Abstract

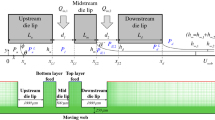

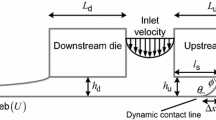

The viscoelastic-capillary model to predict approximately coating windows for the stable operations of viscoelastic coating liquids is derived using a lubrication approximation in slot coating processes. Pressure distributions and velocity profiles for viscoelastic liquids based on the Oldroyd-B and Phan-Thien and Tanner (PTT) models are solved in the coating bead region considering the Couette-Poiseuille flow feature and the pressure jumps at upstream and downstream menisci. Practical operating limits for the uniform coating of rheologically different liquids that are free from leaking and bead break-up defects are constructed under various conditions, incorporating the position of the upstream meniscus as an important indicator while determining limits. The shift of the uniform operating range shows different patterns for the Oldroyd-B liquid with a constant shear viscosity and the PTT liquid with a shear-thinning nature in comparison with the Newtonian case. The windows predicted by the simplified model are corroborated with experimental observations for one Newtonian and two viscoelastic liquids.

Similar content being viewed by others

References

Brethour J (2005) Simulation of viscoelastic coating flows with a volume-of-fluid technique, proceedings of the 6th European Coating Symposium, Bradford, UK

Carvalho MS, Khesghi HS (2000) Low-flow limit in slot coating: theory and experiments. AICHE J 46:1907–1917

Chu V, Tsai MZ, Chang YR, Liu TJ, Tiu C (2010) Effects of the molecular weight and concentration of poly (vinyl alcohol) on slot die coating. J Appl Polym Sci 116:654–662

Cruz DOA, Pinho FT, Oliveira PJ (2005) Analytic solutions for fully developed laminar flow of some viscoelastic liquids with a Newtonian solvent contribution. J Non-Newton Fluid Mech 132:28–35

Gates ID (1999) Slot coating flows: Feasibility, quality. PhD thesis, University of Minnesota

Higgins BG, Scriven LE (1980) Capillary-pressure and viscous pressure-drop set bounds on coating bead operability. Chem Eng Sci 35:673–682

Ji HS, Ahn WG, Kwon I, Nam JW, Jung HW (2016) Operability coating window of dual-layer slot coating process using viscocapillary model. Chem Eng Sci 145:122–129

Jin GL, Ahn WG, Kim SJ, Nam J, Jung HW, Hyun JC (2016) Effect of shim configuration on internal die flows for non-Newtonian coating liquids in slot coating process. Korea-Aust Rheol J 28:159–164

Koh HJ, Kwon I, Jung HW, Hyun JC (2012) Operability window of slot coating using viscocapillary model for Carreau-type coating liquids. Korea-Aust Rheol 24:137–141

Landau L, Levich L (1942) Dragging of a liquid by a moving plate. Acta Physicochim Urs 17:42–54

Lee SH, Kim SJ, Nam JW, Jung HW, Hyun JC (2014) Effect of sloped die lip geometry on the operability window in slot coating flows using viscocapillary and two-dimensional models. J Coat Technol Res 11:47–55

Lee SH, Koh HJ, Ryu BK, Kim SJ, Jung HW, Hyun JC (2011) Operability coating windows and frequency response in slot coating flows from a viscocapillary model. Chem Eng Sci 66:4953–4959

Lee AG, Shaqfeh ESG, Khomami B (2002) A study of viscoelastic free surface flows by the finite element method: Hele-Shaw and slot coating flows. J Non-Newton Fluid Mech 108:327–362

Morrison FA (2001) Understanding rheology. Oxford University Press, New York

Nam JW, Carvalho MS (2010) Flow in tensioned-web-over-slot die coating: effect of die lip design. Chem Eng Sci 65:3957–3971

Ning CY, Tsai CC, Liu TJ (1996) The effect of polymer additives on extrusion slot coating. Chem Eng Sci 51:3289–3297

Phan-Thien N, Tanner RI (1977) A new constitutive equation derived from network theory. J Non-Newton Fluid Mech 2:353–365

Ro JS, Homsy GM (1995) Viscoelastic free surface flows: thin film hydrodynamics of Hele-Shaw and dip coating flows. J Non-Newton Fluid Mech 57:203–225

Romero OJ, Scriven LE, Carvalho MS (2006) Slot coating of mildly viscoelastic liquids. J Non-Newton Fluid Mech 138:63–75

Romero OJ, Suszynski WJ, Scriven LE, Carvalho MS (2004) Low-flow limit in slot coating of dilute solutions of high molecular weight polymer. J Non-Newton Fluid Mech 118:137–156

Ruschak KJ (1976) Limiting flow in a pre-metered coating device. Chem Eng Sci 31:1057–1060

Saito H, Scriven LE (1981) Study of coating flow by the finite element method. J Comput Phys 42:53–76

Sartor L (1990) Slot coating: fluid mechanics and die design. PhD thesis, University of Minnesota

Schmitt M, Baunach M, Wengeler L, Peters K, Junges P, Schafer P, Schabel W (2013) Slot-die processing of lithium-ion battery electrodes—coating window characterization. Chem Eng Process 68:32–37

Schweizer PM, Kistler SF (1997) Liquid film coating. Chapman & Hall, New York

Sibley DN (2010) Viscoelastic flows of PTT fluids. PhD thesis, University of Bath

Silliman WJ (1979) Viscous film flows with contact lines: finite element simulation, basis for stability assessment and design and optimization. PhD thesis, University of Minnesota

Song D, Gupta RK, Chhabra RP (2010) Effects of shear-thinning and elasticity in flow around a sphere in a cylindrical tube. Comsol conference 2010, Boston

Tsuda T (2010) Coating flows of power-law non-Newtonian fluids in slot coating. Nihon Reoroji Gakkaishi 38:223–230

Weinstein SJ, Ruschak KJ (2004) Coating flows. Annu Rev Fluid Mech 36:29–53

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIP) (NRF-2016R1A5A1009592) and the Ministry of Trade, Industry & Energy (MOTIE, Korea) under the Industrial Technology Innovation Program (No. 10067082).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lee, Y.W., Ahn, WG., Nam, J. et al. Operability windows in viscoelastic slot coating flows using a simplified viscoelastic-capillary model. Rheol Acta 56, 707–717 (2017). https://doi.org/10.1007/s00397-017-1026-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-017-1026-z