Abstract

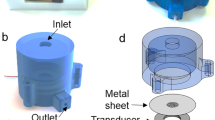

We describe a simple and efficient fabrication method for generating microfluidic channels with a circular cross-sectional geometry by exploiting the reflow phenomenon of a thick positive photoresist. Initial rectangular shaped positive photoresist micropatterns on a silicon wafer, which were fabricated by a conventional photolithography process, were converted into a half-circular shape by tuning the temperature to around 105 °C. Through optimization of the reflow conditions, we could obtain a perfect circular micropattern of the positive photoresist, and control the diameter in a range from 100 to 400 μm. The resultant convex half-circular photoresist was used as a template for fabricating a concave polydimethylsiloxane (PDMS) through a replica molding process, and a circular PDMS microchannel was produced by bonding two half-circular PDMS layers. A variety of channel dimensions and patterns can be easily prepared, including straight, S-curve, X-, Y-, and T-shapes to mimic an in vivo vascular network. To form an endothelial cell layer, we cultured primary human umbilical vein endothelial cells inside circular PDMS microchannels, and demonstrated successful cell adhesion, proliferation, and alignment along the channel.

Similar content being viewed by others

References

Auroux PA, Iossifidis D, Reyes DR, Manz A (2002) Anal Chem 74:2637–2652

Takayama S, Ostuni E, LeDuc P, Naruse K, Ingber DE, Whitesides GM (2001) Nature 411:1016

Lucchetta EM, Lee JH, Fu LA, Patel NH, Ismagilov RF (2005) Nature 434:1134–1138

Dittrich PS, Manz A (2006) Nat Rev 5:210–218

Kang L, Chung BG, Langer R, Khademhosseini (2008) Drug Discov Today 13:1–13

Wu MH, Huang SB, Lee GB (2010) Lab Chip 10:939–956

Kvietys PR, Granger DN (1997) Am J Physiol Gastrointest Liver Physiol 273:G1189–G1199

Young EW, Simmons CA (2010) Lab Chip 10:143–160

Ades EW, Candal FJ, Swerlick RA, George VG, Summers S, Bosse DC, Lawley TJ (1992) J Invest Dermatol 99:683–690

Gerritsen ME (1987) Bioichem Pharmacol 36:2701–2711

Lee JS (2000) Ann Biomed Eng 28:1–13

Wang GJ, Lin YC, Hsu SH (2010) Biomed Microdevices 12:841–848

Borenstein JT, Tupper MM, Mack PJ, Weinberg EJ, Khalil AS, Hsiao J, Garcia-Cardena G (2010) Biomed Microdevices 12:71–79

Becker H, Locascio LE (2002) Talanta 56:267–287

Wang GJ, Ho KH, Hsu SH, Wang KP (2007) Biomed Microdevices 9:657–663

Grosse A, Grewe M, Fouckhardt H (2001) J Micromech Microeng 11:257–262

Yang LJ, Chen YT, Kang SW, Wang YC (2004) Int J Mach Tool Manu 44:1109–1114

Futai N, Gu W, Takayama S (2004) Adv Mater 16:1320–1323

Wilson ME, Kota N, Kim Y, Wang Y, Stolz DB, LeDuc PR, Ozdoganlar OB (2011) Lab Chip 11:1550–1555

Song SH, Lee CK, Kim TJ, Shin IC, Jun SC, Jung HI (2010) Microfluid Nanofluid 9:533–540

Fiddes LK, Raz N, Srigunapalan S, Tumarkan E, Simmons CA, Wheeler AR, Kumacheva E (2004) Biomaterials 31:3459–3464

Lee SH, Kang DH, Kim HN, Suh KY (2010) Lab Chip 10:3300–3306

O’Neill FT, Sheridan JT (2002) Optik 113:391–404

Bauer J, Drescher G, Illig M (1996) J Vac Sci Technol B 14:2485–2492

Voinov OV (1999) J Appl Mech Tech Phys 40:86–92

Kubota Y, Kleinman HK, Martin GR, Lawley TJ (1988) J Cell Biol 107:1589–1598

Young EW, Wheeler AR, Simmons CA (2007) Lab Chip 7:1759–1766

Tanaka Y, Kikukawa Y, Sato K, Sugii Y, Kitamori T (2007) Anal Sci 23:261–266

Khan OF, Sefton MV (2011) Biomed Microdevices 13:69–87

Hsu S, Thakar R, Liepmann D, Li S (2005) Biochem Biophys Res Commun 337:401–409

Li S, Chen BP, Azuma N, Hu YL, Wu SZ, Sumpio BE, Shyy JY, Chien S (1999) J Clin Invest 103:1141–1150

Shiu YT, Li S, Marganski MA, Usami S, Schwartz MA, Wang YL, Dembo M, Chien S (2004) Biophys J 86:2558–2565

Ku DN, Giddens DP, Zarins CK, Glagov S (1985) Arterioscler Thromb Vasc Biol 5:293–302

Song JW, Gu W, Futai N, Warner KA, Nor JE, Takayama S (2005) Anal Chem 77:3993–3999

Acknowledgments

This research was supported by the Converging Research Center Program funded by the Ministry of Education, Science and Technology (2011K000864), and the Advanced Biomass R&D Center (ABC) of Global Frontier Project funded by the Ministry of Education, Science and Technology (2011-0031357).

Author information

Authors and Affiliations

Corresponding author

Additional information

J. S. Choi and Y. Piao contributed equally to the work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 2 (MP4 395 kb)

Rights and permissions

About this article

Cite this article

Choi, J.S., Piao, Y. & Seo, T.S. Fabrication of a circular PDMS microchannel for constructing a three-dimensional endothelial cell layer. Bioprocess Biosyst Eng 36, 1871–1878 (2013). https://doi.org/10.1007/s00449-013-0961-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-0961-z