72:213–219

Noureddini H, Gao X, Philkana RS (2005) Immobilized Pseudomonas cepacia lipase for biodiesel fuel production from soybean oil. Bioresour Technol 96:769–777

Halim SFA, Kamaruddin AH, Fernando WJN (2009) Continuous biosynthesis of biodiesel from waste cooking palm oil in a packed bed reactor: optimization using response surface methodology (RSM) and mass transfer studies. Bioresour Technol 100:710–716

Wang X, Liu X, Zhao C, Yi Ding Y, Xu P (2011) Biodiesel production in packed-bed reactors using lipase—nanoparticle biocomposite. Bioresour Technol 102:6352–6355

Acknowledgments

The authors gratefully acknowledge the financial support of CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico-Process Number 475403/2012-6) and CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Costa e Silva, W., Freitas, L., Oliveira, P.C. et al. Continuous enzymatic biodiesel production from coconut oil in two-stage packed-bed reactor incorporating an extracting column to remove glycerol formed as by-product. Bioprocess Biosyst Eng 39, 1611–1617 (2016). https://doi.org/10.1007/s00449-016-1636-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1636-3