Abstract

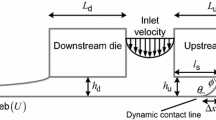

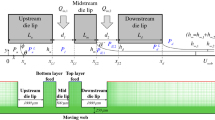

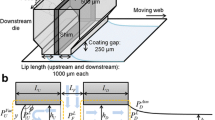

As an indicator for determining the operability window in slot coating flow, the viscocapillary model considering various configurations of upstream and downstream slot die lips was tested and compared with Navier–Stokes two-dimensional model. Bead pressure and sloped lip angle conditions for uniform coating operation demarcated from leaking and bead break-up defects were quantitatively predicted from the position of upstream meniscus from both models. By comparing the results, it is confirmed that the viscocapillary model for many kinds of sloped die lips could predict the operability window accurately. It is also found that there exists vortex or recirculation regimes inside upstream and downstream coating bead regions, depending on the angles of sloped die lips, even for the stable coating flow. The flow control by die lip structure will be usefully applied to design the strategy for the reliable and optimal coating process, including vortex-free windows.

Similar content being viewed by others

References

Cohen, ED, Gutoff, EB, Modern Coating and Drying Technology. VCH Publishers, New York (1992)

Sartor, L, “Slot Coating: Fluid Mechanics and Die Design.” PhD Thesis, University of Minnesota, Minneapolis (1990)

Kistler, SF, Schweizer, PM, Liquid Film Coating. Chapman & Hall, London (1997)

Lee, SH, Youn, SI, Lee, JS, Jung, HW, “Effect of Air Pressure Difference on the Stability and Sensitivity in Simplified Curtain Drawing Flow.” J. Chem. Eng. Jpn., 44 524–528 (2011)

Tjiptowidjojo, K, Carvalho, MS, “Viscocapillary Model of Slide Coating: Effect of Operating Parameters and Range of Validity.” AIChE J., 55 2491–2505 (2009)

Gutoff, EB, Cohen, ED, Coating and Drying Defects. Wiley, New York (1995)

Gates, IA, “Slot Coating Flows: Feasibility, Quality.” PhD Thesis, University of Minnesota, Minneapolis (1999)

Lee, SH, Koh, HJ, Ryu, BK, Kim, SJ, Jung, HW, Hyun, JC, “Operability Coating Windows and Frequency Response in Slot Coating Flows using Viscocapillary Model.” Chem. Eng. Sci., 66 4953–4959 (2011)

Nam, JW, Carvalho, MS, “Two-Layer Tensioned-Web-over-Slot Die Coating: Effect of Operating Conditions on Coating Window.” Chem. Eng. Sci., 65 4065–4079 (2010)

Lin, CF, Wong, DSH, Liu, TJ, Wu, PY, “Operating Windows of Slot Die Coating: Comparison of Theoretical Predictions with Experimental Observation.” Adv. Polym. Technol., 29 31–44 (2010)

Nam, JW, Carvalho, MS, “Mid-Gap Invasion in Two-Layer Slot Coating.” J. Fluid Mech., 631 397–417 (2009)

Koh, HJ, Kwon, IY, Jung, HW, Hyun, JC, “Operability Window of Slot Coating using Viscocapillary Model for Carreau-type Coating Liquids.” Korea-Aust. Rheol. J., 24 137–141 (2012)

O’Brien, WG, “Beveled Edge Metered Bead Extrusion Coating Apparatus.” US Patent 4,445,458 (1984)

Yeckel, A, Scriven, LE, “Multiparameter Continuation Methods for Tracking Desired Flow States.” Proceedings of the 1992 ACM/IEEE Conference on Supercomputing, Minneapolis, pp. 142–151 (1992)

Carvalho, MS, Kheshgi, HS, “Low-flow Limit in Slot Coating: Theory and Experiments.” AIChE J., 46 1907–1917 (2000)

Lin, CF, Wang, BK, Tiu, C, Liu, TJ, “On the Pinning of Downstream Meniscus for Slot Die Coating.” Adv. Polym. Technol., 32 E249–E257 (2013)

Lin, YN, Liu, TJ, Hwang, SJ, “Minimum Wet Thickness for Double-Layer Slide-Slot Coating of Poly(vinyl-alcohol) Solutions.” Polym. Eng. Sci., 45 1590–1599 (2005)

Chin, CP, Wu, HS, Wang, SS, “Improved Coating Window for Slot Coating.” Ind. Eng. Chem. Res., 49 3802–3809 (2010)

Han, GH, Lee, SH, Ahn, WG, Nam JW, Hyun WJ, “Effect of Shim Configuration on Flow Dynamics and Operability Windows in Stripe Slot Coating Process.” J. Coat. Technol. Res., doi:10.1007/s11998-013-9485-3 (2013)

Ruschak, KJ, “Limiting Flows in a Pre-Metered Coating Device.” Chem. Eng. Sci., 31 1057–1060 (1976)

Higgins, BG, Scriven, LE, “Capillary-Pressure and Viscous Pressure-Drop Set Bounds on Coating Bead Operability.” Chem. Eng. Sci., 35 673–682 (1980)

Middleman, S, Fundamentals of Polymer Processing. McGraw-Hill, New York (1977)

Kistler, SF, Scriven, LE, “Coating Flow Theory by Finite Element and Asymptotic Analysis of the Navier–Stokes System.” Int. J. Numer. Methods Fluids, 4 207–229 (1984)

de Santos, JM, “Two-Phase Cocurrent Downflow through Constricted Passage.” PhD Thesis, University of Minnesota, Minneapolis (1991)

Romero, OJ, Carvalho, MS, “Response of Slot Coating Flows to Periodic Disturbances.” Chem. Eng. Sci., 63 (8) 2161–2173 (2008)

Nam, JW, Scriven, LE, Carvalho, MS, “Tracking Birth of Vortex in Flows.” J. Comput. Phys., 228 4549–4567 (2009)

Carvalho, MS, “Roll Coating Flows in Rigid and Deformable Gaps.” PhD Thesis, University of Minnesota, Minneapolis (1996)

Romero, OJ, Scriven, LE, Carvalho, MS, “Effect of Curvature of Coating Die Edges on the Pinning of Contact Line.” AIChE J., 52 447–455 (2006)

Acknowledgments

This study was supported by research grants from the Industrial Strategic Technology Development Program (10035163) and the Human Resources Development of Korea Institute of Energy Technology Evaluation and Planning (KETEP: No. 20114010203050).

Author information

Authors and Affiliations

Corresponding authors

Additional information

This paper was presented at the 16th International Coating Science and Technology Symposium, September 9-12, in Atlanta, GA (USA).

Rights and permissions

About this article

Cite this article

Lee, S.H., Kim, S.J., Nam, J. et al. Effect of sloped die lip geometry on the operability window in slot coating flows using viscocapillary and two-dimensional models. J Coat Technol Res 11, 47–55 (2014). https://doi.org/10.1007/s11998-013-9504-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-013-9504-4